igus reaches the one-billion mark in sales, increasing the number of active customers by 5%

€1.105 billion in sales and a record number of motion plastics products for 2025

2 APRIL 2025 – In 2025, igus® is introducing a record 277 motion plastics innovations, showcasing a variety of new lubrication-free plastic products under its motto “GO ZERO Lubrication.” These include PTFE-free materials, a complete energy chain series made from recycled materials, and even a humanoid robot. This achievement is a result of continuous investment in research and development, which aims to provide customers with cutting-edge solutions. Despite the challenging political and economic landscape of 2024, igus increased its number of active customers by 5% and maintained its billion-euro turnover. With sales reaching €1.105 billion ($1.19 billion), the company experienced a moderate decline in turnover of 2.5%.

“The changing political and economic conditions didn’t leave us entirely unaffected,” explains Matthew Aldridge, Managing Director at igus in Northampton. “Like many of our customers, we are also focusing on savings and increased efficiency. However, our focus is always on the question: ‘What’s in it for the customer?'”.

These challenges are an even greater incentive for us to break new ground and continue to drive innovation to reinforce our competitiveness and that of our customers. This year, igus is presenting a record number of innovations with 277 new motion plastics products – and is continuing to invest in the research, development, and production of new technical solutions. The entire igus campus in Cologne, where we produce, test, and research, now covers around 218,000 m2 (215278.2 ft2), with the new 20,000 m2 (215278.3 ft2) test laboratory being the largest in the industry.

Global investments for even greater customer proximity

igus continues expanding its global investments. Following the introduction of injection molding in the United States, igus is now establishing local lead screw production and opening an RBTX customer test area for low-cost robotics.

Additionally, igus is significantly expanding its Shanghai operations, increasing its footprint from approximately 25,000 m2 (269,097.8 ft2) to 45,000 m2 (484,375.9 ft2) with a new building.

With these expansions, eight countries now have dedicated testing facilities, enabling customers to quickly and easily find tailored Low-Cost Automation solutions locally. Three of these sites will further develop into regional hubs, promoting increased localization of production and development.

“The customer is at the center of all our activities,” emphasizes Justin Leonard, e-chain Director at igus UK. “For this reason, our investments are deliberately close to our customers.”

However, igus is also clearly focussing on customer proximity in Germany. With the takeover of elko Verbindungstechnik, igus is building up targeted assembly capacities in southern Germany. elko specializes in assembling cables and plug-in connectors for customer-specific systems used primarily in machine tools and the automotive industry. At their Cologne site, igus is also continuing to invest in new automation solutions to streamline processes and increase throughput times – with specifically developed and patented crimp towers or the use of AGVs in the factories.

On the right track to CO2 neutrality

igus has currently reached the 92% mark of its target to be CO2-neutral with its buildings and production by the end of 2025, measured against Scopes 1 and 2. “We need to become even better in this area and are working on numerous sustainability measures in Germany alone, from the new multi-story car park with complete façade greening to the modernization of our existing buildings, for example, with photovoltaic systems, to the expansion of our MHRS system for heating with waste heat from machines,” explains Aldridge.

277 new products for the future of industry

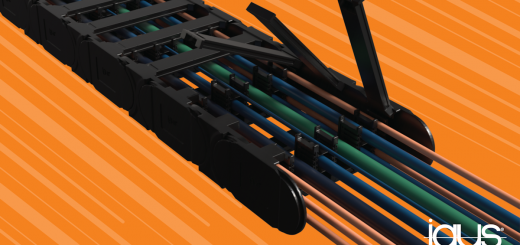

igus is presenting environmentally friendly solutions such as PTFE-free versions of the iglidur standard plain bearing materials G, X, and H. Regarding e-chains, igus is also converting its entire E2.1 series to recycled material consisting of post-consumer recyclates, such as old fishing nets, and disused cable carriers, which the company recycles as part of its own “Chainge” program — reducing the CO2 footprint by 80%.

With the igus Mobile Shore Power Outlet (iMSPO), igus has also developed a mobile “socket” for the shore power supply of container and cruise ships. The system is already in use in ports such as Hamburg, Rotterdam, and Singapore, and it has been nominated for this year’s Hermes Award at the German Trade Show. igus is also driving innovative solutions for dry cleanrooms, which is becoming increasingly important in battery production. Together with the Fraunhofer IPA, the company has developed a new type of certificate that confirms the cleanroom suitability of igus e-chains in long-term tests. They can withstand over 15 million cycles with minimal and consistent particle emissions.

In an economic climate where numerous companies face pressure to reduce costs, igus continues its commitment to innovation by developing cost-effective solutions for its customers. One notable advancement is the introduction of the new glide-chain G4.42 e-chain, specifically designed for straightforward gliding applications with travel lengths up to 30 meters (approximately 98 feet). Through optimized engineering, the G4.42 glide-chain is between 12% and 25% lighter and offers a cost reduction of 30% to 40% compared to conventional chains of identical dimensions from igus’s established E2 and E4 product ranges.

igus further demonstrates significant innovation through its development activities in low-cost automation. The company’s current project includes the creation of its first humanoid robot, manufactured entirely from high-performance plastic. This new robot builds upon the mobile ReBeL Move platform and incorporates ReBeL collaborative robots as its robotic arms. The humanoid robot, designed for versatile deployment across various workstations and locations, is anticipated to deliver a return on investment in less than one year.