How to properly secure a lead screw in your design

One of the most common errors engineers make when designing a lead screw system is improperly securing the ends of the screw. This blog will explain the three primary ways a lead screw can be secured — free, loose, and fixed — and when it is ideal to use each.

The three categories of lead screw securing

Unsecured

An unsecured lead screw is exactly what it sounds like—a screw that has no securing whatsoever. This method is almost never advisable and should be avoided if possible. The reason? As the screw rotates, an unsecured end will cause even the sturdiest and slowest moving of screws to whip.

This whipping can lead to extreme noise and a rapid decrease in the lifespan of the lead screw system. The uncontrolled movement introduces vibrations and stresses that the screw and its components aren't designed to handle, leading to premature wear and potential failure.

Loose securing

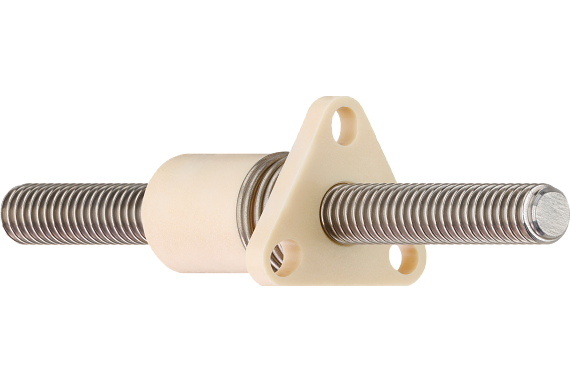

A loose securing method involves securing the screw with something like a bushing. While this configuration does constrain the screw, the clearance between the bushing and the screw can cause whipping, especially in faster applications.

igus recommends that loose securing of a lead screw should be reserved for slow, hand-driven applications. In these scenarios, the lower speeds and forces minimize the adverse effects of the clearance. However, it’s important to recognize that even in hand-driven applications, a loose support might not be the ideal long-term solution if precision and longevity are critical.

Fixed securing

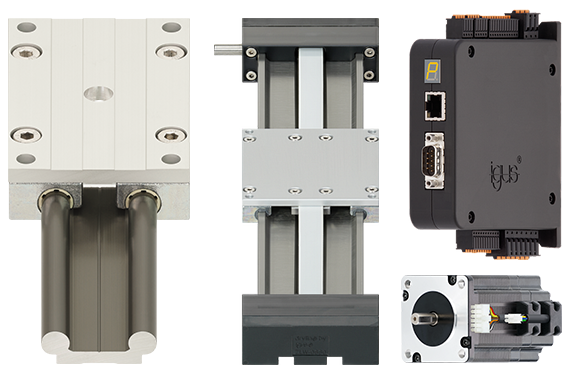

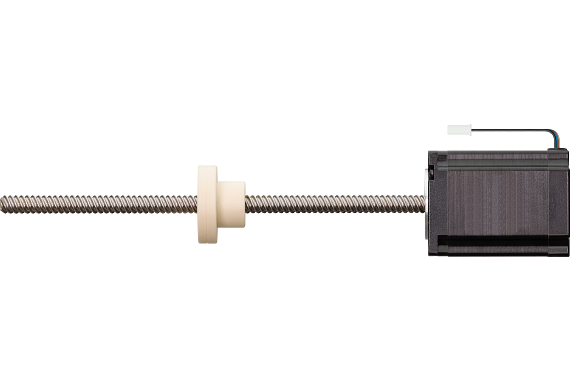

Fixed securing is when a lead screw is constrained with ball bearings and clamps. This configuration has little to no clearance and is optimal for all lead screw applications. It’s required for motorized applications to ensure proper function.

Ball bearings provide precise support, minimizing runout and deflection, while clamps hold the bearings securely in place. This robust method maintains the screw's alignment and stability, even under high speeds and loads.

Key considerations for securing lead screws

- Clearance: The less clearance you have in the end supports of the screw, the better. Excessive clearance allows for unwanted movement, contributing to vibration, noise, and wear.

- Account for misalignment: If the system needs to float to account for misalignment, it should be added in the linear guides or nut support. Designing float into these components allows the system to accommodate slight deviations without putting undue stress on the screw.

- Free end solutions: If you can’t avoid having a free end in your application, try increasing the diameter, shortening the length, or reducing the RPM of the screw to mitigate the effects of whipping and give yourself the best chance of avoiding issues.

- Loose support in motorized applications: If a loose support is used in a motorized application, noise may not always be an issue depending on speed. However, the life cycle of the system will be reduced.

By carefully considering these principles and choosing the appropriate method of securing lead screws, engineers can design more effective, efficient, and reliable linear systems. Proper lead screw securing is not just a detail; it's a fundamental aspect of ensuring optimal performance and longevity in linear motion applications.