AGV vs AMR: which robot is right for your business?

Automation has become a key driver of efficiency and productivity, regardless of industry. Among the most popular automation solutions are automated guided vehicles (AGVs) and autonomous mobile robots (AMRs).

While both technologies automate and enhance material handling and reduce manual labor, there are key differences in their functionality, flexibility, and areas of application that set them apart.

Related: Automated material handling, explained

This blog explores these differences, highlights similarities, and provides insights into their applications and components.

What are AGVs and AMRs?

Automated Guided Vehicles

AGVs are material transport vehicles that follow predefined paths using guidance technologies such as magnetic strips, laser navigation, or embedded wires.

These vehicles operate within structured environments like warehouses and manufacturing plants, ensuring predictable and repeatable movements.

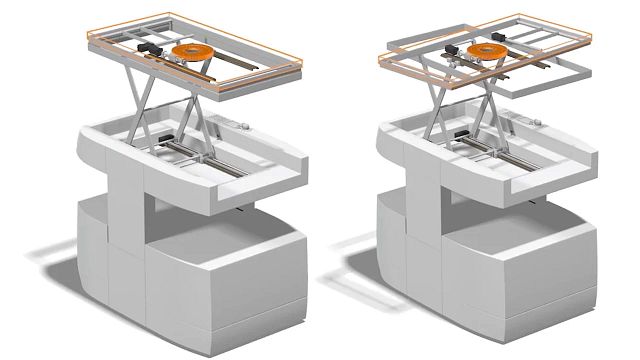

Autonomous Mobile Robots

AMRs, on the other hand, use advanced sensor technologies such as LiDAR, cameras, and artificial intelligence (AI) to navigate dynamically.

Unlike AGVs, AMRs do not require predefined paths and can adapt to their surroundings, making them ideal for unpredictable environments.

Key differences between AGVs and AMRs

| Feature | AGVs | AMRs |

|---|---|---|

| Navigation | Follows predefined paths | Uses AI-based, real-time navigation |

| Flexibility | Limited to structured environments | Adapts to dynamic environments |

| Sensors & Guidance | Magnetic strips, laser guidance | LiDAR, cameras, machine learning |

| Obstacle Avoidance | Stops and waits until obstacle is cleared from path | Detects and maneuvers around obstacles |

| Setup Requirements | Requires installation of guidance infrastructure | Minimal setup, adapts to surroundings |

| Cost & Scalability | Lower initial cost, but expensive to modify | Higher initial cost, but more scalable |

| Applications | Best for repetitive, consistent material deliveries | Ideal for dynamic environments |

Applications of AGVs vs. AMRs

Common AGV applications

- Automotive manufacturing: Transporting vehicle components between assembly stations

- Warehouse logistics: Moving pallets along fixed paths for inventory management

- Heavy-duty industrial transport: Handling large loads in structured environments

Common AMR applications

- Healthcare: Delivery of medication and medical supplies, and UV disinfection

- Hospitality: Delivering products, food, or other supplies to guests and customers

- Manufacturing: Transporting complex materials through dynamic warehouses

High-performance plastic components for AGVs and AMRs

The selection of quality components for AGVs and AMRs is equally as important as the task they’re designed to fulfill. While metal components may seem like the easy choice, high-performance plastic components actually offer numerous benefits over their metal counterparts:

- Self-lubricating: No need to manually relubricate parts, saving time and money

- Resists dirt & dust: A lack of grease means there’s nothing for dirt and dust to adhere to

- Wear-resistant: Built-in reinforcing fibers resist wear and extend part lifetime

- Lightweight: Plastic components are lighter than metal, extending total battery life

- FDA compliance: FDA-compliant materials can be used in food contact applications

Further reading: Improve your autonomous mobile robots with plastic components

Choosing between AGVs and AMRs

The choice between an AGV and AMR should be simple after reading this blog. The operational environment plays a crucial role, as AGVs are best suited for structured spaces, whereas AMRs excel in dynamic settings.

Cost and scalability are also important considerations; AGVs typically have lower upfront costs but require infrastructure modifications, while AMRs offer greater flexibility at a higher price.

Additionally, implementation time differs between the two, with AGVs requiring setup with guidance systems, whereas AMRs can be deployed with minimal adjustments.

Conclusion

AGVs and AMRs both play crucial roles in industrial automation, but their differences in navigation, flexibility, and applications determine their suitability for different environments. While AGVs excel in structured, predictable workflows, AMRs offer superior adaptability for dynamic and evolving operations.

Choosing the right solution depends on operational needs, cost considerations, and future scalability. As automation technology advances, both AGVs and AMRs will continue to shape the future of material handling and logistics.