Autonomous Logistics Robot Utilizes igus Polymer Bearings for Heavy-Duty Shelf Transport

Scallog’s Autonomous Robot Employs igus Polymer Bearings to Transport Shelves Weighing 1,325 pounds

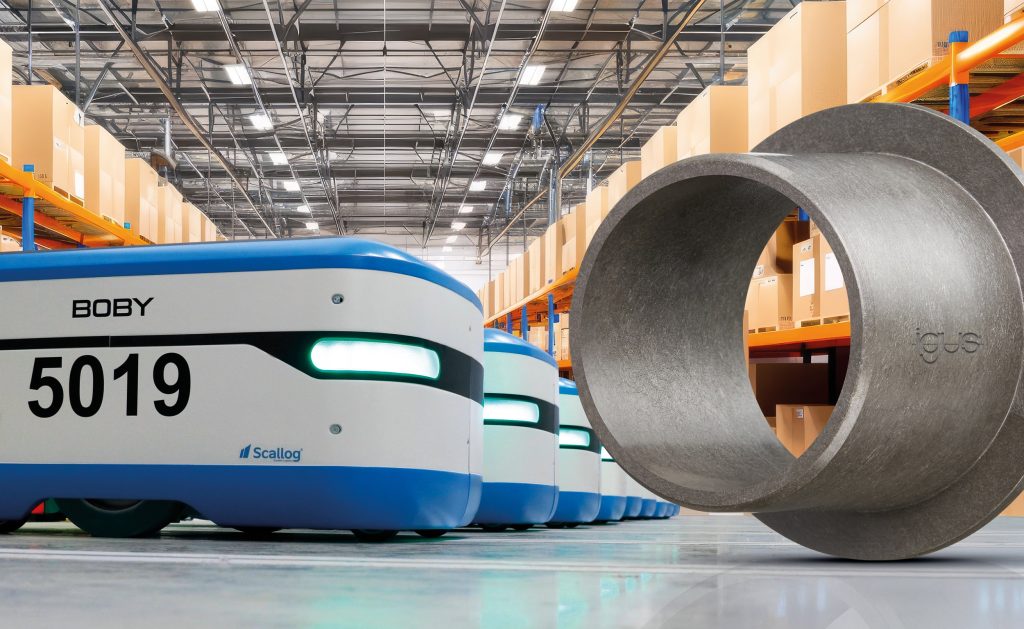

17 March 2025 – igus® is pleased to announce that Scallog, a leading French technology firm, has selected igus’ lubrication-free iglide® plain bearings for its autonomous logistics robot, “BOBY.” The BOBY mobile robot, engineered for warehouse applications, efficiently handles heavy-duty shelves thanks to igus bearings, which are recognized for their robust performance, extended durability, and significantly lighter weight compared to conventional metal alternatives.

In e-commerce logistics, manual order picking typically involves extensive physical exertion, with employees walking as much as 9 miles daily. Scallog’s autonomous solution addresses this challenge by improving worker performance and operational efficiency. The BOBY independently delivers shelves to picking stations, enabling workers to manage up to 600 picks per hour. Deployable individually or as part of a scalable robotic swarm, the BOBY robot reportedly enhances productivity by forty percent. The robot operates in various industrial sectors, including notable clients such as Decathlon, Farmy, Bricolux, and the Blondel Group.

The primary engineering challenge was selecting appropriate plain bearings for the robot’s scissor-joint lifting mechanism, capable of reliably supporting 1,325-pound shelves. Engineers required bearings that were not only highly robust but also maintenance-free, cost-efficient, and suitably compact for restricted installation spaces. iglide slide bearings from igus met these criteria due to their specialized high-performance polymer composition, which is optimized for friction and wear resistance. These polymer bearings demonstrated exceptional durability and reliability under high edge loads and impact conditions during extensive laboratory testing conducted by igus. Results from these evaluations are incorporated into an online tool, enabling users to predict product service life accurately.

igus polymer bearings offer significant advantages beyond mechanical robustness. The integrated solid lubricants within iglide materials eliminate the need for additional lubrication, reducing operating costs associated with labor, maintenance, and lubricant procurement. The self-lubricating nature of these bearings also contributes positively to environmental sustainability. Independent research from RWTH Aachen University confirms that igus bearings’ lubrication-free operation substantially decreases environmental impact and energy consumption throughout their lifecycle, ultimately reducing carbon footprint.

Operationally, the Scallog robot functions similarly to a drive-in counter. Once a warehouse employee initiates an order, the compact robots autonomously navigate beneath shelves, measuring 17.7 inches in height and 25.6 inches in width. Upon positioning, an integrated scissor mechanism elevates the shelves, which the robots then transport at speeds of up to 0.93 mph to designated picking stations. The robots are equipped with optical sensors that follow floor markings for precise orientation. Upon arrival at picking stations, the robots sequentially deliver shelves to employees, facilitating convenient and efficient order fulfillment.

The robots are equipped with optical sensors that follow floor markings for precise orientation. Upon arrival at picking stations, the robots sequentially deliver shelves to employees, facilitating convenient and efficient order fulfillment. Remarkably, BOBY robots can operate autonomously for up to 14 continuous hours without requiring battery recharging.