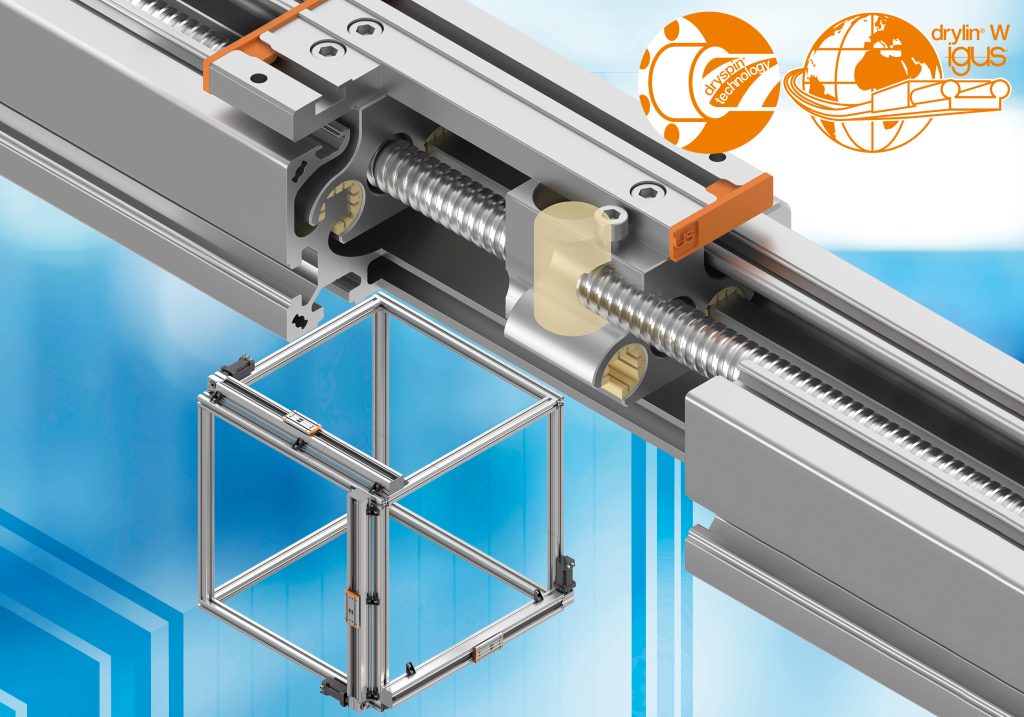

igus Introduces drylin® SLX Linear Axis with Lead Screw Drive for Heavy-Duty, Self-lubricating Applications

New drylin SLX-8060 linear actuator from igus handles up to 600kg (1,323lbs) with reduced assembly time and zero lubrication

April 16, 2025 – igus®, the global leader in motion plastics, has launched the drylin® SLX-8060, a ready-to-install linear axis equipped with a dryspin® lead screw drive. The corrosion-resistant system can handle axial loads of up to 600kg (1,323lbs), making it ideal for logistics, robotics, and manufacturing applications in packaging and automated material handling.

Designed to simplify and accelerate assembly, the SLX-8060 can be mounted directly to aluminum construction profiles without pre-drilled holes. This feature and its compatibility with both manual and electric drive components significantly reduce design and installation time.

“The SLX-8060 builds on the success of our ZLX linear axis, which was launched with a toothed belt drive in 2024,” said Matt Mowry, Product Manager for drylin Linear and Drive Technology at igus. “Engineers around the world provided positive feedback, particularly on the time savings during system integration. The new lead screw version expands our portfolio and offers even greater flexibility for customized machine design.”

Robust, Maintenance-Free Construction

The drylin SLX-8060 features an anodized aluminum high-profile rail integrated with a drylin® W linear guide system in installation size 16. It utilizes the dryspin lead screw drive, which can be operated electrically with DC, brushless DC, and stepper motors or manually, using angular gearboxes or safety handwheels from the igus drive technology modular system. The system is also compatible with third-party motors.

Notably, the axis requires no external lubrication. Instead, it operates using liners and lead screw nuts made from high-performance plastic, which include microscopic solid lubricants for low-friction, dry running. This results in quieter operation, reduced susceptibility to dirt and contamination, and lower long-term maintenance costs. The “sliding instead of rolling” principle further reduces weight and enhances reliability.

“By eliminating the need for grease or oil, we have created a more fail-safe system,” Mowry added. “Three closed sides of the axis provide extra protection against dirt, making it ideal for demanding industrial environments.”

Tested for Durability and Performance

In the igus 5,500m² (59,202ft²) test laboratory, the drylin SLX underwent extensive long-term testing. The results demonstrated a lifespan of 113,232 cycles across 23,590 operating hours. The asymmetrical dryspin lead screw geometry enhances efficiency and increases service life by approximately 30%.

With installation size 16, the SLX-8060 achieves stroke lengths of up to 1,000mm and supports axial loads of up to 1,250N and radial loads of up to 5,000N. The large grooves in the profile enable easy integration of accessories such as sensor mounts and protective covers, providing additional versatility.

igus offers the SLX as a complete system with optional motor and control packages, ensuring fast deployment for automation and motion system developers.

More information about the drylin SLX-8060 linear axis can be found at: https://www.www.hansarobotics.com/product/22666?artNr=SLX-8060-16