Integrating predictive maintenance with machine learning

Predictive maintenance is an essential technology in industrial automation that helps prevent unplanned downtime. However, with the recent AI boom, machine learning has emerged as a way to further improve predictive maintenance and optimize machine work cycles. Read on to discover the potential of pairing predictive maintenance with machine learning.

What is predictive maintenance?

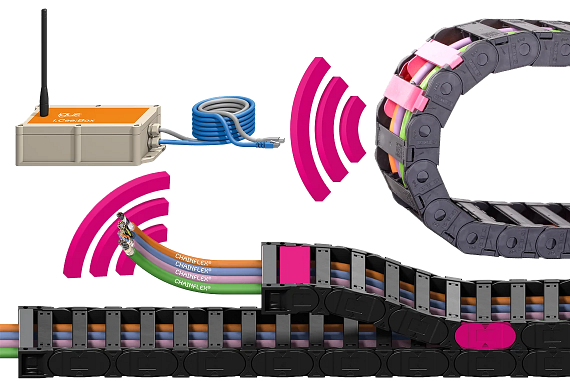

Predictive maintenance is one type of maintenance schedule that predicts when a machine will require maintenance based on specific performance parameters. It’s part of the Industrial Internet of Things (IIoT), operating through the use of sensors which collect a wide range of performance metrics from connected machines. This data collection is known as condition monitoring.

The primary goal of predictive maintenance is to predict machine failure before it occurs, so maintenance periods can be planned in advance. This differs from the other primary IIoT maintenance method, preventive maintenance, though the end goal is the same.

Related: Predictive Maintenance vs. Preventive Maintenance

Did you know? Predictive maintenance can reduce maintenance costs by 25-30% and eliminate breakdowns by 70-75% on average. (Source: U.S. Department of Energy)

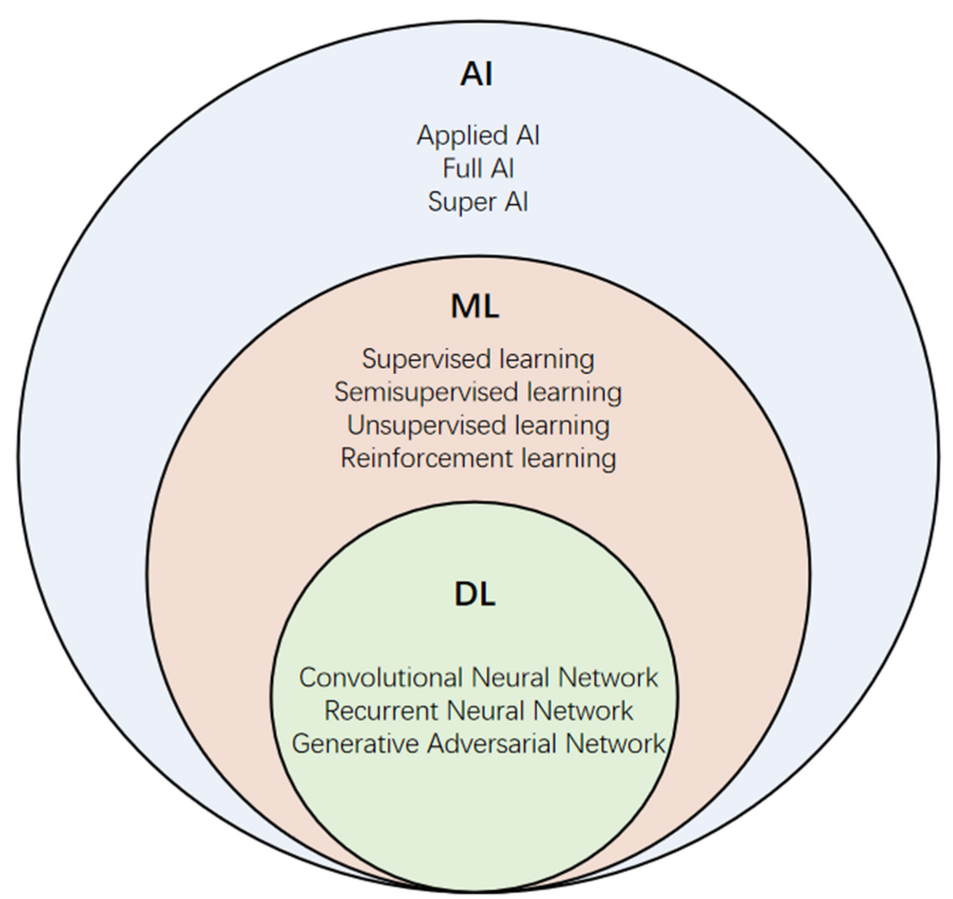

Understanding machine learning

At its core, machine learning uses algorithms to mimic the way humans learn and make decisions. This is done with advanced algorithms that process and analyze large datasets to continuously improve over time.

UC Berkeley breaks down a typical machine learning algorithm into three key components:

A decision process: The algorithm attempts to determine the pattern based on the provided data set.

An error function: The determined pattern is analyzed and compared to “known” examples to evaluate how accurate the determination was.

An optimization process: The algorithm reviews the information from the error function, and adjusts the decision making process to generate more accurate determinations in future iterations.

Types of machine learning models

There are four major types of machine learning model, each with individual strengths suited to various data sets and requirements. These are supervised learning, unsupervised learning, semi-supervised learning, and reinforcement learning.

Supervised learning: Uses a dataset that’s been pre-labeled by humans. The algorithm uses this dataset to determine the accuracy of its own predictions.

Example in predictive maintenance: Predicting equipment failure based on historical failure data.

Unsupervised learning: Uses an unlabeled dataset with no specific desired outcome or answer. The learning model attempts to find structure through methods such as clustering, anomaly detection, or association.

Example in predictive maintenance: Detecting anomalies in sensor readings without predefined failure patterns.

Semi-supervised learning: A combination of supervised and unsupervised learning, semi-supervised learning uses both labeled and unlabeled data. This makes it easier for the model to distinguish difficult data features, while minimizing the amount of manual labor needed to label a full dataset.

Example in predictive maintenance: Identifying potential failure modes with limited labeled failure data.

Reinforcement learning: An iterative process in which the learning model attempts to find the optimal way to achieve a specific goal or maximize performance. The model uses both previous feedback and entirely new tactics to home in on the ideal strategy.

Example in predictive maintenance: Optimizing maintenance schedules based on cost and downtime trade-offs.

Integration of predictive maintenance and machine learning

Predictive maintenance already makes use of advanced algorithms and data analytics to predict how long a machine can continue to run before maintenance is needed. However, these algorithms are static and therefore aren’t as efficient as more advanced dynamic models.

However, with the integration of advanced machine learning these algorithms can improve over time:

- Supervised learning models can take existing performance data and determine performance metrics and patterns that suggest machine failure is imminent.

- Unsupervised models can take the vast amounts of data gathered through sensors and identify values outside of a normal range, alerting operators to potential failure.

- Through reinforcement learning, models can iterate on maintenance schedules based on operator feedback.

By combining the above methods, companies can achieve optimal maintenance schedules that eliminate unplanned downtime and ensure peak efficiency.

Benefits of integration

There are a number of benefits to bringing together machine learning and predictive maintenance. Below are a few of the most impactful.

Improved accuracy: The ability of a machine learning algorithm to adapt and improve over time allows it to become much more accurate than a standard algorithm, which may be affected by the preconceptions of those creating the algorithm.

Cost savings: Because of the improved accuracy explained above, machine learning algorithms can fully optimize maintenance schedules, minimizing necessary downtime and by extension minimizing the costs associated with maintenance and unplanned downtime.

Extended equipment lifespan: Through proper maintenance and avoidance of equipment failure and damage, the service life of equipment can be vastly improved.

Enhanced safety: With potential equipment failures being caught before they occur, employee safety can be improved, as the risk of employees being present when equipment fails is eliminated entirely.

Implementation considerations

As effective as machine learning can be in improving predictive maintenance, there are important considerations to keep in mind to ensure a successful implementation.

Data quality and quantity: Any machine learning model needs a significant amount of high quality data to be effective. Before implementing machine learning, ensure there are various data types (sensor data, failure data, environmental data, etc.) being captured across the entire process for the most accurate results.

Integration with existing systems: If you already have an existing maintenance system established, integrating a machine learning-based predictive maintenance system can prove challenging. This is especially true of older equipment that may require sensor retrofitting and the use of IIoT gateways to gather necessary data.

Contact an expert for integration assistance

Expertise and training: Having skilled personnel to develop, implement, and maintain machine learning models is essential to finding success, whether creating a new solution from scratch or using an off-the-shelf solution.

Implementation readiness checklist

Before implementing machine learning in your predictive maintenance processes, ensure you have:

- Comprehensive sensor network in place

- Robust data collection and storage system

- Clear understanding of critical failure modes

- Skilled data science team or partnership

- Management buy-in for long-term investment

- Plan for continuous model updating and improvement

Affordable solutions for condition monitoring and predictive maintenance

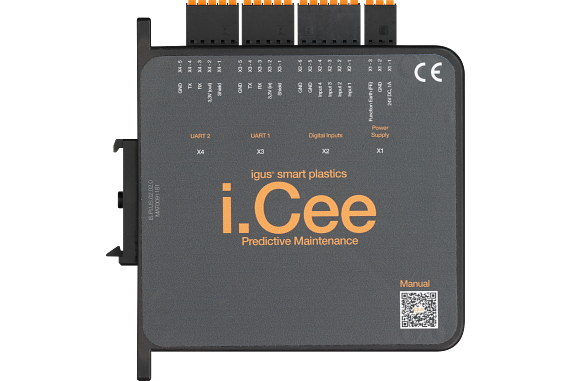

If you’re not sure where to get started with predictive maintenance and machine learning, igus® is the perfect place to kick off your search. igus blends IIoT technology into standard product offerings like cables, cable carriers, and bearings — creating what is known as the smart plastics product line — to provide the highest level of confidence in the condition of these components.

igus’ predictive maintenance technology — called i.Cee — is easy to use and maximizes the service life of igus products. Additionally, a digital dashboard is available that can visualize all the information and movement data of connected sensors. This takes out any guesswork and makes monitoring equipment condition across an entire system simple and efficient.

Request a live demo of the i.Cee dashboard

Conclusion

The integration of machine learning into predictive maintenance holds immense potential for transforming industrial automation. By leveraging machine learning's ability to continuously learn and improve from data, predictive maintenance systems can become more accurate, efficient, and cost-effective.

The adaptability of machine learning algorithms ensures that maintenance schedules are optimized, equipment lifespan is extended, and safety is enhanced. However, it is crucial to address considerations such as data quality, system integration, and the need for skilled personnel to fully harness the benefits of this technology.

As industries continue to embrace AI and machine learning, the synergy between predictive maintenance and these advanced algorithms will undoubtedly drive innovation and operational excellence, paving the way for a more reliable and efficient future in industrial automation.