Change Language :

New plain bearing products from igus

Yet more tried-and-tested iglide® materials now without PTFE

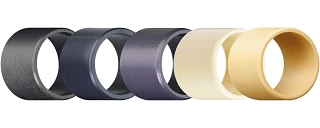

iglide® standards without PTFE

The PTFE-free versions of the bestsellers iglide® G for universal applications and iglide® X and H for high temperature and chemical contact now complement our PTFE-free plain bearing product range.

Cost-effective and extremely wear-resistant under high loads

iglide® W300E multi-component plain bearing

This high-strength 2-component injection-molded plain bearing is based on the universally applicable material iglide® W300 and is exceptionally strong and durable.

Quick to screw on, cost-effective and sliding

Gliding guide pads from iglide® GLW

The new glide pads are perfect for guiding aluminum or steel rails. They can be flexibly adapted thanks to their shape.

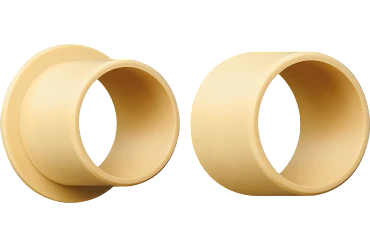

New material for extremely low bearing clearance

iglide® G2

The exceptionally low moisture absorption and thermal expansion combined with high dimensional stability enable very low bearing clearance (G9).

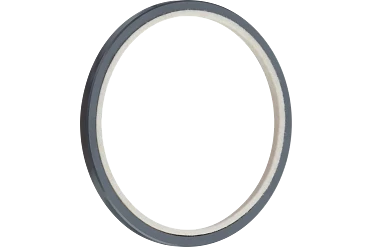

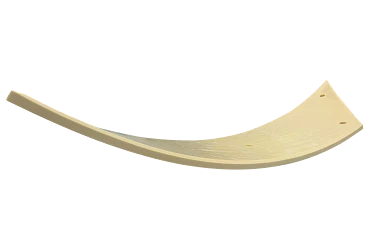

Universal sliding segments for any quantity

iglide® universal sliding segments

The flexible sliding segments made of the wear-resistant heavy-duty material iglide® Q3 enable any bearing diameter from 250mm.

Individually customisable and usable

Stainless steel mesh with iglide® coating

This flexible and robust stainless steel mesh with iglide® coating is customizable and ideal for various industrial applications. Also available as a plate in the dimensions 1,200 x 800mm.

Other new products that may also be of interest to you

For extreme endurance, now PTFE-free

iglide® W300PF

The newly developed material iglide® W300PF offers the performance of the proven endurance runner iglide® W300 - completely without PTFE.

Wear-resistant and flexible

Double flange bearing made of iglide® K230

The new material iglide® K230 offers lower moisture absorption and even more flexibility compared to the clip bearings made of iglide® M250

100% protected against dirt

iglide® SG-03

Thanks to the product range addition, the available diameters now include 30, 40, 50, 60 and 70mm.

Chemical-resistant, low-cost

iglide® C160 disc springs

With iglide® C160, disc springs are particularly resistant to chemicals and also cost-effective.

The proven endurance runner without PTFE

iglide® JPF

Based on the tried and tested endurance runner material iglide® J, iglide® JPF offers comparable specifications - without the use of PTFE.

iglide® FPF

For antistatic requirements, without PTFE

The new material iglide® FPF is not only conductive and therefore ideal for applications with ESD requirements, but also PTFE-free.

iglide® IC-05PF coating powder

The all-rounder with FDA and no PTFE

According to FDA, EU 10/2011 and - now new - without PTFE. With outstanding sliding and wear properties.

Now for all iglide® bearings

Calculate CO2 footprint for each component

CO₂ emissions must be determined and reduced in more and more areas. We support you in this: The CO2 emissions generated during the transport and manufacturing processes of our bearings can now be calculated and displayed for each iglide® plain bearing. This allows you to compare plain bearings and select the one with the lowest carbon footprint for your application.

Made from cost-effective regranulate for high loads

iglide® Q2LW

The regranulate version of the proven heavy-duty plain bearing material iglide® Q2 is perfect for price-sensitive applications with high loads.

When it needs to be particularly cost-effective

iglide® econ materials

The materials of the econ series, iglide® J4, GLW, P4, PLW210, ALW350, HLW and -new - Q2LW are not only ideal for many applications, but are now also available on the European market in standard dimensions.

Virtually unlimited diameters

iglide® "large bearings"

With the new bearing segments made of iglide® J, plain bearings with large diameters can be designed quickly and easily by means of postforming processes.

igutex TXH - flexible processing all round

High-load composite bearing with homogeneous structure

The new fiber composite material for high loads has a homogeneous layer structure and can therefore be processed and used on all sides.

Contact Us

Questions or product information? Please contact:

Customer Service

Customer Service:

Phone: Monday to Friday from 8 am - 8 pm

LiveChat: 24 hours

Book a Call

Book an Appointment with a Product Expert