Change Language :

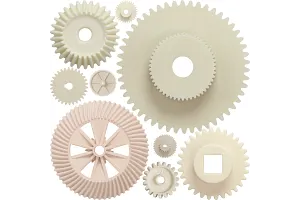

Small installation space, big challenge: 3D-Printed Gears

Customized solution for searchlights thanks to the 3D printing service from igus®

Police and rescue teams often rely on roof-mounted swivel searchlights for nighttime operations, allowing them to illuminate surroundings without leaving the vehicle. To stand out from competitors, Standby GmbH developed a more compact, high-performance searchlight.

3D printing at igus®: Precise solutions with a long service life

In many sliding applications, small-format components offer mechanical or aesthetic advantages. A creative, fine structural design of a product requires a manufacturing method that fulfils the design requirements precisely and cost-effectively. The additive manufacturing of components through the aligned melting of powder layers characterises the SLS process, which delivers sliding components with a wall thickness of up to 0.7 mm.

Contact Us

Questions or product information? Please contact:

Customer Service

Customer Service:

Phone: Monday to Friday from 8 am - 8 pm

LiveChat: 24 hours

Book a Call

Book an Appointment with a Product Expert