The crucial role of replacement gears in industrial applications

Gears play a crucial role in ensuring smooth and efficient operation in many industrial applications. When gears wear out or break, finding a high-quality replacement gear becomes essential to maintain the performance and longevity of the system.

This blog will delve into the importance of high-quality replacement gears, various methods of producing them, and examples of applications where replacement gears are beneficial.

Importance of high-quality replacement gears

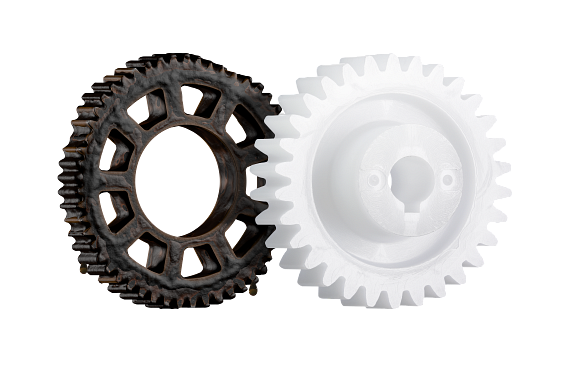

A high-quality replacement gear is vital for several reasons. Firstly, it ensures the continued efficiency and durability of the mechanical system. Poor-quality gears will lead to increased wear and tear, reduced performance, and even system failure.

High-quality gears, on the other hand, are designed to withstand the stresses and strains of industrial environments, providing reliable and long-lasting performance.

Moreover, using high-quality replacement gears can reduce maintenance costs and downtime. When gears are made from superior materials and manufactured to precise standards, they are less likely to fail prematurely, saving both time and money in the long run.

Additionally, high-quality gears contribute to the overall safety of the system, preventing accidents and ensuring smooth operation.

Common causes of gear failure

Understanding the common causes of gear failure is crucial for preventing issues and ensuring the longevity of mechanical systems. Some of the most common causes include:

Wear and tear

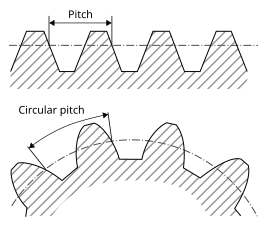

Over time, gears can experience wear and tear due to continuous operation and friction. This can lead to the gradual degradation of gear teeth, resulting in reduced performance and eventual failure.

Misalignment

Misalignment of gears can cause uneven distribution of forces, leading to excessive stress on certain areas of the gear. This can result in premature wear and failure.

Insufficient lubrication

Proper lubrication is essential for reducing friction and preventing wear. Insufficient lubrication can lead to increased friction, heat generation, and accelerated wear, ultimately causing gear failure. However, self-lubricating polymers can avoid issues of inadequate lubrication entirely.

Learn more: Self-lubricating polymer gears from igus®

Overloading

Gears are designed to operate within specific load limits. Overloading gears beyond their capacity can cause excessive stress and deformation, leading to failure.

Contamination

Contaminants such as dirt, debris, and moisture can enter the gear system and cause damage. Contamination can lead to increased wear, corrosion, and reduced performance.

Methods of producing replacement gears

There are several methods used to produce replacement gears, each with its own advantages and applications. Some of the most common methods include:

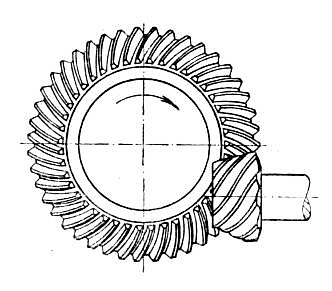

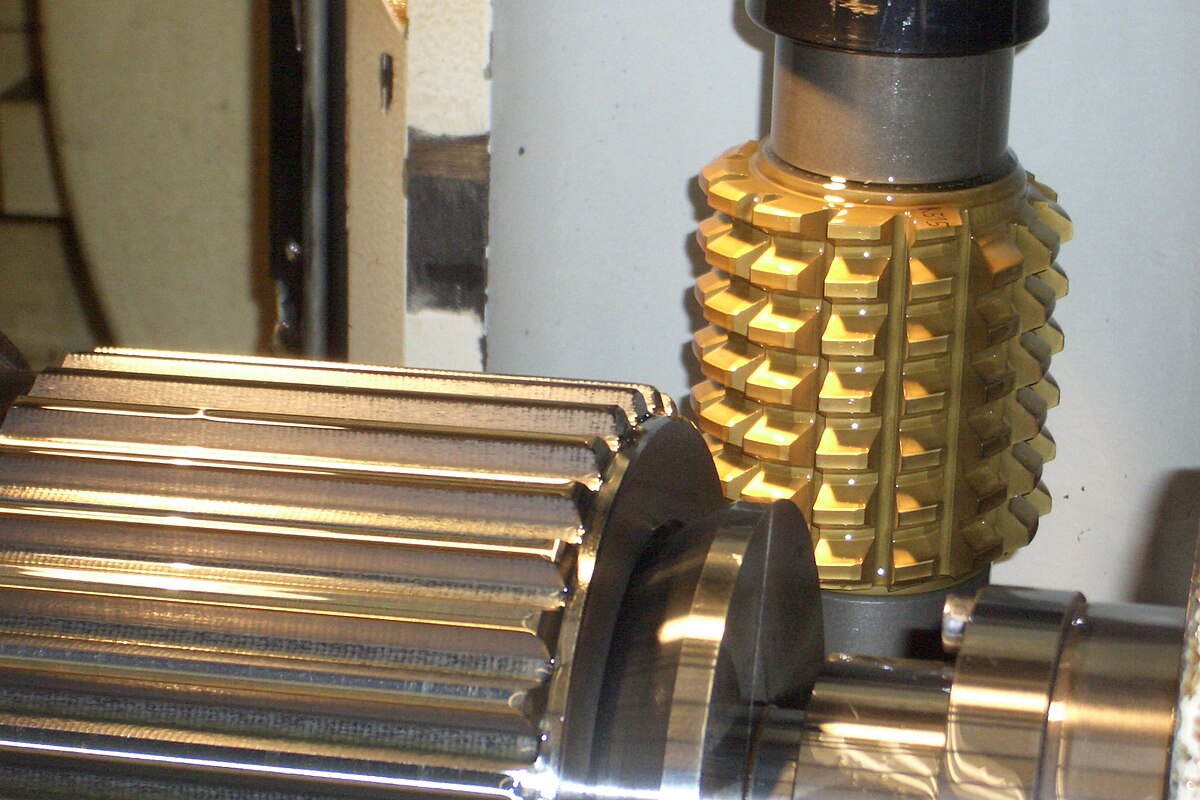

Gear hobbing

Gear hobbing is one of the most widely used methods for producing gears. It involves using a hob, a specialized cutting tool, to progressively cut the gear teeth into the blank gear material. This method is most often used for spur gears and helical gears.

Gear shaping

Gear shaping is another popular gear production method, where a high-speed reciprocating cutter shapes the gear teeth by removing material from the blank gear. This method is particularly useful for producing internal gears and gears with complex shapes, and is generally more accurate than gear hobbing.

Additive manufacturing

Additive manufacturing, or 3D printing, is becoming increasingly popular for producing replacement gears. This method allows for the creation of complex gear shapes and designs that would be difficult to achieve with traditional manufacturing methods. It also offers the advantage of rapid prototyping and customization.

Related: Durable 3D-printed gears from igus

Applications of replacement gears

Replacement gears are beneficial in a wide range of applications and situations. Here are a few examples:

Automotive industry

In the automotive industry, gears are used in transmissions, differentials, and other critical components. High-quality replacement gears ensure the smooth operation of vehicles, reducing the risk of breakdowns and improving overall performance.

Industrial machinery

Industrial machinery relies heavily on gears for various functions, such as power transmission and motion control. Replacement gears are essential for maintaining the efficiency and reliability of these machines, preventing costly downtime and ensuring continuous operation.

Aerospace industry

The aerospace industry demands high precision and reliability in its components. Replacement gears in aircraft engines and other systems must meet stringent standards to ensure safety and performance.

Consumer products

Gears are also found in many consumer products, such as appliances, power tools, and bicycles. High-quality replacement gears help extend the lifespan of these products, providing consumers with reliable and efficient performance.

Related: Planetary gears and their use in bicycles

Conclusion

The importance of high-quality replacement gears cannot be overstated. They ensure the continued efficiency, durability, and safety of mechanical systems, reduce maintenance costs, and provide reliable performance across various industries. By understanding the different methods of producing replacement gears and their applications, we can appreciate the critical role they play in our everyday lives.