What is a cobot?

Collaborative robots, commonly referred to as cobots, are a groundbreaking category of robot specifically designed to work alongside humans in shared environments. Unlike traditional industrial robots that operate independently or require safety barriers, cobots are built to interact with people safely and efficiently.

Read on for an in-depth examination of cobots, including their history, advantages over typical industrial robots, and new advancements defining the future of cobot technology.

Defining cobots

As already mentioned, cobots are a specific type of robot engineered to work alongside and assist humans in performing tasks. These can range from repetitive actions to high-precision operations.

Cobots are equipped with sensors, cameras, and advanced software to ensure safety, flexibility, and adaptability in various environments. For example, a cobot in a factory setting might work alongside a human employee on an assembly line, handling repetitive tasks like screwdriving or welding.

Comparing cobots vs. robots

Cobots and industrial robots both serve many of the same general functions, but have key differences that set the two apart. These include collaborative ability, safety features, and ease of use.

Collaboration: Cobots are designed specifically for direct interaction and collaboration with humans. Traditional industrial robots are typically isolated from any human workers for safety reasons.

Safety features: The safety features found in cobots are arguably the most important differentiating factor between cobots and robots. These features include force-limiting technology, making them safe to use without protective cages.

Ease of use: Many cobots feature intuitive programming interfaces which make it simple to program without the need for extensive coding knowledge. Industrial robots often don’t feature these same interfaces, requiring a high level of expertise to successfully program.

The evolution of cobots

The first cobot was developed in 1996 by Michael Peshkin and Edward Colgate, two mechanical engineering professors at Northwestern University. The cobots were designed to be used by General Motors on their assembly lines.

This initial design was simple compared to modern cobots, but served the same basic function of working alongside humans to make otherwise difficult tasks simpler and more efficient.

Recent advancements in technology like sensors, artificial intelligence, and machine learning have since transformed cobots into highly sophisticated tools capable of handling complex tasks. Cobots are also more accessible now than ever, with affordable cobots making it possible for even small and medium-sized businesses to adopt advanced automation solutions.

Core characteristics of cobots

- Human-centric design: Cobots are specifically tailored to complement human capabilities and work alongside humans rather than replace them.

- Flexibility: Cobots can adapt to various tasks and environments, making them suitable for all sorts of industries, ranging from manufacturing and logistics to agriculture and healthcare.

- Affordability: Compared to traditional robots, cobots are often more affordable up-front and offer quicker setup, allowing for a faster return on investment.

What makes cobots unique?

Collaborative robots stand apart from traditional industrial robots due to their ability to safely work alongside humans, adapt to dynamic environments, and handle diverse tasks. Below are a few key characteristics that define cobots and explain why they’re revolutionizing the robotics field.

Designed for human collaboration

Cobots, at their core, are designed for collaboration with humans. Technologies like advanced sensors and force limiters have made it possible for cobots to work safely alongside humans, as they enable cobots to pause operation if humans enter their workspace or come into contact with them.

Flexibility and adaptability

Due to simple and intuitive programming interfaces, cobots can be easily repurposed for various tasks as the need arises. A cobot initially used for welding can be reprogrammed to handle assembly or palletizing tasks, for example. The lightweight and portable design of cobots also makes moving them to various workspaces an easy task.

Compact design

Cobots are typically smaller and more compact than traditional robots, making them suitable for environments with limited space that other robots couldn’t fit into. The lightweight design of cobots also enables easy installation without requiring significant infrastructure changes. This is most relevant for small-to-medium enterprises (SMEs) with constrained workspaces.

Precision and consistency

Collaborative robots are engineered to deliver high levels of accuracy and repeatability, ensuring consistent results across tasks. The advanced sensors and cameras they’re often equipped with allow them to perform intricate operations like handling fragile materials or assembling micro components. Microelectronics soldering is one key area where this is relevant.

Cost-effectiveness

In general, cobots are more affordable than traditional industrial robots, with lower upfront costs and less of a need for extensive safety equipment. This, combined with their ability to handle time-consuming repetitive tasks, leads to a faster ROI regardless of the size of the operation.

Minimal downtime for deployment

The simplified programming and plug-and-play capabilities of cobots allows them to be deployed in a matter of days, or even hours. Alternatively, standard industrial robots can take weeks or even months to fully set up.

Integration with emerging technologies

Cobots are often integrated with AI, machine learning, and the Internet of Things (IoT), enabling smarter operations and better adaptability to complex tasks. Early integration with these technologies will add even more long-term value as they continue to improve and gain additional functionality.

Benefits of cobots

Cobots offer numerous advantages that make them an attractive option for businesses across industries. Outside of the most obvious advantages, such as increased safety and reduced costs, there are a few additional benefits cobots provide, discussed below.

Employee empowerment

By taking over repetitive or physically demanding tasks, cobots reduce worker fatigue and risk of injury. This also allows workers to take on roles that require creativity, problem-solving and decision-making, leading to higher job satisfaction.

Scalability for businesses

Cobots allow businesses to scale operations efficiently by increasing production capacity without raising labor costs significantly. This is particularly beneficial for SMEs that need to respond to market demands quickly.

Sustainability

Cobots contribute to sustainability efforts by optimizing resource use and reducing waste. Their energy-efficient operation aligns with green manufacturing practices, helping businesses meet environmental goals.

Key applications of cobots

Collaborative robots (cobots) are transforming industries by providing efficient, safe, and adaptable solutions for a wide range of tasks. Below are some of the most common and impactful applications of cobots across various sectors.

Manufacturing & logistics

Cobots can be found all across the manufacturing industry, from applications like assembly and quality control to packaging and palletizing. Companies like Ford are already successfully implementing cobots into their assembly lines. This has helped reduce stress on employees and improve the production efficiency.

Cobots are quickly becoming a staple in logistics as well, with inventory management, material handling, order picking, and labeling emerging as some of the most popular applications. In each of these areas, cobots increase efficiency and make workflows safer for human workers.

Healthcare

In the healthcare industry cobots can be used primarily for assistance during minimally invasive surgical procedures, or as a personal healthcare assistant.

In surgery, cobots can simply help with holding tools steady, or even assist with high-precision movements. A cobot can perform these movements with more precision than even the most skilled surgeons, making the surgery less invasive and improving patient outcomes.

Cobots can also be used for more repetitive healthcare tasks like pipetting, mixing, and sorting in lab settings. This allows researchers to focus on analysis and other high-level tasks, while increasing the efficiency and reliability of lab workflows.

Agriculture

Cobots can be involved all throughout agricultural processes, from planting and seeding crops to monitoring and harvesting. They can plant seeds with precision and monitor soil and weather conditions to ensure optimal growth. Finally, cobots can be used to harvest plants. This is particularly helpful with delicate crops like strawberries or tomatoes.

Education

In the field of education, cobots are an excellent tool for teaching various aspects of robotics, programming, and automation. The user-friendly interfaces and flexibility of cobots makes them more effective than robotic arms or other industrial robots. Their affordability also makes them more attractive to schools or universities operating on a limited budget.

Challenges and misconceptions about cobots

Challenges

- Initial investment: While typically more affordable than many industrial robots, the initial cost of acquisition and integration of cobots can be a hurdle for smaller businesses.

- Training & development: Proper use of cobots requires at least some level of technical expertise, which means adequate training for all operators. This is most important during initial setup and integration.

- Integration with existing systems: The integration of a cobot into existing workflows needs to be seamless. This can pose a challenge in environments using outdated machinery or rigid processes.

- Industry-specific challenges: Industries such as food processing and healthcare have strict regulatory standards that cobots must meet before they’re able to be deployed.

Misconceptions

- Cobots will replace human jobs: This is the biggest misconception surrounding cobots currently. However, cobots are designed to work alongside humans and aid them in tasks, rather than replace them completely.

- Cobots are only feasible for large businesses: It’s often believed only large companies with extensive budgets can afford cobots. In reality, many cobots — including the ReBeL cobot from igus — are designed to be affordable for businesses of all sizes through plug-and-play functionality and low upfront costs.

- Cobots lack precision and capability: Compared to traditional industrial robots, cobots are assumed to be a less accurate and less powerful alternative. Advances in cobot technology have rendered these assumptions false, with cobots rivaling traditional robots in both accuracy and capability.

Choosing the right cobot for your needs

Selecting the right collaborative robot is crucial for maximizing its benefits and ensuring a smooth integration into your operations. With the growing variety of cobots on the market, here are the key factors to consider when making your choice.

Define your requirements

Every application will have a different set of requirements and unique factors to prioritize when choosing a cobot. For example, a cobot for assembly may prioritize precision, while one for logistics would prioritize high payload. Understanding your application and its unique requirements is essential when choosing a cobot.

The cobot’s workspace will also impact the selection process. Space constraints, exposure to dust or moisture, and ambient temperature will all need to be accounted for ahead of time.

Payload & reach

Payload and reach are two of the most important specifications for a cobot. It’s essential to choose a cobot that can meet the payload and reach requirements of your application to ensure optimal performance and avoid premature wear or failure.

Programming & ease of use

Most modern cobots are designed with user-friendly operation in mind, but the extent of this will vary between models and manufacturers. Some key features to be aware of are intuitive programming interfaces, compatibility with existing software and systems, and no-code or low-code support.

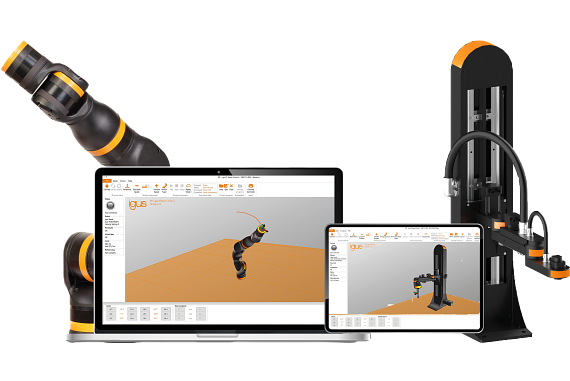

Related: Free igus Robot Control (iRC) Software

Safety features

Cobots are designed for safe operation alongside humans, but specific safety features can vary. Some key considerations should include built-in force and collision detection, compliance with international safety standards such as ISO 10218-1, and adjustable speed and sensitivity settings.

Total cost of ownership (TCO)

Costs associated with cobots extend beyond the initial purchase and integration. Maintenance, spare parts, and downtime should all be included in any TCO analysis, along with the expected ROI from improved efficiency.

The future of cobots

Emerging trends in cobot technology

- Artificial intelligence (AI) integration: AI-powered cobots are capable of making smarter decisions and adapting to changing circumstances. Integrated AI can enable advanced machine vision systems and allow a cobot to perform visual tasks like quality inspection and obstacle detection.

- Enhanced machine learning (ML) capabilities: Similarly to AI, the rise of machine learning enables cobots to learn over time and optimize processes based on previous data. Operations with large amounts of gathered data — such as a smart factory with extensive internet of things (IoT) integration — would see the most benefit from cobots with integrated ML.

Blog: Integrating predictive maintenance with machine learning

- Advanced human-robot collaboration: The most important element of cobots — human interaction — will continue to improve over time. Developments in sensors, interfaces, and more will enable seamless collaboration between human and cobot. Other features like voice recognition and gesture control will bring this collaboration to new heights.

Growing market demand & industry projections

The global market for cobots has been steadily growing over the past decade, and was estimated at USD 2.14 billion in 2024. This market is projected to be valued between USD 7.3 billion and 11.64 billion by 2030.

In 2024, cobots had the largest presence in the automotive, furniture, and food and beverage industries, and the Asia Pacific market had the largest share of cobot revenue. These trends are expected to continue throughout the second half of the decade.

New cobot applications

While the “standard” cobot applications in the automotive, food, or manufacturing industries are the most well known, new applications in non-traditional areas are gaining traction. Fields like education, entertainment, hospitality, and even cleanrooms all hold huge potential for cobots, and are poised to become some of the most well-known areas of cobot application in the near future.

Conclusion

The future of automation is bright, in large part due to the growing presence and capabilities of cobots across all industries. Companies looking to stay ahead of the curve should make an active effort to not only learn more about cobots, but to begin implementing them in processes and exploring the potential they offer.