Dry room cable management for lithium-ion battery production

In controlled manufacturing environments where even the slightest presence of moisture can compromise product integrity and safety, dry rooms stand as critical infrastructure. They’re most often found in electronics manufacturing applications such as lithium-ion battery production for electric vehicles.

Learn more about dry rooms, how they function, and components that can be used to improve their design, in this blog.

What is a dry room?

A dry room is a controlled environment designed to maintain extremely low humidity — often less than 1% relative humidity (RH) — and a stable temperature. A standard room will often range from 30–40% humidity. In the same way cleanrooms are designed to minimize particles, dry rooms minimize humidity.

The primary purpose of a low-humidity dry room environment is to allow moisture-sensitive products like lithium-ion batteries, other electronics, and pharmaceuticals to be manufactured without the risk of product degradation.

Key components & specifications

There are numerous different components that allow dry rooms to achieve such a low relative humidity. These include dehumidification systems, airlocks, seals, and more.

- Dehumidification systems: Industrial desiccants and adsorption units remove moisture from the air, allowing for sub-1% RH levels.

- Airlocks: Airlocks are used to prevent humidity ingress during personnel or material entry.

- Seals: The entire room utilizes vapor barriers and airtight seals to block all external air from entering the room.

- Real-time monitoring: Sensor systems continuously monitor humidity levels and temperature within the room, and a central control system makes adjustments as needed.

The importance of low humidity in dry rooms

As important as it is to know dry rooms require low humidity, it’s equally important to understand why. There are two major reasons for this: product quality and safety.

- Product quality: During manufacture, there’s a risk of electrochemical reactions within the battery if exposed to too much moisture. This can degrade internal components of the battery, reducing lifespan, storage capacity, and overall performance.

- Safety: The same reactions that can reduce battery performance can also lead to major safety issues such as thermal runaway and fire. This poses a risk both to production equipment and any workers in the vicinity.

Plastic cable management solutions for dry rooms

Many dry rooms utilize robotic cells to manufacture lithium-ion batteries for hybrid and electric cars. With any robotic system, proper cable management is essential for efficient and reliable operation.

Most cable management solutions made of plastic cannot operate in the low humidity found in dry rooms, severely limiting the available options. However, igus® offers triflex® cable management solutions made from ESD material that can perform reliably in dry room environments.

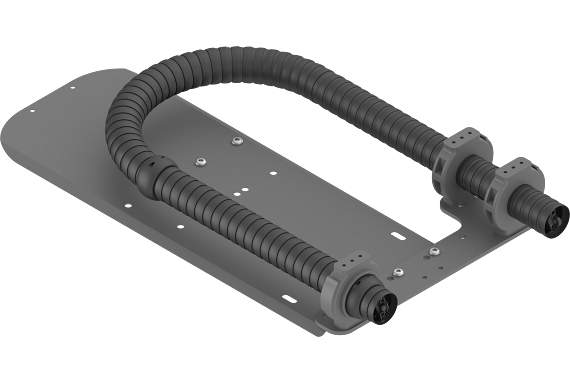

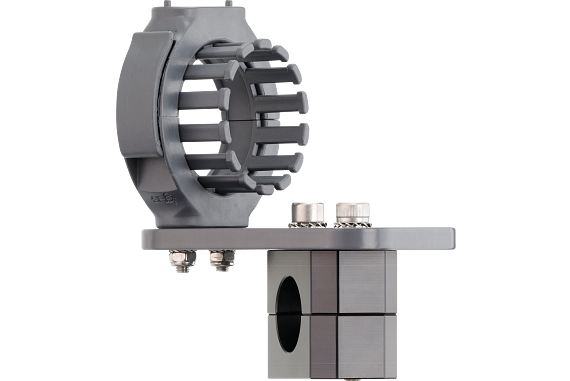

triflex ESD cable carriers can be paired with mounting brackets and retraction systems — both designed to withstand dry room operation — to more safely and efficiently guide the cable carrier and prevent loop formation.

Like all triflex cable carriers, our ESD variants utilize a ball-and-socket design that improves tensile strength and makes lengthening or shortening the carrier quick and easy.

ESD triflex systems have already been successfully implemented in dry room applications, with one major automotive manufacturer relying upon them for EV battery production.

Conclusion

Given the critical need to control moisture in the manufacturing of sensitive products, dry rooms are indispensable environments equipped with sophisticated dehumidification, sealing, and monitoring systems.

While the extreme conditions within dry rooms can pose challenges for standard components, specialized solutions like igus' ESD triflex cable management systems demonstrate that reliable and efficient operation is achievable.

As industries reliant on moisture-sensitive manufacturing continue to advance, the importance of robust and compatible components within these ultra-dry environments will only continue to grow.