Apart from the strand deposition process (FDM), the igus 3D printing service offers selective laser sintering as a manufacturing process for additively manufactured components. In the SLS process, a laser selectively heats spots in a powder bed that fuse together to form a previously constructed, three-dimensional object. A blade redistributes the powder after each melted layer. This process doesn't require tools, which is reflected in both the price and the speed of production.

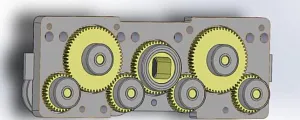

Components manufactured via the SLS process show very precise dimensional accuracy as well as high strength and good layer bonding. For "The Box" by Levita, the attention to detail in the printing was particularly important - without it, the change in tolerance from 0.2mm to 0.1mm would not have been possible.