Why print gears from iglide® i3?

iglide® plastic, engineered for moving machine parts, offers exceptional abrasion resistance and built-in solid lubricants. Used in injection molding, additive manufacturing, and machining, it ensures durability across applications. iglide® i3, a high-strength powder for laser sintering, is igus’ top-selling 3D printing material due to its superior wear resistance.

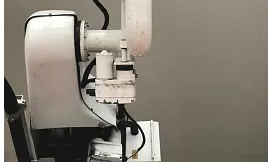

Ideal for spur and bevel gears, iglide® i3 provides long-lasting performance, while iglide® i6 is best suited for 3D-printed worm gears requiring enhanced sliding properties. The online gear service life calculator helps determine durability under specific conditions.

A major advantage of 3D-printed gears is the ability to optimize the tooth root geometry, extending service life—something typically limited in traditional machining. For precise customization, igus® offers a free CAD configurator to streamline gear design.