Clean Relief for Beverage Producers: Hygienic Linear Actuator by igus Enhances Safety and Efficiency

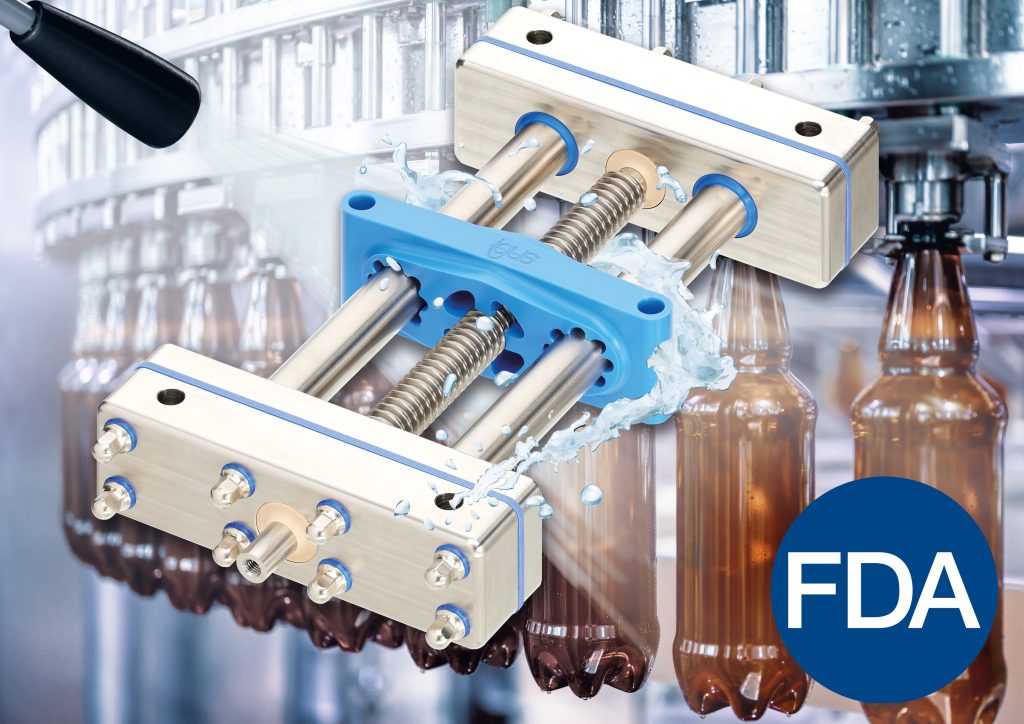

igus Introduces Self-Lubricating drylin® Linear and Drive Technology in Hygienic Design

(Source: igus)

8 January 2025 – The demand for hygienic, fail-safe, and low-maintenance solutions in the beverage industry continues to grow, driven by stricter global standards and increasing consumer expectations for safety. To address these challenges, igus has developed self-lubricating drylin® linear and drive technology, designed in accordance with European Hygienic Engineering & Design Group (EHEDG) guidelines. This innovative technology supports beverage manufacturers in achieving safe, efficient, and cost-effective production.

Addressing Industry Challenges with Hygienic Design

As regulatory standards evolve, beverage manufacturers must ensure that their production equipment—including components like linear technology—meets stringent hygiene requirements. These components play a crucial role in tasks such as filling, labeling, packaging, and inspecting.

“The demand for linear technology in hygienic design is rapidly increasing,” explains Michael Hornung, Product Manager for drylin® Linear and Drive Technology at igus. “Machine manufacturers are seeking ways to reduce contamination risks while minimizing cleaning efforts and operational costs.”

igus’s expanded portfolio includes products that align with EHEDG guidelines, emphasizing gap-free or encapsulated designs. These features facilitate thorough cleaning and help maintain high hygiene standards in beverage production facilities.

SHT Linear Actuator for Hygienic Positioning

A standout innovation in the portfolio is the SHT linear axis, designed for hygienic positioning tasks in filling stations. The module features stainless steel round shafts for guidance and dryspin® lead screw technology made of corrosion-resistant stainless steel for the drive. Key elements include:

- A truss assembly sealed with FDA-compliant silicone gaskets and hygienic screws

- Specially developed wiper seals that protect against dirt and moisture ingress

- Generous gaps in the lead screw nut design, enabling efficient cleaning

These features make the SHT linear module ideal for precise movements in beverage production environments.

“We are committed to consistently developing products that meet hygienic design standards,” Hornung states. “Our membership in EHEDG further supports our efforts to achieve certifications for open moving parts.”

Proven Technology for Food and Beverage Applications

igus’s dedication to innovation extends beyond the SHT linear module. The company introduced the world’s first sliding carriage for linear guides in hygienic design, made entirely of food-grade plastic, with FDA and EU 10/2011 approval. This system’s open design allows complete flushability, even with aggressive cleaning agents, and is suited for format adjustments in bottling plants to accommodate different bottle sizes without interchangeable parts.

Additional advancements include individual bearings within the drylin hygienic design product range, which offers flexibility through various sizes and configurations. Additionally, the drylin ZLW toothed-belt axis is constructed from stainless steel. It features plastic bearings and belts that comply with FDA and EU 10/2011 standards, ensuring suitability for hygienic applications.

igus components have already demonstrated success in diverse applications, such as inspection systems by Krones AG, robotic kitchens by Cook-e, and automated pizza ovens by BistroBox.

Advancing Safety and Efficiency in Production

By integrating solid lubricants into its high-performance plastic components, igus delivers solutions that operate without external lubrication, ensuring clean, low maintenance, and reliable performance. These innovations help beverage manufacturers comply with stringent hygiene standards while improving efficiency and reducing operational costs.

Hornung concludes: “With our lubrication-free linear and drive technology, designed for hygienic applications, we continue to meet the exacting requirements of the food and beverage industry, enhancing both safety and operational efficiency in production processes.”

For more information on igus’s hygienic design solutions, please visit: https://www.www.hansarobotics.com/product/22561