igus acquires cable assembly and harnessing specialist elko

Thanks to expanded production capacities, companies can receive the right harnessed cable for their application even faster

12 FEBRUARY 2025 – igus®, the world leader in motion plastics, moving cable, and cable management systems, has announced the acquisition of elko Verbindungstechnik GmbH. With this step, the company is expanding its assembly capacities in the field of drive technology. At the same time, the motion plastics specialist from Cologne is now even closer to its customers in southern Germany, the center of the German machine tool and automotive industry.

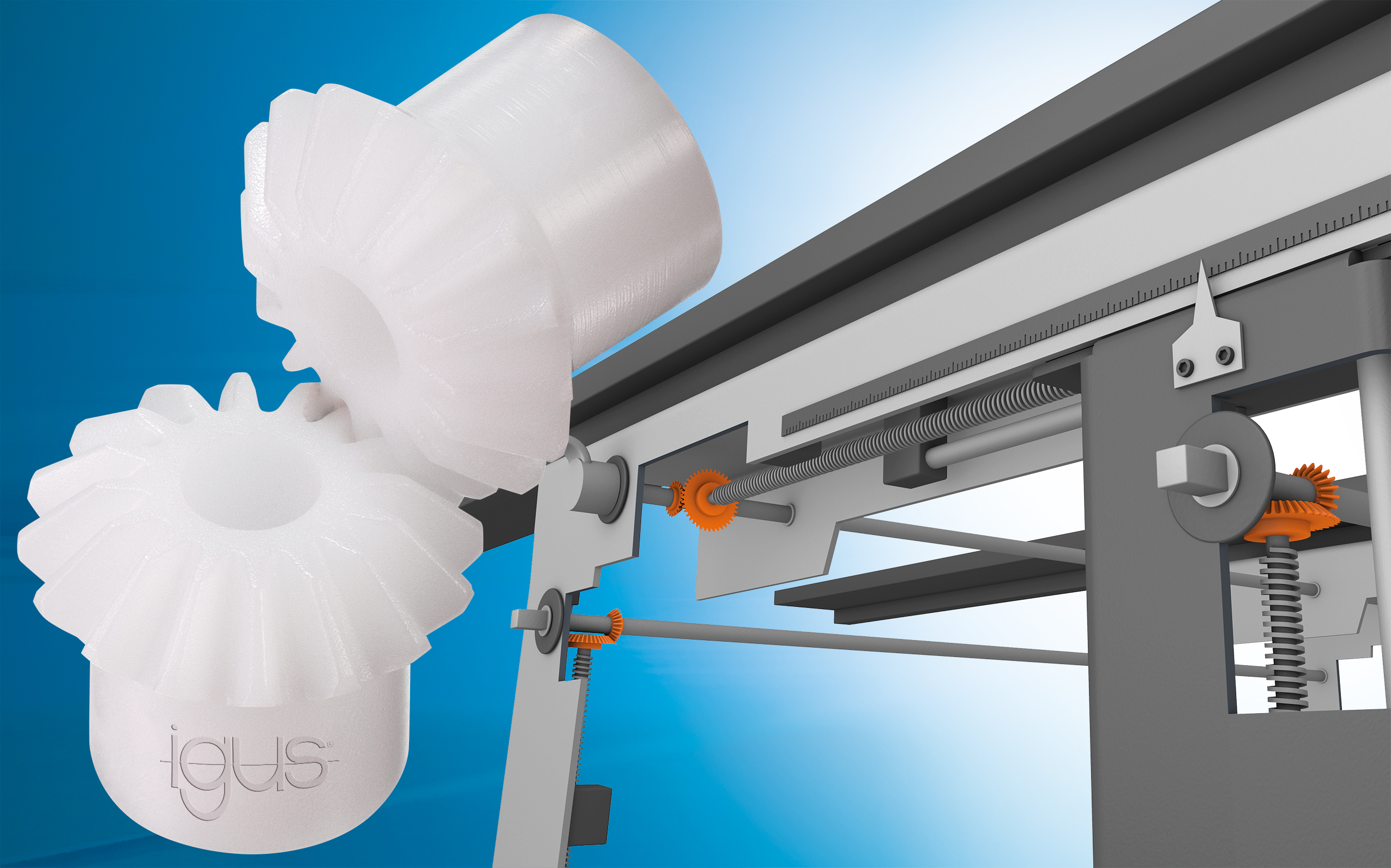

The harnessing of cables for moving applications is a core competence of the motion plastics specialist igus. These are manufactured according to industrial standards or customized specifications. For cables, igus draws on its extensive chainflex® range, which is used in combination with well-known connector manufacturers such as Harting, Binder, TE Intercontec, Yamaichi, and many others.

With almost 6,000 harnessed motor, servo, signal, and encoder cables for use in e-chain® cable carriers and suitable for 40 manufacturer standards, igus offers the right drive cable for almost every application. The harnessed readycable® cables guarantee a long service life thanks to extensive tests and quality checks in the 4,000m2 test laboratory and more than 25 years of experience igus has in manufacturing and assembling cables.

Customized harnessing solutions delivered immediately

In January 2025, igus acquired elko Verbindungstechnik GmbH. Like igus, elko is an owner-run company and an expert in connection technology. The company from Kirchheim am Necker specializes in assembling cables and plug-in connectors into customer-specific systems and cable sets, which are used primarily in mechanical engineering and the automotive industry. Thanks to its geographical location and good transport links, the location in Kirchheim am Neckar offers ideal conditions for geographical proximity to customers and even better service.

“Being close to our numerous clients in southern Germany enables igus to be even more flexible and respond more quickly to individual requirements,” emphasizes Michael Blass, igus CEO e-chain systems. “The regional proximity allows for even more direct and personalized customer service.”

This proximity to customers and their applications is important for developing innovative and customized solutions for a wide range of application scenarios. It is important to pay close attention to the specific requirements of the respective application.

“There is no one-cable-fits-all; the operating conditions and location play a decisive role in choosing the best cable,” says Christian Stremlau, Head of readychain® and readycable® at igus. “We always look for the most cost-effective solution that works.”

Merger strengthens both partners

With the acquisition of elko, igus is also expanding its production capacities through more production space and consistent automation of production processes. The result is a manufacturing network with minimal throughput and delivery times.

Currently, igus harnesses over 14,000 cables per week in Germany alone. In total, readycables are harnessed at 14 international igus locations worldwide – including the United States.

“We made a very conscious decision to purchase elko,” emphasizes Stremlau. “elko is an owner-run company that has grown steadily and is characterized by its committed employees who put their heart and soul into their work. It is a company with character and tradition, with strong relationships to its customers. It is deeply rooted in the region.”

igus would like to thank Harwig Nuß and Markus Grözinger, who founded the company in 1998, for their trust, and feels a great sense of responsibility to use the joint strengths and resources to always offer all customers even better service and even better products.”

Stremlau is convinced that the merger of igus and elko will strengthen both companies.

“We look forward to working with the friendly and ambitious elko team and their current CEOs to ensure that customers have quick access to the best harnessed cable that works reliably in their moving application,” concludes Blass.