Greeting Card Handwriting Robot with Linear Slides & Lead Screws

U.S. Engineering Firm Develops Handwriting Robot with Maintenance-Free Linear and Thread Technology from igus

11 FEBRUARY 2025 – Personalized communication in business is being redefined through automation. While emails and printed greeting cards often feel impersonal, a handwriting robot developed by Spline Product Development, an Arizona-based engineering firm, is transforming the way businesses connect with customers. By leveraging maintenance-free linear technology from igus, this innovative solution replicates human handwriting with precision, enhancing engagement and emotional impact.

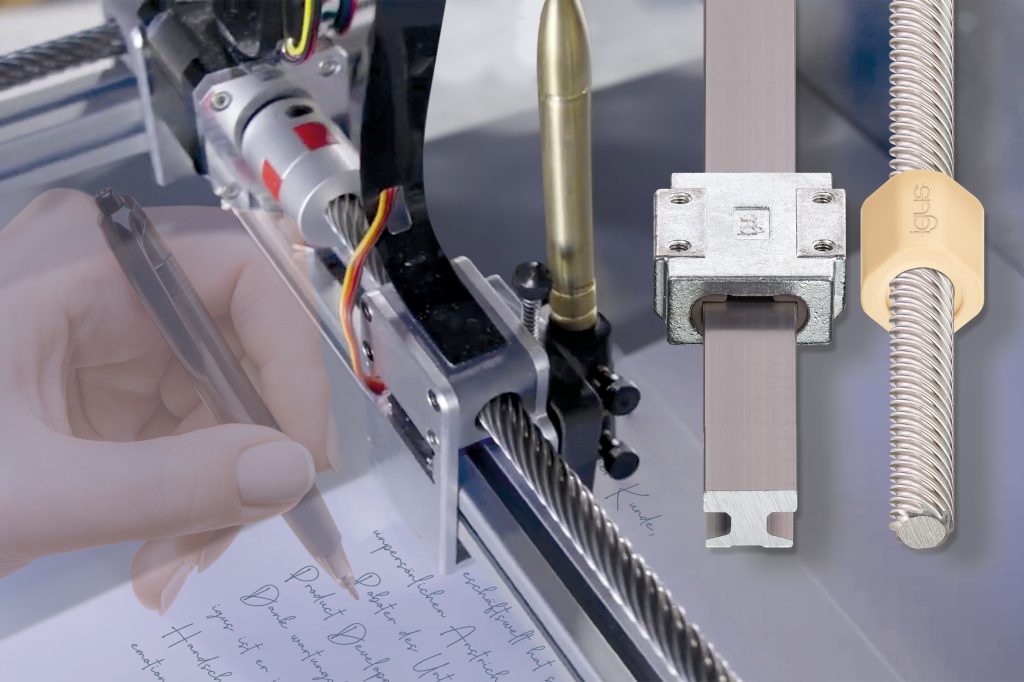

Currently in use at Simply Noted, a direct mail automation company based in Tempe, Arizona, the handwriting robot is designed to create authentic, handwritten messages at scale. Resembling a compact 3D printer, the system operates using three linear axes that control a ballpoint pen’s movement. The result is an exceptionally accurate replication of predefined handwriting styles, allowing businesses to send personalized correspondence with a human touch.

igus Linear Technology Enables Human-Like Handwriting

The development of the handwriting robot presented significant technical challenges. Early prototypes, though functional, suffered from slow performance and excessive wear, leading to increased maintenance costs and suboptimal writing quality. These limitations were addressed through the integration of igus linear technology.

A combination of drylin® T miniature linear guides, dryspin® lead screw drives, and electric stepper motors provided the necessary precision and durability. Two parallel linear guides approximately 50 cm apart support a third vertical guide. A pen is mounted on an additional carriage that moves horizontally along the third guide, allowing synchronized movement across the writing field.

The system’s precise motion is enabled by stepper motors that control the carriages at millimeter accuracy within milliseconds, ensuring highly detailed and consistent handwriting replication.

“The innovative geometry of the dryspin lead screws plays a crucial role in achieving this level of precision,” explains Michael Hornung, Product Manager for drylin Linear and Drive Technology at igus. “By flattening the thread flanks of the nut and spindle, an efficiency rate of 82% is achieved, improving positioning accuracy while maintaining smooth operation.”

This mechanical precision mimics the fine motor skills required for handwriting, which, in humans, involves over 30 different muscles in the hand, arm, and shoulder.

Reliability Through Self-Lubricating, Maintenance-Free Operation

Beyond precision, igus linear technology contributes to the robot’s long-term reliability and low maintenance operation. Unlike traditional linear guides, which require frequent lubrication, the drylin system operates completely lubrication-free. High-performance plastic components within the lead screw nuts and sliding elements contain embedded solid lubricants, ensuring consistent, frictionless movement without external grease or oil.

“This self-lubricating feature allows the handwriting robot to function reliably, even in environments where dust and debris are present,” Hornung adds. “In contrast to lubricated systems, where dirt accumulation can negatively impact performance, the igus solution eliminates this risk, ensuring uninterrupted operation.”

As a result, thousands of personalized messages can be produced with minimal downtime, offering businesses a cost-effective and scalable alternative to traditional handwritten correspondence.

For more information about igus motion control solutions, visit https://www.www.hansarobotics.com/linear-actuators

Video: https://youtu.be/E_tcBL0zw2E