Change Language :

Durable 3D-Printed Gears

Up to 80% more wear-resistant than conventional plastics

While standard gears from stock often satisfy the needs of industrial applications, just as often a more unique solution is needed, whether due to size constraints or the need for custom geometries. This is where 3D printing shines, and the 3D-printed gears available from igus® are particularly effective in industrial applications. This is because of the maintenance-free, wear-resistant materials used in igus’ 3D printing processes. These materials are 80% more wear resistant than conventional plastics, and don’t require relubrication or other routine maintenance. Whether you’re looking for a quick prototype, a bulk order of 10,000 pieces, or something in between, igus can deliver exactly what you’re looking for.

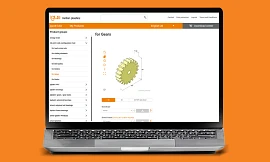

Upload a 3D model (STL/STEP). Select material, printing method and get pricing.

Upload not working? Click here to start the upload directly in the 3D printing service tool.

Gear Types

With the igus 3D printing service, every type of wear-resistant and self-lubricating gear drive can be produced quickly and independently of mechanical tools. In addition to conventional models such as spur gears, worm wheels and bevel gears, the laser sintering procedure with iglide materials works very well for elliptical gears, crown gears, undefined, worm gears and much more.

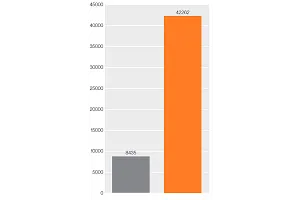

Plastic gears on the test rig

All polymer gear performance numbers come from the test rigs in our test laboratory. Here you can find the undefined based on various components.

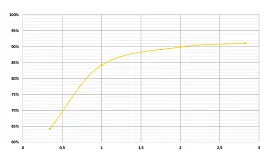

Very high efficiency for 3D printed gears made of high-performance polymer

Application Examples

For large series: iglide® injection-molded gears

3D printing isn’t always the best choice for part production, especially for large quantities of standard products. Injection molding is the better option in these cases due to low cost-per-part and rapid production time. Like other igus® products, our injection-molded plastic gears boast a number of advantages not available from other manufacturers.

The advantages at a glance:

- Cost-effective due to injection molding

- Maintenance-free and grease-free

- Long service life

- Low coefficients of friction

FAQ: Frequently Asked Questions

3D printed gears made of iglide polymers

A: You do not need a lubricant for 3D printed gears made of iglide polymers. The gear already contains lubricant.

A: Unlike the situation for bearings, wear is not the biggest problem for gears. For gears, the question is when the teeth will break off. That determines a gear's service life.

A: Tolerance depends on part dimensions. Parts up to 50mm have a tolerance of ± 0.1mm. Parts larger than 50mm have a tolerance of ± 0.2%. These values apply to non-reworked parts.

For the dimensioning of the fit on your shaft, it is necessary to know how torque is transmitted and what mechanism is used. If the shaft is 10x10mm, for example, a tolerance limit of 10.1mm would work for your gear.

A: Our calculation tool works only for gears with at least 17 teeth. Less than 17 teeth would require undercut information for the calculation, and our calculator has no option for adding or using it. If you need a gear with fewer than 17 teeth, contact your igus representative.

A: Yes, you can machine the parts if you need to.

A: Our gear service life calculation assumes that there is no additional lubrication.

A: Our minimum wall thickness is about 0.7mm. If necessary, we can go as low as 0.5mm. We can manufacture small worms and worm gears. If you have high loads, you will need metallic worm shafts.

A: We can print parts for which the teeth have been adjusted. This is not currently reflected in our configurator. If you need such gears and have no capability for designing them, don't hesitate to contact us.

A: The 5Nm are applied to the entire gear, not to the teeth.

A: You can use our gear configurator to create your gear.

A: We have extended our gear configurator, so that it is now possible to configure gears with a minimum number of eight teeth.

A: There is a small advantage if you do not consider the printing volume.

iglide FDM materials are good for bearings and other wear-resistant parts. Gears made of our laser sintering materials have a much longer service life.

The finished product can be machined like any conventional plastic.

A: Our minimum wall thickness is 0.7mm. If we need to, we can go as low as 0.5mm, but we normally recommend a minimum of 0.7mm.

We have tested many gears made of various POMs and other machined gears such as PPT, but the results were not better than those for POM in any respect.

A: The general rule for 3D-printed or polymer bearings is: if the application and load are not very great, the parts can be made of polymer. This rule also works very well for parts printed in 3D. But if the load or surface speed is very high, there comes a point at which the application will work only with a metal part running against a polymer part. At a certain point, it is better to have a metallic shaft because it conducts the heat from the tribological system better. Then the smaller gear should be made of metal because it is always the one with the greater load. The larger gear can be made of polymer, so the system remains without lubrication.

A: Both gears can be made of polymer and our service life calculator used to determine the point at which the system stops functioning well. There will be a point at which polymer gears no longer function well because the load is too high.

A: No, it doesn't. The solid lubricants are not affected by the heat. The same is true for injection moulding and bar stock materials, which also experience intense heat briefly during the manufacturing process without losing their self-lubricating properties.

Metallic gears can handle higher loads that polymer ones can. If you have a metal gear that is reaching the limits of what a metal gear can do, you cannot replace it with a polymer gear. That would require a gear three or four times the current size. But if the metallic gear is not at the limit of what metallic material can do, you can, of course, replace it with a polymer gear, and then you have a system that requires no external lubrication and for which you can receive any type of gear very quickly. You can use our service life calculator to determine whether this is the case for your application or not.

A: All parts printed at igus are solid, so they are 100% polymer and can be reworked. We produce solid parts because they are used as gears, bearings and whatever else in machines, and must therefore have the highest possible stability. You can, of course, also design lightweight components to reduce weight. If that is what you want, let us know, and then we won't print solid gears.

A: Sintered material is fairly rough, but smooths quickly during use, and the roughness does not impair the printed part's performance.

Contact Us

Questions or product information? Please contact:

Customer Service

Customer Service:

Phone: Monday to Friday from 8 am - 8 pm

LiveChat: 24 hours

Book a Call

Book an Appointment with a Product Expert