Shaft considerations for bearing applications

When it comes to deciding which shaft/pin solution is best for your application there are a lot of factors to consider; type of steel, machinability, surface and core hardness, surface roughness, availability, price, corrosion protection, retention features, etc. While these aspects are nothing new to the design phase, they are becoming even more important as we move away from traditionally greased bearings to dry running, maintenance free bearings. We will discuss the most important topics for bearing performance: surface hardness, surface roughness, and corrosion resistance. First up, a brief story from the agricultural industry on shaft hardness.

In the field

A few years ago, I was consulting with a customer, an engineer at a manufacturer of tillage equipment, on a field cultivator shank pivot. Loads were slightly higher than average, 5000 psi. per bushing. Initial testing used CD AISI 1045 which has an average surface hardness of 20 HRC.

The three bushings tested were metal-backed, Teflon-lined, and iglide Q. (Q is one of the harder materials we offer) After field testing, it was discovered that both bushings had failed. Upon further inspection, the bushings had actually worn into the shaft. Next, I informed customer that they needed to harden the shaft surface and additional testing garnered much better results.

Let’s dive into some considerations on shaft harness!

Surface hardness

There are two separate hardness factors that come into consideration when designing a pin, core and surface. Both play a part in your application, but surface hardness is the most important. If the surface hardness is too soft (under 30 HRc), a metallic bearing or even a plain bushing with a high Shore D rating can damage the pin, causing premature bearing failure, and requiring pin replacement.

What is the ideal hardness and how do you achieve it?

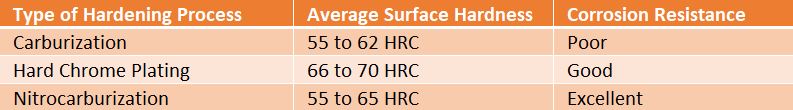

For outdoor applications such as agriculture and construction equipment, where abrasive dirt and contaminants are always present, a surface hardness rating of minimum 50+ HRC is ideal. There are many ways to achieve this, e.g. carburizing (case hardening), hard chrome plating, or nitrocarburization. See table below for comparison.

The biggest drawback of carburizing is the lack of corrosion protection. Hard chrome is a good surface hardening solution and provides good corrosion resistance but requires an extra step in order to provide superior corrosion resistance. However, nitrocarburization provides the best of both, all in the same process. (We will discuss the corrosion resistance component in the third blog)

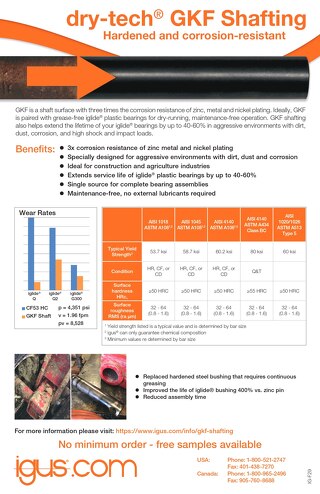

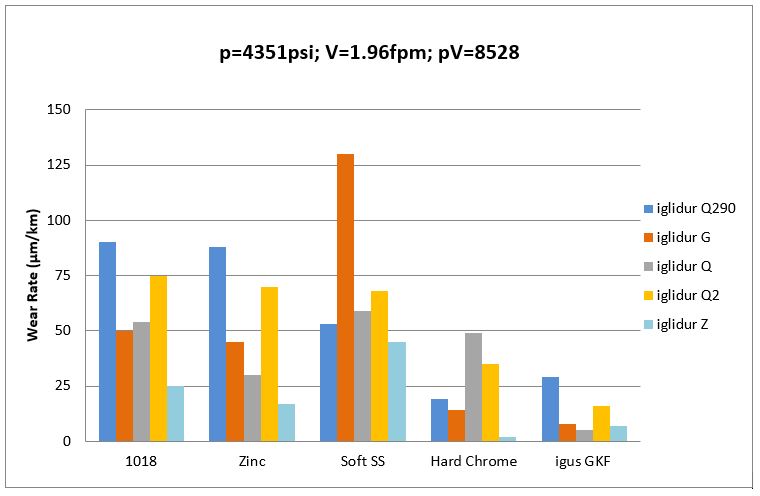

igus® now offers GKF Shafting, which is a version of nitrocarburizing; however, we have optimized the process to provide a superior wear surface for our iglide materials. The table below shows the wear rate of several iglide bushings when mated with various shafting materials and hardness ratings. As you can see with the hard chrome and GKF shafts, the wear rate is significantly lower than the softer alternatives.

Surface roughness of shafting

The roughness of a shaft plays an important part in the life of your application, especially when paired with a self-lubricating bushing. On a microscopic level, a shaft has many peaks and valleys, as seen below.

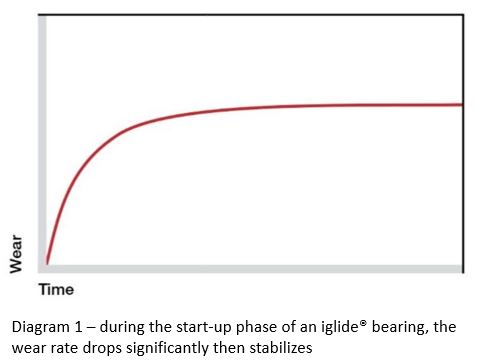

When the shaft and bushing first begin to interact with each other, a transfer of bushing material, and dry lubricants happens. The valleys are “filled” with the transfer material and create an optimized running surface after the initial break-in period, thus reducing the coefficient of friction, and providing a stabilized wear rate for the life of the application (See Diagram 1). To learn more on this subject, check out this video on the science behind the iglide® plastic materials below:

What is the ideal surface roughness?

You might think that a “very smooth” surface is the best option. However, having a surface that is too smooth can be just as harmful as having a surface that is too rough. If the surface is too smooth, the transfer of material is not able to take place and you will see an increase in friction due to adhesion. On the other hand, if the surface is too rough the surface will act like a file and removes too much material and will decrease the life of the bushing. The ideal range for iglide bushings is 16-64 RMS for oscillating or pivoting applications, and 8-16 RMS for linear applications.

Trouble in the field

Years ago, I received a phone call from a long-time customer asking for a visit to review an application. They had been using one of our iglide® bushings successfully in their application for a couple of years, but they were starting to hear complaints about the pivot seizing after the unit was stationary during the offseason. The first comment from the customer was, “your bushing is failing, we need to look at a different material.” In my experience, if we fully understand the application there is almost always some other reason for premature bushing failures. In this case, it was corrosion. The picture below is the shaft from this application after only 2 seasons. My response, “you don’t have a bushing problem, you have a shafting problem!”

Corrosion is a leading cause of failures for bushings. When corrosion begins to form on the surface of the shaft it changes the structure and creates a very poor mating surface. The surface roughness increases, and fine metallic particles begin flaking off. These metallic flakes are very abrasive and will grind away the bushing.

Shaft corrosion: not just red rust

Corrosion presents itself in several ways. While red rust, as shown above is the most visible form, there is another way to tell that corrosion is present. The pictures below are 3 pins that have been used in real world testing. As you can see, there is no visible red rust but there is quite a lot of pitting on the surface. This pitting is the result of metallic particles being flaked off during use. Since the application was in continuous motion the visible red rust has not yet been formed. But as these are left stationary, the visible red rust will surely begin to form.

Why shaft plating and coatings just can't hang on

So how do you protect against corrosion? That’s an age-old question and one that comes with many answers. The most common corrosion inhibitors used in agricultural and construction machinery are zinc, nickel, and chrome plating. Each one of them has their advantages and disadvantages. Zinc and nickel are relatively inexpensive, while chrome provides a hardened surface. However, all 3 have a shared flaw; they are thin layered coatings that can be worn away by a bushing. As soon as you remove the thin layer you are back to bare alloy and corrosion begins to rear its ugly head. As you can see in the picture below, the yellow zinc coating was worn off during use which allowed corrosion to form and completely wearing away the bushing.

igus® has addressed this common design challenge by developing GKF Shafting. When you incorporate GKF into your design you ensure the busing is running on a ideal surface roughness and hardness as well as superior corrosion resistance compared to zinc, nickel, and chrome plating. We have optimized the manufacturing process in order to provide a pin that is ready to be used in a greaseless, maintenance-free pivot.