Change Language :

Plastic e-chain® cable carriers reduce downtime & increase service life of cables

Plastic e-chain® cable carriers are more durable and longer lasting than the plastic carriers you’re used to. That’s because they’re made of highly engineered plastic materials that are put through 10 billion test cycles each year inside our 41,000 sqft. test lab at our headquarters in Cologne, Germany. We also offer readychain® pre-assembled with chainflex® high flexible cables that can reduce costs and assembly time by up to 95%.

E4Q e-chains® for tool-free assembly

E4Q is the newest generation of e-chain®. Based on the e-chain® standard E4.1, the new series offers a long service life, a high level of modularity and new technology within the crossbars which facilitate tool-free assembly.

The crossbars feature an easy to open mechanism which does not require any tools. Simply, lift the latch with your thumb on each end to remove and snap it shut to attach. This innovative new solution cuts the assembly time by up to 40% compared to the standard E4.1 e-chain®.

Browse e-chain® cable carriers

e-chain® cable carrier online tools

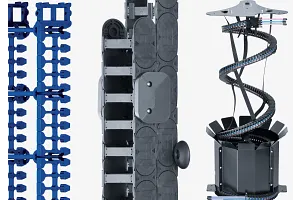

e-chain® cable carriers come in a variety of sizes ranging from 5mm inner height for the smallest installation spaces up to 350mm inner height for high loads. Find solutions for long, gliding and unsupported travels as well as for horizontal, vertical, zig zag and robotic applications. We also have open or closed systems with easy-to-open crossbars enables fast filling, and interior separators help increase the lifetime of the cables and hoses. Use the lifetime Calculator to determine the service life of your e-chain® cable carrier.

Applications for e-chains®

e-chains® are essential in industries such as manufacturing, automation, and material handling. They ensure cables and hoses are safely guided through complex movements, reducing wear and tear and minimizing maintenance costs.

e-chain® news 2025

Tech up, cost down: we will always give you at least one of the two. We have been pursuing this goal for you for many years. This year, we are presenting our new innovative energy supply systems that make the operation of your machines even better and more cost-efficient:

- cradle-chain E2.1.CG: the first energy chain made from 100% recycled material.

- Drive chain for extremely long and dynamic travels with long operating times

- e-spool for stage and theater applications

- guidelok swing - cable guidance

Installation and Inspection aka Orange Services

Proper installation is essential for the life of your cable carrier, and igus® has a team of dedicated engineers ready to assist you every step of the way. From site inspection, to installation, to complete modernization, our team will ensure the longest possible service life for your cable carrier system.

Contact us at (800) 521-2747 to discuss your project today!

Browse the Engineer's Toolbox

Frequently Asked Questions

Energy chains (also called energy supply chains, e-chains®) are mechanical machine elements. They are used to guide and protect energy, data and signals that have to withstand the most diverse environmental influences. The decisive fact about cable guides is the symbiosis of the components moving against each other. They include cables, hoses, interior separation elements, strain relief devices and guide troughs. The materials used have to be optimally matched to each other so that maximum operating times and a long service life are achieved. Thanks to energy chains, downtime is avoided wherever energy in the form of electricity, gas, air or fluids is supplied to moving loads.

Simply use our service life calculator to determine the expected service life of the energy chain.

We recommend using the expert configurator to determine the correct e-chain® based on the fill package, movement, and environment.

Rol e-chains® can travel or more 1,200m.

As a rule, the standard temperature range for plastic energy chains is -40°F to +240°F.

A detailed list provides information on the resistance of igus® igumid G, TE, and NB materials to many chemical substances.

Yes, the autoglide system allows travels of up to 80 m without guide troughs.

Yes, all igus® e-chains® materials can be deployed in continuous use at temperatures as low as -40°F

Contact Us

Questions or product information? Please contact:

Customer Service

Customer Service:

Phone: Monday to Friday from 8 am - 8 pm

LiveChat: 24 hours

Book a Call

Book an Appointment with a Product Expert