Change Language :

FastLine: Bearings in Custom Dimensions, Within Weeks

With the igus® FastLine service, you can receive prototypes of injection-molded bearings, rollers, and more in as little as 2 weeks.

To determine if your bearing design is available with FastLine, input your dimensions and other requirements into our iglide® plain bearing designer, which shows you the manufacturing costs of our various production methods. If your desired plain bearings are already available in our standard product range, they will be included in the price comparison as well. That way, you can always keep an eye on the best price.

Benefits:

- Choose from over 30 iglide® wear-resistant bearing materials based on your application, industry & requirements

- Everything from 1 source: from injection mold to final product

- Price comparison between all our manufacturing methods

(injection molding, machining, 3D printing) to save you money - Environmentally-friendly: no grease or lubricants needed

- Good coefficient of wear ensures longer service life

Upload a 3D model (STL/STEP). Select material, printing method and get pricing.

Use the Bearing Designer to

Access the FastLine Service

Choose bearing type, material and input dimensions to see pricing for 3D SLS-printed, injection molded, barstock and machined options. Pricing and delivery times will also be shown for the FastLine service option, if possible with your dimensions and application requirements.

You can also upload a CAD file by using the drag & drop above.

Advantages of iglide® materials

- 100% dry-running and maintenance-free

- Corrosion-resistant

- 80% weight-saving compared to metal

- Precisely predictable service life

- Tested in the industry's largest test laboratory under realistic application conditions

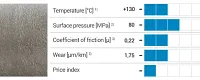

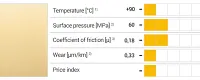

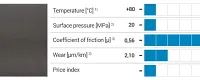

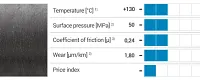

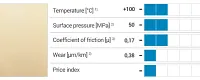

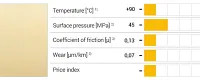

Our Most Popular iglide® Materials

Explore some of the 30+ material options that are available with the FastLine option in our Bearing Designer tool.

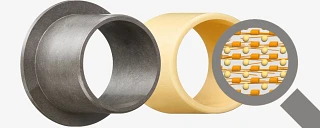

Available Geometries

Not only are most of our iglide materials available for FastLine, but you can also request custom dimensions for a multitude of shapes, including sleeve bearings, flange bearings, belt rollers, thrust washers, wear rings, and clip bearings. Please note that not all materials are available for all geometries.

Contact Us

Questions or product information? Please contact:

Customer Service

Customer Service:

Phone: Monday to Friday from 8 am - 8 pm

LiveChat: 24 hours

Book a Call

Book an Appointment with a Product Expert