What is gear hobbing?

Gear hobbing is a cornerstone of modern manufacturing, enabling the creation of gears essential to machinery in the automotive, aerospace, and industrial sectors. This machining process stands out for its precision, versatility, and efficiency. This article will explore the intricacies of gear hobbing, the tools and equipment involved, its benefits, applications, challenges, and the future of this indispensable technique.

What is gear hobbing?

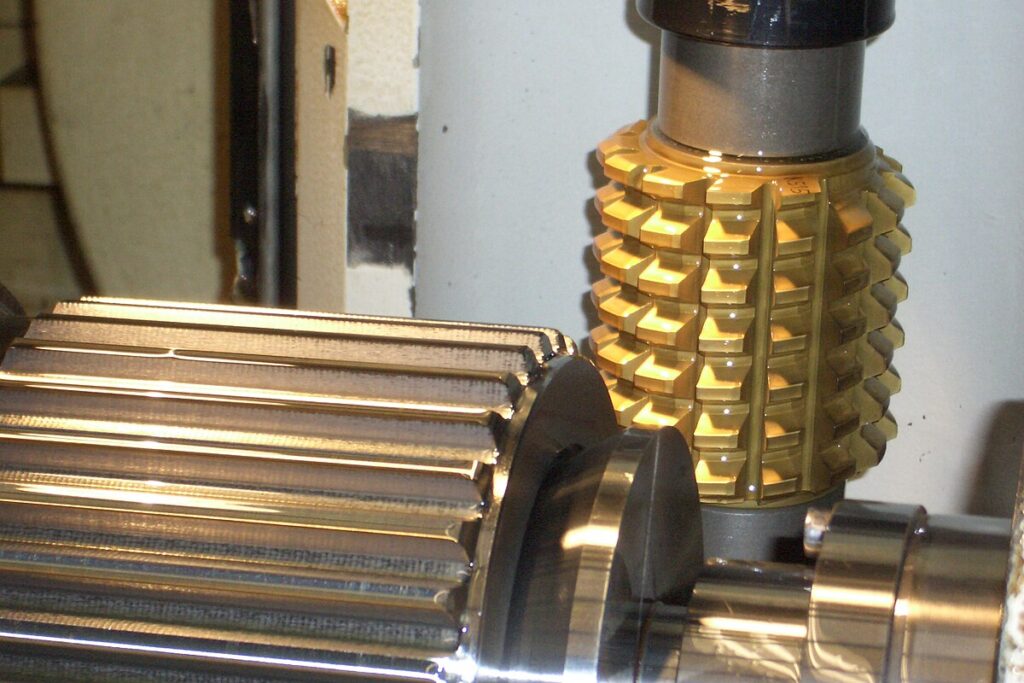

Gear hobbing is a specialized method of machining gears, splines, and sprockets. During gear hobbing, a tool called a hob — a cylindrical cutting tool with precisely arranged teeth — rotates in tandem with a gear blank, carving out the teeth of the gear in a highly controlled and synchronized manner.

Gear hobbing facilitates the production of gears with unmatched consistency and accuracy. Unlike some other gear production methods, hobbing can handle high-volume production while maintaining strict quality standards.

This makes hobbing an essential process for applications that demand high-performance gears, such as automotive drivetrains, aerospace systems, and robotic actuators.

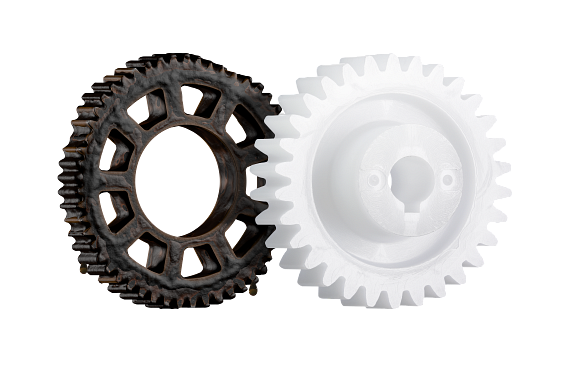

However, other gear production methods such as 3D printing and injection molding can achieve geometries not possible with hobbing. These methods can also make use of a much wider range of materials than those used in gear hobbing.

How gear hobbing works

Gear hobbing revolves around synchronized movement. The gear blank — a cylindrical piece of metal — and the hob cutter are mounted on skewed spindles. Once both spindles are aligned, they both begin to rotate, and the hob moves along the surface of the gear blank, gradually shaping the teeth of the gear.

Both the speed and alignment of the hobbing machine will change depending on the type of gear being manufactured.

Key steps in the gear hobbing process include:

- Setting up the gear blank and hob cutter: Accurate alignment is critical to ensure precision.

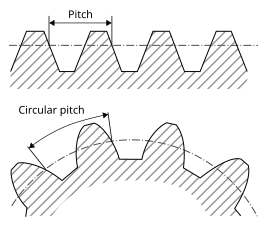

- Synchronizing rotations: The gear blank and hob cutter rotate at a specific ratio to define the gear’s tooth count and profile.

- Cutting teeth progressively: As the hob moves along the blank, its teeth cut deeper with each rotation, eventually shaping the final gear profile.

The hobbing process requires careful calculation of parameters such as the pitch, speed, and depth of cut to achieve the desired specifications.

Tools and equipment used in gear hobbing

The hob cutter

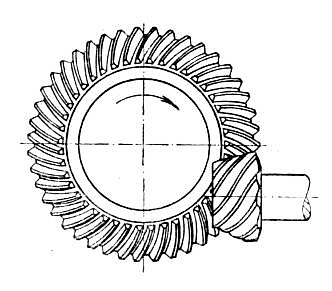

The hob is a cylindrical cutting tool with a helical design. Its teeth are carefully engineered to match the specific gear type being manufactured. For example, a hob designed for spur gears differs in geometry from one used for helical gears.

Hobs can be coated with materials like titanium nitride to enhance durability and reduce wear.

Gear hobbing machines

Both manual and CNC gear hobbing machines are available, with each favoring different production requirements and designs. Manual hobbing machines are ideal for small-scale production with more straightforward designs. CNC gear hobbing machines can handle much more complex design requiring greater precision and accuracy.

Auxiliary tools

- Lubricants & coolants: Essential for reducing heat and friction, extending tool life, and ensuring smooth operation.

- Alignment gauges: Used to verify the correct setup of the hob and gear blank.

- Fixtures and clamps: Secure the workpiece in place during machining to maintain accuracy.

Advantages of gear hobbing

Efficiency

Gear hobbing is one of the fastest methods for producing gears. The ability to cut teeth in a single setup — along with the ability to stack multiple blanks to be machined at once — significantly reduces production time compared to other methods.

Precision and versatility

Hobbing can produce a wide range of gears, from simple spur gears to intricate helical, cycloid, and worm gears. The hobbing process ensures consistent tooth geometry, which is essential for smooth operation and reduced wear.

Related: Helical gears vs. spur gears & their applications

Cost-effectiveness

The efficiency of hobbing minimizes labor costs and energy consumption. Additionally, the durability of hobs and the reduced need for secondary finishing processes, such as grinding, lapping, or shaving, contribute to long-term savings.

Challenges with gear hobbing

Material limitations

Harder materials, such as certain alloys and composites, can accelerate tool wear, requiring frequent hob replacement or the use of specialized coatings to mitigate wear.

Precision requirements

High-end applications, like those in the aerospace and robotics industries, require extremely tight tolerances. Achieving this demands advanced machinery and meticulous setup, increasing production complexity.

Tool wear and maintenance

The hob cutter is subject to wear over time, especially during high-volume production runs and when working with hard materials. Regular maintenance and replacement are necessary to maintain quality, which can increase operational costs.

Common applications of gear hobbing

Automotive industry

Gear hobbing is central to producing gears for transmissions, differentials, and power steering systems. These gears must endure high stresses and deliver precise performance, making hobbing the ideal choice.

Aerospace sector

Aerospace gears demand extreme precision and reliability. Gear hobbing enables the production of lightweight yet durable components essential for aircraft engines and navigation systems.

Industrial machinery

Heavy-duty gears used in conveyor systems, presses, and mining equipment often rely on hobbing for their durability and accuracy.

Robotics & automation

With the rise of robotics, the demand for compact, high-precision gears has surged. Gear hobbing meets these requirements, supporting advancements in automated systems.

The future of gear hobbing

Advancements in CNC technology

CNC-controlled gear hobbing machines are transforming the industry. These machines offer enhanced accuracy, faster production cycles, and the ability to create complex gear profiles with minimal manual intervention.

Sustainability in gear manufacturing

Manufacturers are adopting eco-friendly practices, such as using biodegradable lubricants and energy efficient machines, to reduce the environmental impact of gear production.

Emerging materials and coatings

Innovations in material science, including improved hob coatings and advanced alloys, are improving tool life and expanding the range of machinable materials.

Learn more: Wear-resistant plastic gears made of high-performance polymers

Adapting to industry needs

As industries evolve, so do the demands for more specialized and efficient gears. Gear hobbing is adapting through innovations like additive manufacturing integration and AI-driven process optimization.

Conclusion

Gear hobbing continues to be a cornerstone of modern manufacturing, delivering unmatched efficiency, precision, and versatility. From automotive gears to aerospace components, its applications are vast and vital. With ongoing advancements in technology and sustainability, gear hobbing is poised to remain at the forefront of gear production, shaping the future of manufacturing.