Change Language :

Custom-made component with assistance from the igus 3D printing service

Application Overview

Fast delivery thanks to online configurator and laser sintering procedure

The online configurator simplifies 3D modeling, and SLS printing creates parts layer by layer with a laser melting plastic powder. This eliminates traditional machining, saving time and costs, especially for small batches.

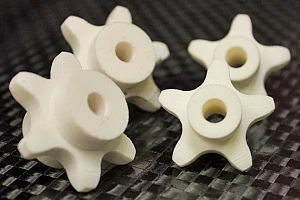

Robust components made of tribopolymers

Used as a chain tensioner in the motor's chain drive, the pinion must be very robust. Here, too, the iglide® tribo-polymers demonstrate their superiority to ordinary polymers. igus® developed the high-performance plastics specifically for dynamic industrial applications.

In this case, iglidur i6, which is more resistant to wear than common plastics for laser sintering printing, was used. The material's wear resistance was tested in the in-house test laboratory. The experts tested a worm wheel at 5Nm and 12rpm. The gear made of Polyamide 12, a classic material for laser sintering printing, failed after just 521 cycles due to its high coefficient of friction. iglidur i6, on the other hand, exhibited only minor wear after one million cycles and was fully functional.

Further application reports

Contact Us

Questions or product information? Please contact:

Customer Service

Customer Service:

Phone: Monday to Friday from 8 am - 8 pm

LiveChat: 24 hours

Book a Call

Book an Appointment with a Product Expert