Understanding Tribo Coatings: Enhancing Performance Through Surface Science

In the world of mechanical systems, friction, wear, and lubrication are constant challenges. Whether it's a high-performance automotive engine or a simple ball bearing in a packaging machine, the efficiency and durability of moving parts are directly influenced by how surfaces interact. This is where tribo coatings come into play.

What Is a Tribo Coating?

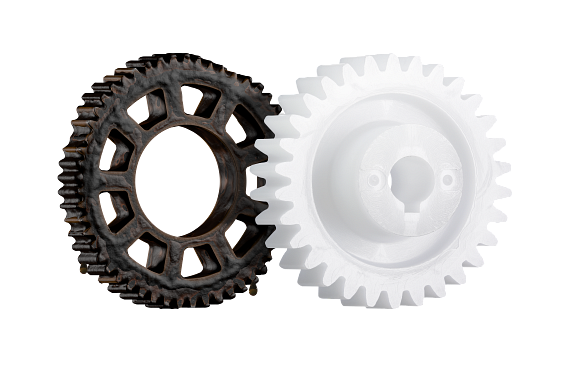

"Tribo" stems from tribology, the science of friction, wear, and lubrication. A tribo coating is a type of surface treatment designed to reduce friction and wear between contacting surfaces in motion. These coatings are typically engineered to provide a smoother, or more lubricious surface, ultimately enhancing the performance and lifespan of mechanical components.

Why Are Tribo Coatings Important?

In systems where metal or other materials are constantly in motion relative to one another, friction leads to:

- Higher maintenance costs and potential failure

- Reduced efficiency and performance

- Material degradation (wear and erosion)

By applying a tribo coating, you can significantly reduce these negative effects. The benefits include:

- Lower friction coefficients

- Improved wear resistance

- Increased durability and reliability of components

- Lower maintenance costs

Other benefits of tribo coating include:

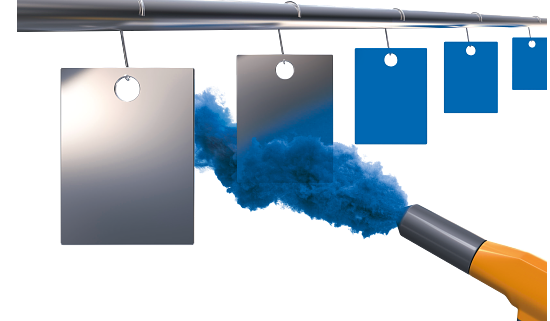

- Ability to coat large surface areas

- Ability to coat complex geometries

- Low profile

- Ability for surfaces to be recoated

Types of Tribo Coatings

There are many types of tribo coatings, tailored to different environments and materials. Some of the most common include:

1. Diamond-Like Carbon (DLC) Coatings

Known for their hardness and low friction, DLC coatings are widely used in automotive, aerospace, and medical applications. They mimic the properties of natural diamond while being more versatile in application.

2. Ceramic-Based Coatings

Materials like titanium nitride (TiN), chromium nitride (CrN), and aluminum titanium nitride (AlTiN) offer excellent wear resistance and thermal stability, making them suitable for cutting tools and high-temperature environments.

3. Solid Lubricant Coatings

These include materials such as molybdenum disulfide (MoS₂) and graphite, which provide lubrication in dry or vacuum conditions—essential for aerospace and space applications.

4. Polymer-Based Coatings

Polymers such as PTFE (Teflon) are used in low-load, low-speed applications due to their excellent non-stick and low-friction properties.

Applications Across Industries

Tribo coatings find applications in a wide range of industries:

- Automotive: Engine components, piston rings, camshafts

- Aerospace: Landing gear, actuators, turbine blades

- Packaging: Chutes, hoppers, conveyors

- Medical Devices: Surgical instruments, implants, prosthetics

- Industrial Manufacturing: Gears, bearings, cutting tools

- Energy: Wind turbine components, drilling equipment

Final Thoughts

Tribo coatings may be invisible to the naked eye, but their impact is substantial. By optimizing surface properties, they reduce friction, cut wear, and extend the life of critical components—making them an essential part of modern engineering solutions.

Whether you're designing a cutting-edge aerospace system or improving the reliability of industrial machinery, understanding and leveraging tribo coatings can offer a competitive edge.