What are the different types of linear actuators?

On the surface, explaining what a linear actuator is to someone should be a simple prospect. Reality, however, is never so simple. While at the core, linear actuators are devices used to convert energy into linear motion, there are several different types of linear actuators that each create this motion in a different way. In this blog we’ll take a look at four of the most common types of linear actuators, how they work, and the differences between them.

Belt-driven linear actuators

Belt-driven actuators, as you may be able to deduce, are actuators that use a tensioned belt to drive the linear motion. Belt-driven actuators can either be operated manually or connected to a stepper or DC motor for automated operation. They’re ideal for high speed, low load applications, particularly when long strokes are required. Belt-driven actuators do need to be properly tensioned, regardless of if they’re manually or automatically operated. Thankfully, the video below explains how to do so quickly and easily.

Gantry robots—drylin® gantries from igus®, for example—often use belt-driven actuators as opposed to screw-driven ones, as they require high speeds and don’t typically need to carry excessive loads, but the specific application will determine which is the optimal choice. In certain cases, a combination of both is the best solution.

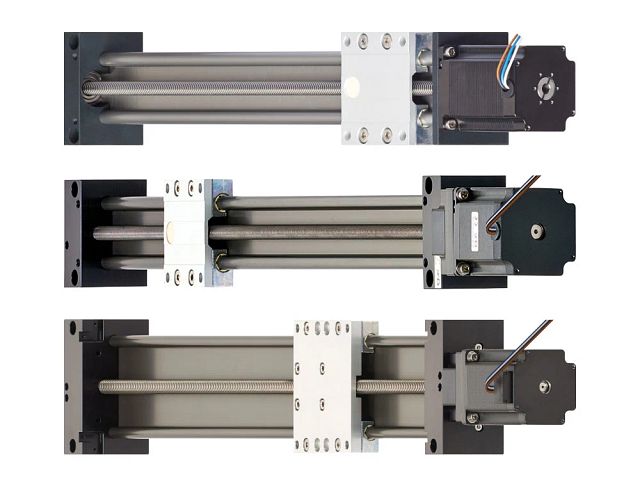

Screw-driven linear actuators

Screw-driven actuators operate similarly to their belt-driven counterparts, except the driving component is instead a lead screw (ball screws can also be used, but this blog will be exclusively covering lead screw-driven actuators). Like with belt-driven actuators, screw-driven actuators can be operated either manually or with a motor, depending on the needs of the application in question. They’re best used in applications requiring high accuracy over short travel distances (up to about five feet).

Guidance for screw-driven actuators can either be provided with parallel shafts or a fully supported linear guide rail, with both options providing different benefits. Linear rails are more rigid and resistant to torsion than parallel shafts, but parallel shafts are often available in a wider range of materials. Parallel shafts also allow dirt to fall away from the actuator more easily than it could from an actuator using a guide rail, making them better suited for heavy-duty applications where dirt is abundant.

Rack and pinion linear actuators

Rack and pinion actuators consist of a gear rack and a pinion gear. As the gear rotates and engages with the gear rack, it drives the rack forward or backward, creating precise and controlled linear movement. Rack and pinion actuators offer durability, high load capacity, and can operate in various environmental conditions, including heavy-duty and high-temperature applications.

These actuators are available in both pneumatic and electric configurations to suit different power and control needs.

Hydraulic linear actuators

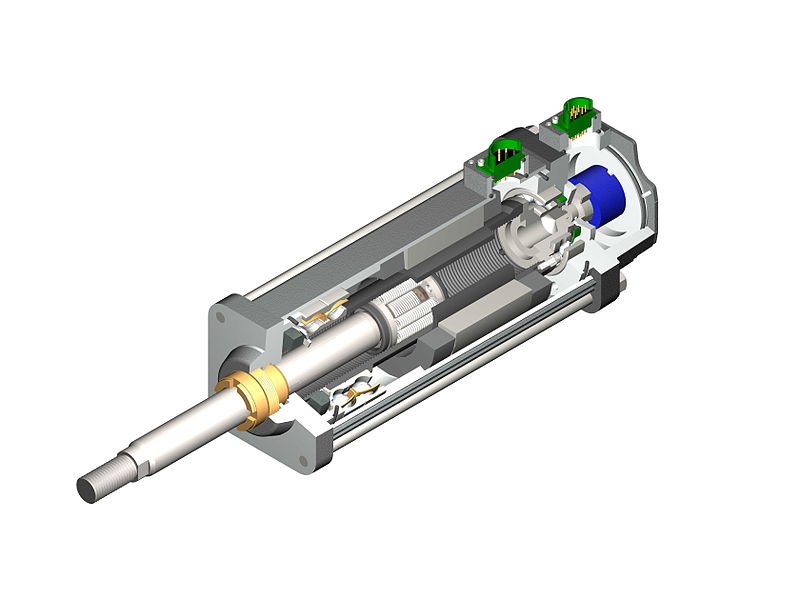

Hydraulic actuators are configured differently than mechanical actuators like the belt and screw-driven actuators previously mentioned. Hydraulic actuators consist of a piston inside a cylinder, and a connected pump supplies an incompressible hydraulic fluid that moves the piston, generating motion. Due to the fluid being incompressible, a constant force can be maintained without needing to supply continuous fluid. However, hydraulic actuators can suffer leaks that lead both to a loss of pressure and issues with cleanliness, making them a higher maintenance option than pneumatic and mechanical actuators. Hydraulic actuators are ideal for high-force applications, being able to generate 25 times more force than a pneumatic actuator of the same size, and can achieve up to 4000 psi of pressure.

Hydraulic actuators are configured differently than mechanical actuators like the belt and screw-driven actuators previously mentioned. Hydraulic actuators consist of a piston inside a cylinder, and a connected pump supplies an incompressible hydraulic fluid that moves the piston, generating motion. Due to the fluid being incompressible, a constant force can be maintained without needing to supply continuous fluid. However, hydraulic actuators can suffer leaks that lead both to a loss of pressure and issues with cleanliness, making them a higher maintenance option than pneumatic and mechanical actuators. Hydraulic actuators are ideal for high-force applications, being able to generate 25 times more force than a pneumatic actuator of the same size, and can achieve up to 4000 psi of pressure.

Pneumatic linear actuators

Pneumatic actuators work very similarly to hydraulic actuators, with the key difference being pneumatic actuators utilize pressurized air rather than hydraulic fluid. They’re much simpler than hydraulic actuators, though they do require a compressor to run constantly to maintain air pressure. This simple composition makes pneumatic actuators a more cost-effective option than nearly any other type of actuator, and can be operated in extreme temperatures due to the relative safety of air compared to hydraulic fluid or electricity.

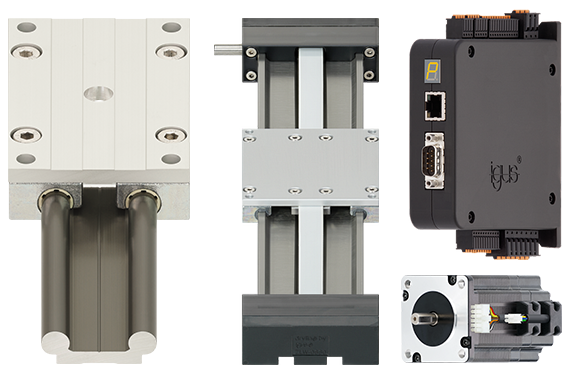

Electric linear actuators

Electric linear actuators are devices that transform electrical energy into linear motion, allowing for precise, straight-line movement. These actuators are commonly used in applications where accuracy and controlled motion are essential, such as in robotics, medical equipment, and industrial automation. By using an electric motor to drive a linear system, electric actuators can provide consistent, adjustable positioning with minimal maintenance.

Some key advantages of electric linear actuators include their precision, easy integration with digital control systems, and quiet operation. They also offer cleaner performance, as they don’t require hydraulic fluids or compressed air, reducing the risk of leaks and contamination. However, electric actuators tend to have limited force capacity compared to hydraulic options, making them less suitable for heavy-duty applications. Additionally, they may require more upfront investment and can be sensitive to high temperatures, which may impact their longevity and performance in extreme conditions.

Conclusion

Whether it’s a 7th axis robot transfer unit, gantry robot, lane adjustment for packaging, or any other application, choosing the proper linear actuator is essential. Hopefully this blog has shed some light on the topic, and made the decision-making process simpler.

Frequently asked questions

The main types of linear actuators include:

- Belt-driven: Uses a tensioned belt for linear motion

- Screw-driven: Uses a lead screw or ball screw mechanism

- Rack and pinion: Uses a gear mechanism for linear motion

- Hydraulic: Uses hydraulic fluid pressure for motion

- Pneumatic: Uses compressed air for motion

- Electric: Uses electrical energy for precise motion

Belt-driven linear actuators use a tensioned belt for linear motion. They are particularly suitable for:

- High-speed applications: Excellent for rapid linear movement

- Low-load applications: Best when heavy lifting isn't required

- Long strokes: Ideal where extended travel distances are needed

- Common applications: 7th axis robot transfer units and gantry robots

Screw-driven linear actuators, which use a lead screw or ball screw mechanism, are best for applications requiring:

- High accuracy: Precise positioning and movement control

- Shorter travel distances: Optimal for distances up to about five feet

- Moderate to high loads: Can handle substantial weight while maintaining precision

- Repeatability: Consistent performance over multiple cycles

Rack and pinion linear actuators offer several key advantages:

- Durability: Robust construction for long-lasting performance

- High load capacity: Can handle heavy loads effectively

- Environmental resistance: Operate effectively in various environmental conditions

- Heavy-duty applications: Suitable for demanding industrial environments

- High-temperature tolerance: Can function in extreme temperature conditions

Hydraulic linear actuators use a piston inside a cylinder with an incompressible hydraulic fluid supplied by a pump to generate motion.

Benefits: Ideal for high-force applications with excellent power-to-weight ratio.

Limitations:

- Prone to leaks in the hydraulic system

- Require higher maintenance compared to other types

- Need hydraulic pumps and fluid management systems

- Can be messy if leaks occur

Pneumatic linear actuators use pressurized air instead of hydraulic fluid for motion.

Advantages over hydraulic:

- Simpler design: Less complex than hydraulic systems

- More cost-effective: Lower initial and operating costs

- Cleaner operation: No risk of fluid leaks

- Extreme temperature tolerance: Can operate in very hot or cold conditions

Requirements: Need a compressor to maintain air pressure.

Electric linear actuators convert electrical energy into precise, straight-line motion.

Common applications:

- Robotics and automation

- Medical equipment

- Industrial automation systems

Advantages:

- High precision: Excellent accuracy and repeatability

- Easy integration: Simple connection with digital control systems

- Quiet operation: Low noise levels

- Clean operation: No fluids or compressed air required

Disadvantages:

- Limited force capacity compared to hydraulic options

- Higher upfront cost

- Sensitive to high temperatures

Belt-driven linear actuators are generally best for high-speed applications. Their design allows for rapid linear movement with minimal mechanical resistance, making them ideal for applications requiring quick positioning and high-velocity operations.

They excel in scenarios where speed is prioritized over heavy load capacity, such as pick-and-place operations, rapid positioning systems, and automated assembly lines.

Hydraulic linear actuators are ideal for high-force applications. They can generate tremendous force due to the incompressible nature of hydraulic fluid and the mechanical advantage of the piston-cylinder system.

Common high-force applications include:

- Heavy machinery operation

- Construction equipment

- Press operations

- Large-scale industrial lifting

- Aerospace and marine applications

Electric linear actuators are known for providing the most precise movement control. Their ability to integrate with digital control systems and provide exact positioning makes them the preferred choice for precision applications.

High-precision applications include:

- Medical devices and surgical equipment

- Laboratory instruments

- Semiconductor manufacturing

- Optical equipment positioning

- Quality control and inspection systems

Consider these key factors when selecting a linear actuator:

- Force requirements: How much weight or resistance must be moved?

- Speed requirements: How fast does the motion need to be?

- Precision needs: What level of accuracy is required?

- Stroke length: How far does the actuator need to travel?

- Environmental conditions: Temperature, humidity, contamination

- Power availability: Electrical, hydraulic, or pneumatic power sources

- Maintenance requirements: How much upkeep is acceptable?

- Budget constraints: Initial cost and operating expenses

Maintenance requirements vary by actuator type:

- Electric: Minimal maintenance - mainly cleaning and occasional lubrication

- Pneumatic: Regular air filter replacement and seal inspection

- Hydraulic: Frequent fluid changes, seal replacement, and leak monitoring

- Belt-driven: Belt tension adjustment and replacement

- Screw-driven: Lubrication of screws and periodic inspection

- Rack and pinion: Gear lubrication and wear monitoring

If you still have questions about linear actuators for your application, don’t hesitate to visit our website or contact an igus expert today.