How fast can lead screws really go?

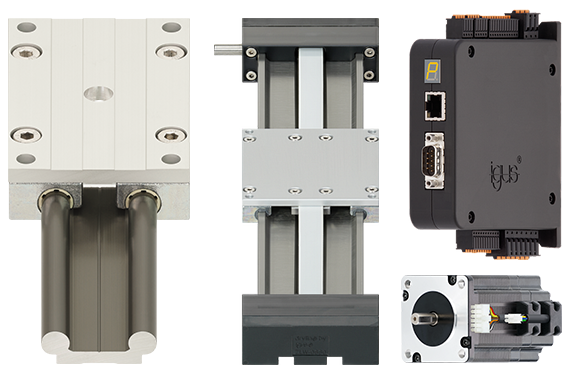

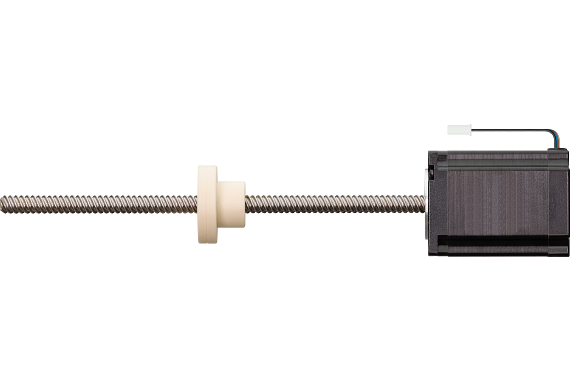

When you’re designing a linear motion system, the lead screw is often a fundamental component. One of the most critical factors when choosing a lead screw is its speed capability. The speed at which a lead screw can operate significantly impacts the overall effectiveness and service life of the entire mechanism.

Understanding “slow” in context

It’s crucial to establish a proper frame of reference for lead screw speed. What might be considered slow in applications using belt drives or hydraulic systems isn’t necessarily slow for a lead screw. Lead screws have unique characteristics that dictate their optimal speed ranges.

The 200RPM rule of thumb

A good rule of thumb for optimal lead screw performance is to limit their operation to a maximum speed of 200 RPM (rotations per minute). Staying within this range helps ensure smooth operation, minimal wear, and consistent accuracy.

Pushing the limits: when you need more speed

While 200 RPM is a good starting point, it’s possible to far exceed this limit. However, doing so requires a much more detailed and careful approach. Successfully operating a lead screw at higher speeds involves a complex mix of different factors:

- Screw dimensions: The diameter and length of the screw are critical. Thicker screws are typically more stable at higher speeds and less prone to whipping.

- Geometry: The design of the screw threads (e.g. the thread profile) can influence friction and heat generation.

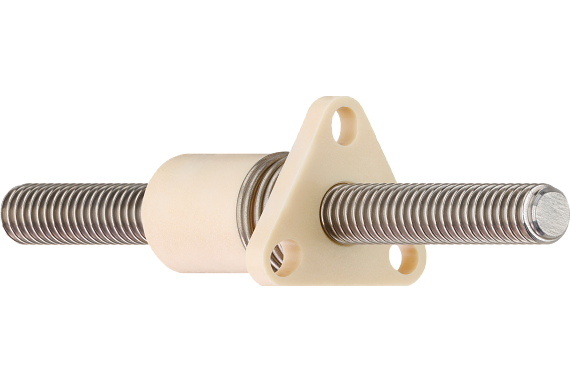

- Proper installation: Precise alignment, adequate support, and appropriate preloading are essential to minimize vibrations and ensure smooth operation at elevated speeds.

Related: How to properly secure a lead screw

Friction and heat

The primary limiting factor for lead screw speed is friction. As the rotational speed and the axial load (the force pushing on the screw) increase, friction increases and generates heat. This heat buildup has negative consequences such as:

- Increased wear: Higher temperatures accelerate the wear between the screw and nut, reducing total service life of the components.

- Reduced accuracy: Heat can cause thermal expansion, which can affect the precision of the system.

Noise and vibration

Another significant speed-related issue in lead screw applications is noise and vibration. Depending on the screw’s diameter and length, even steel screws can exhibit a phenomenon known as whipping at high RPMs.

Whipping is a dynamic instability where the screw begins to oscillate or vibrate in a circular motion, resulting in a very loud and unpleasant noise. Vibrations from whipping can also reduce the accuracy of the system.

Achieving speed through design

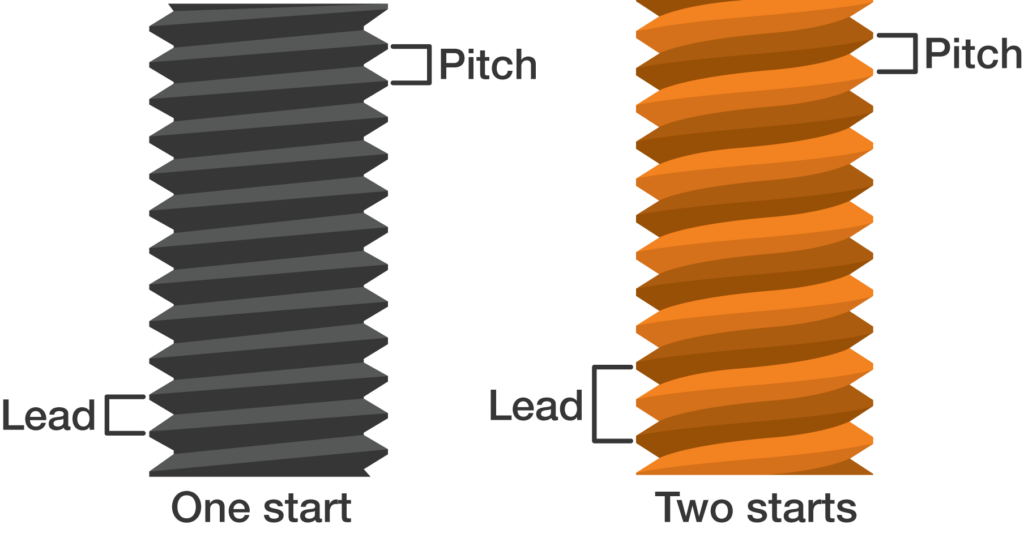

Fortunately, there are strategies to achieve higher linear speeds without solely relying on increasing the screw’s RPM. The key is the screw’s lead. Lead is the linear distance the nut travels for each complete rotation of the screw.

Blog: What is screw pitch, and how is it different from lead?

Lead screws are available with a wide variety of leads. Lead screws from igus have leads ranging from 1mm all the way to 100mm (approximately 4 inches). Keeping in mind the 200 RPM rule, the max feed rate of a 1mm is about 3mm per second. For a screw with a 100mm lead, the max feed rate is 300mm — just under a foot — per second.

Conclusion

By carefully selecting the appropriate lead, engineers can optimize the linear speed of a lead screw system without necessarily pushing RPM to levels that can cause excessive friction, heat, noise, or vibration.