igus Showcases PTFE-Free Materials and Sustainable Innovations at Hannover Fair 2025

igus Introduces Sustainable Motion Plastics to Reduce Costs and Environmental Impact

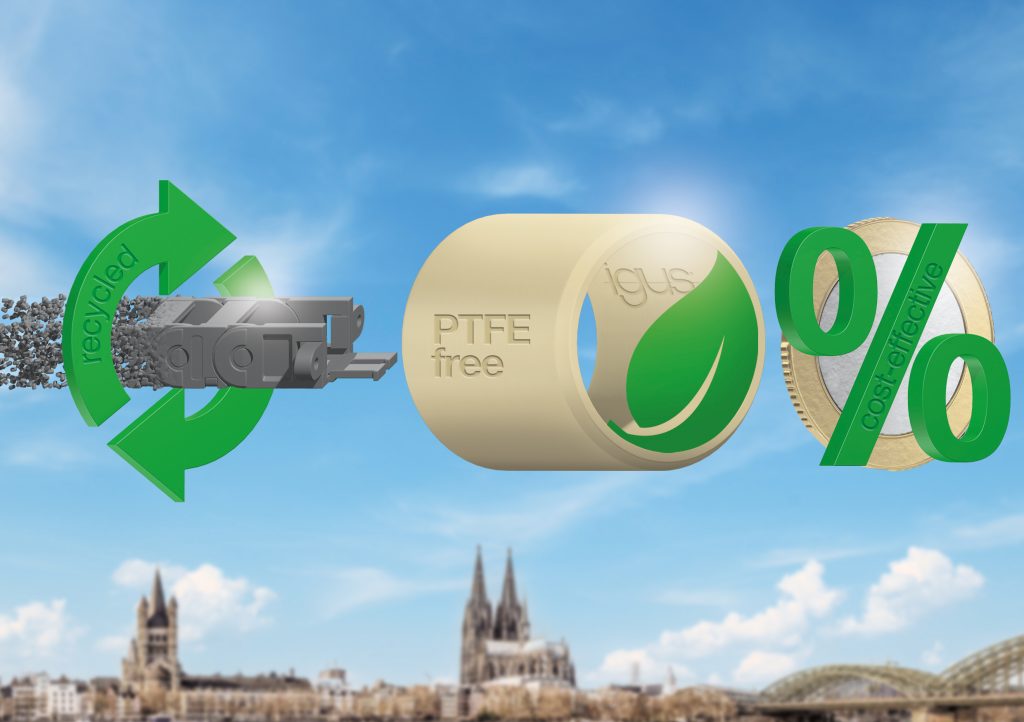

March 11, 2025 – At Hannover Fair 2025, igus® will present a series of innovative product developments to enhance sustainability and cost efficiency in industrial and automation applications. Among the highlights are newly developed PTFE-free materials, a complete cable carrier series manufactured from recycled materials, and a dry cleanroom certification for e-chain® cable carriers developed in collaboration with Fraunhofer IPA.

In response to economic uncertainties and increasing environmental regulations, igus continues to pioneer solutions supporting cost savings and sustainability without compromising quality.

“The evolving landscape of industrial production presents challenges but also opportunities for innovation,” said Tobias Vogel, CEO of Plain Bearing and Linear Technology at igus. “Our goal is to provide customers with solutions that enhance efficiency, promote sustainability, and remain competitively priced.”

Michael Blass, CEO of E-Chain Systems at igus, reinforced this vision: “By offering high-performance plastic components that eliminate the need for lubricating oil and grease, we help our customers reduce maintenance costs while protecting the environment. Our latest innovations demonstrate our commitment to sustainable, high-quality manufacturing.”

Transitioning to PTFE-Free Standard Materials

One of the most pressing sustainability challenges in the industry is the potential regulatory action on polytetrafluoroethylene (PTFE). In anticipation of possible restrictions, igus has invested years of research into developing viable alternatives.

“As part of our commitment to sustainable innovation, new formulations have been developed, extensive testing has been conducted, and production processes have been refined to ensure continued availability of high-performance solutions,” said Vogel.

The company has expanded its product range to include PTFE-free alternatives for all iglidur standard materials, including iglide® J, W300, M250, G, X, and H. Additionally, PTFE-free and PFAS-tested alternatives are already available in product lines such as linear guides, slewing ring bearings, and tribotape® liners.

Comparative analyses conducted in the igus test laboratory have demonstrated that these PTFE-free materials exhibit significantly improved friction and wear resistance over conventional PTFE-based alternatives, further enhancing their value in demanding industrial applications.

Advancing Sustainability with Recycled Cable Carriers

Following the successful introduction of the first e-chain made from recycled material in 2022, igus has expanded its sustainability efforts by converting its entire E2.1 standard e-chain series to igumid® CG LW, a material derived from post-consumer recycled plastics—this includes used cable carriers collected through the company’s “chainge” recycling program and discarded fishing nets.

“Through the development of this recycled chain series, customers are invited to participate in a circular economy model for plastics,” said Blass. “Sustainability does not have to come at a premium—our recycled E2.1 series is offered at the same price as the standard version, with no compromise in mechanical performance.”

Testing has shown that the recycled E2.1 series retains the durability and reliability of standard materials while achieving an 80% reduction in carbon dioxide (CO2) emissions during production.

New Cleanroom Certification and Emerging Technologies

igus continues to drive advancements in specialized industrial applications, including cleanroom environments for battery production. As demand for electric vehicles and lithium-ion batteries increases, manufacturers are faced with stringent cleanroom requirements.

“In dry cleanroom environments for battery production, conventional systems often require frequent replacement due to wear,” said Blass. In response to this challenge, igus introduced the E6.29 e-chain, the first to receive certification for use in dry cleanrooms.

In collaboration with Fraunhofer IPA, a new certification process has been developed to validate the long-term cleanroom suitability of igus e-chains. Testing has confirmed that even after 15 million double cycles or ten months of operation, the e-skin® soft SKS28 e-chain maintains ISO Class 4 cleanliness standards—the highest possible rating for this application. The E6 e-chain demonstrated similar durability, maintaining ISO Class 4 for an extended period before a slight downgrade to Class 5.

These innovations further establish igus as a leader in developing cleanroom-compatible automation solutions, reinforcing its reputation for advancing German engineering excellence.

Beyond cleanroom applications, igus remains at the forefront of industrial automation with developments in Low Cost Automation, automated guided vehicles (AGVs) for material handling, and the world’s first traveling shore power connection system for container ships.

Visit igus at Hannover Fair 2025

igus invites visitors to explore these innovations firsthand at Hannover Fair 2025 in Hall 6, Trade Show Stand E26.