Understanding hypoid gears: design, benefits, and applications

When it comes to gear design, hypoid gears stand out as a unique and highly effective solution for certain mechanical systems. This blog will break down hypoid gear design, discuss how hypoid gears compare to bevel gears, and cover some advantages, disadvantages, and common application areas of hypoid gears.

What are hypoid gears?

Hypoid gears were developed in the early 1900’s once precision machining technology had advanced enough to create the complex tooth profile needed. Mathematical concepts of hypoid gears had existed for nearly a century prior.

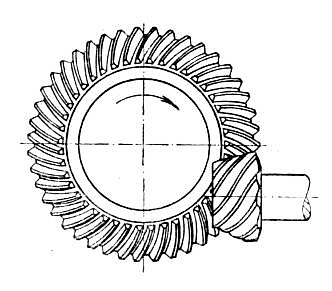

Hypoid gears are a specific type of spiral bevel gear, with one key distinction: their axes do not intersect. Instead, the pinion gear (smaller gear) is offset from the center axis of the larger gear.

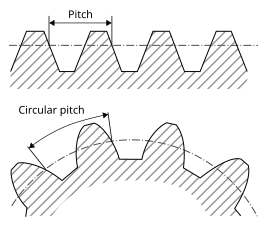

In a hypoid gear set, the smaller gear has a greater helix angle than the larger gear. As a result, exceptionally high gear ratios can be achieved, making it especially effective for high-speed reduction using a single set of hypoid gears.

Related: How does gear reduction work?

Hypoid gears vs. bevel gears

Bevel gears — both straight and spiral designs — have intersecting axes. Hypoid gears, on the other hand, have non-intersecting and non-parallel axes, giving them a distinct design advantage. This offset allows for a larger pinion diameter, which results in greater surface contact between the teeth. The increased contact area translates to smoother operation and a higher load-carrying capacity compared to traditional bevel gears.

Further reading: Types of gears: how they work and where to use them

Advantages and disadvantages of hypoid gears

Advantages

- Higher Torque Capacity: The larger pinion size and increased tooth contact area of hypoid gears allow them to handle higher torque loads, making them ideal within heavy-duty applications.

- Smooth and Quiet Operation: Their design minimizes sudden tooth contact, reducing noise and vibration compared to straight gear designs.

- Compact Design: The offset of the pinion enables a more compact assembly, which is valuable for space-constrained applications like automotive differentials.

Disadvantages

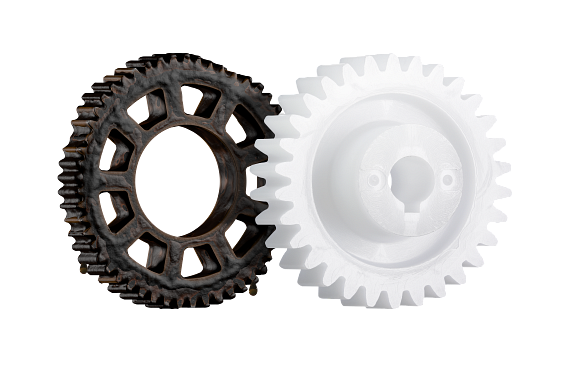

- Efficiency Loss: The sliding motion between teeth generates more friction, resulting in lower efficiency compared to bevel gears and making wear-resistant materials like iglide i6 vital.

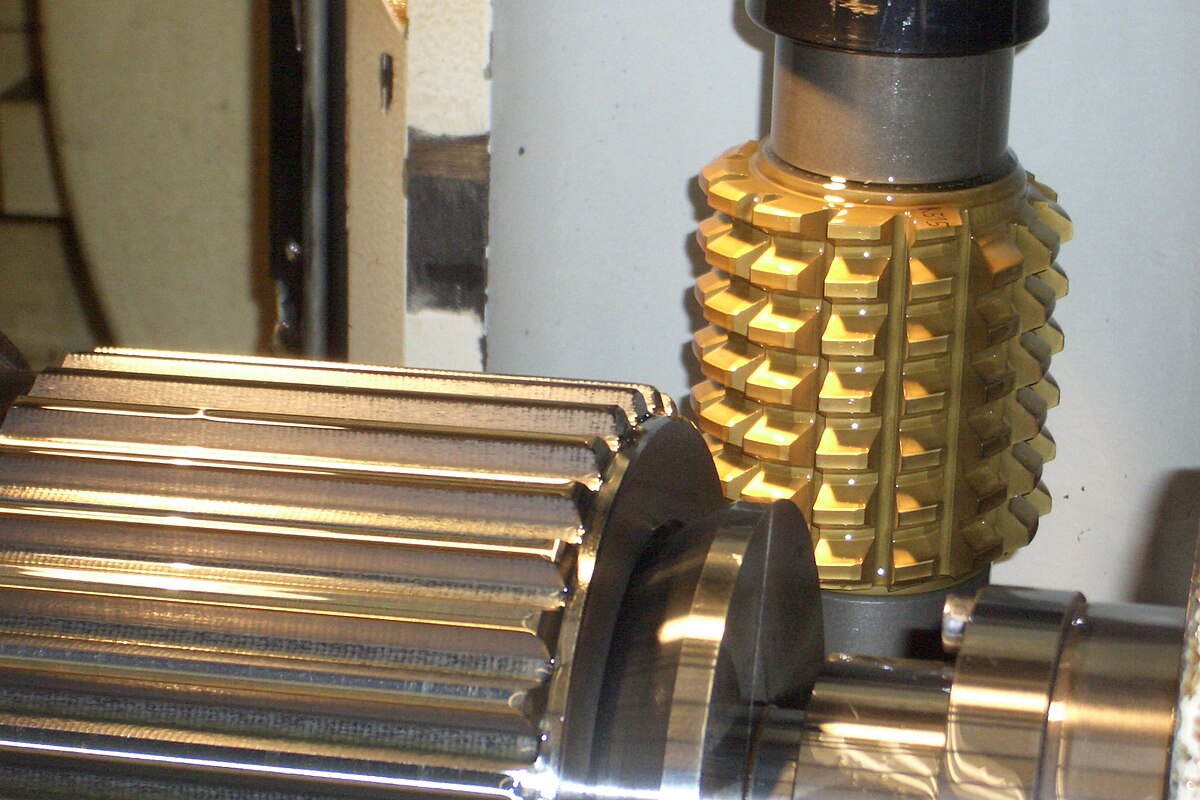

- Complex Manufacturing: Their design requires precise machining and specialized tools, increasing production costs — though 3D printing can be used to alleviate these costs.

- Lubrication Demands: The sliding action means hypoid gears need high-performance lubricants to prevent excessive wear.

Common applications of hypoid gears

Hypoid gears excel in applications where high torque transmission and compact design are critical. The most common and well-known application for hypoid gears is in automotive differentials, where they are often used in rear-wheel-drive axles to transfer power from the driveshaft to the rear axle.

Other areas of application that can benefit from hypoid gears are industrial machines like conveyors and mixers, where robust torque handling is necessary; aerospace applications that have both strict space constraints and load requirements; and robotic applications where smooth, low-noise operation is a priority.

Conclusion

Hypoid gears offer a unique blend of torque capacity, smooth operation, and compact design that makes them ideal in particularly demanding applications.

While they come with added complexity in manufacturing and lose some efficiency due to friction compared to straight bevel gears, their advantages often outweigh these drawbacks in the right context.