Tensile strength: what is it and how do you calculate it?

Tensile strength is a critical material property that is essential to the success and safety of countless industrial applications. From the construction of towering skyscrapers to the intricate design of robotics components, understanding tensile strength is essential for engineers, manufacturers, and material scientists. This blog post will delve into the concept of tensile strength, its importance, and the methods used to calculate it.

What is tensile strength?

Tensile strength is the maximum amount of stress a material can withstand while being pulled or stretched before breaking. Ultimately, this makes tensile strength a measure of a material’s resistance to being pulled apart. This is crucial in determining whether a material is suitable for an application with tension forces.

Types of tensile strength

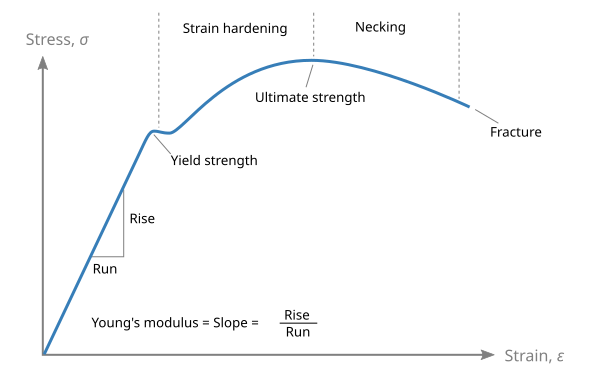

There are two key “types” of tensile strength to understand: yield strength and ultimate strength.

Yield strength is the greatest amount of stress a material can withstand without being permanently deformed or damaged.

Ultimate strength is the amount of stress necessary for a material to become permanently deformed or damaged, and is what tensile strength calculations solve for.

How to calculate tensile strength

Calculating tensile strength is a simple three-step process:

- Tensile Testing: The most common method is to perform a tensile test using a universal testing machine.

- Force Measurement: During the test, the force applied to the material is measured until it breaks.

- Calculation: Tensile strength is then calculated using the following formula: Tensile Strength = Force (N) / Cross-Sectional Area (m2)

Tensile strength calculator

Try out our tensile strength calculator below!

Tensile Strength Calculator

External factors that impact tensile strength

There are a number of factors that can impact a material’s tensile strength. These include environmental factors like temperature or humidity, application-specific factors like loading rate, and even the manufacturing process used.

- Temperature: Many materials will lose some of their strength at high temperatures, reducing their tensile strength. It’s vital to account for the temperature within an application and test accordingly.

- Humidity: Presenting a problem primarily in polymers, moisture absorption can lead to a reduction in tensile strength due to softening of the material.

- Loading rate: Applications with dynamic impact loads will experience a higher loading rate, which can impact tensile strength. This is often beneficial, especially for certain steels that actually have an increased tensile strength when facing high loading rates.

- Manufacturing process: Certain manufacturing processes like cold working, heat treatment, and alloying can be used to increase tensile strength.

Tensile strength of select igus plastics

Below are tensile strength values for some of the most popular iglide® plastics available from igus®.

| Material | Tensile strength at 68°F | Test method |

|---|---|---|

| iglide® J | 73.0 MPa | DIN 53452 |

| iglide® R | 70.0 MPa | DIN 53452 |

| iglide® A181 | 48.0 MPa | DIN 53452 |

| iglide® TX1 | 55.0 MPa | DIN 53452 |

| iglide® Z | 95.0 MPa | DIN 53452 |

Conclusion

Understanding tensile strength is fundamental in engineering and manufacturing. It ensures that materials can withstand the forces applied to them, guaranteeing the safety, durability, and performance of products and structures. By considering the types of tensile strength, calculation methods, and influencing factors, professionals can make informed decisions in material selection and application.