Change Language :

PFAS in igus® materials

At a glance:

- Most chainflex® cables do not have PFAS substances

- Depending on the PTFE content, plain bearings may be affected by a possible PTFE ban

- Many iglide® materials do not contain PTFE; no traces of 96 of the most important PFAS substances were detected in other iglide® materials

- If PTFE is not banned, iglide® materials are generally not affected

Need more information?

Reach out to us by either filling out the form below or booking an appointment with our specialists to discuss your specific PFAS- or PTFE-related requirements.

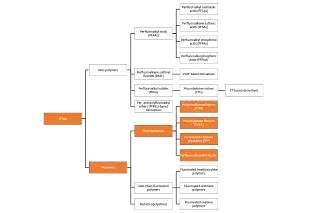

Diagram 1: Classification of PFAS

What are PFAS?

Per- and polyfluoroalkyl substances (PFAS) are industrial chemicals that are used in numerous industrial processes and consumer products due to their special technical specifications. They essentially consist of carbon (C) and fluorine (F) atoms. Apart from this, PFAS molecules can have completely different structures, which means that they can have many different specifications. Diagram 1 gives an overview of the classification of PFAS, initially into polymers and non-polymers. PFAS can be gaseous, liquid or solid. According to the OECD database, the group of substances includes more than 4,700 different compounds, according to the EPA (Environmental Protection Agency) more than 9,000 and according to the EU Commission even more than 10,000 compounds. From this you can see that it is neither a unique nor a constant value. The stated value is usually based on estimates.

In the subgroup of perfluoroalkyl substances (non-polymers), the compounds perfluorooctanoic acid (PFOA) and perfluorooctane sulfonic acid (PFOS) have been studied the most thoroughly. Like many PFAS, these two compounds are persistent and can now be found in the environment, the food chain and in people. PFOA and PFOS have a proven negative impact on health. Together with PFHxs and PFNA, they account for 90% of the current contamination with PFAS.

In the subgroup of polymers, a distinction is made between fluoropolymers/fluoroplastics and polymers with fluorinated side chains. The fluoropolymers consist of a carbon chain with directly attached fluorine atoms. This makes them so strong that they cannot break down into toxic substances. According to the OECD, fluoropolymers are "products of low concern", non-toxic and non-bioaccumulative, i.e. they cannot accumulate in organisms. The only danger is the possible use of toxic additives during production in the form of emulsifiers. Fluoropolymers are used, for example, in coatings, seals and cable insulation. PTFE is a fluoropolymer.

Polymers with fluorinated side chains also consist of a carbon chain, but with lateral carbon chains to which the F-atoms are first attached. As a result, these polymers are less strong, and there is a risk of losing the side chains. They are used, for example, as impregnating agents.

PFAS-tested chainflex® cables

A ban on PFAS was already being discussed at EU level at the beginning of 2023, as the substances do not decompose naturally and are therefore permanently present in the environment as "forever chemicals". The vast majority of our chainflex cables are considered PFAS-free based on our testing of 96 PFAS substances.

The following chainflex articles, which may contain these substances due to their design, are the exception:

List of PTFE-free Materials

White Paper: PFAS In Focus - Planned Restrictions, Challenges, and Solutions for the Industry

This white paper explains what PFAS are, why they are so common, and why they are problematic. It also dives into igus' material development, what we are doing about the PFAS situation, and our PTFE-free and PFAS-tested products.

iglide® PFAS-tested material statements

PFAS-tested: iglide® materials without critical PFAS compounds

All iglide materials labeled as "PFAS-tested" were tested for the 96 PFAS substances considered critical for the environment and health using the SQP M1227 test method (LC-MS/MS and GC-MS) and do not contain any substances >0.1% by mass. This category excludes substances from the group of fluoropolymers.

Additional PFAS-tested Material Statements

With in-house development and own test laboratory for PTFE and PFAS alternatives

We have a very high level of vertical integration. Among other things, we operate our own development department for materials, an in-house compounding department, a technical center for process engineering tests and an extensive test laboratory for materials and products. On this basis, we have developed possible alternatives to PTFE and PFAS that are not more expensive and do not contain any problematic ingredients that could lead to a ban in the future. We have tested these alternatives in our test laboratory under real conditions for the changed material compositions and their possible effects on the specification of the materials.

The results speak for themselves: materials with substituted PTFE show significantly better performance in terms of friction and wear behavior compared to the original PTFE-containing materials. The already good wear rates are reduced by an average of around 60% thanks to the new development of PTFE substitution. Thanks to the clever design of the formulations, the other material properties in terms of temperature stability, mechanical load-bearing capacity and shrinkage behavior remain almost the same. Thanks to new formulations, extensive testing and customized production processes, we can now offer you a wide range of PTFE and PFAS-tested materials and products.

Current legal situation for PFAS in plain bearings

Last updated date: April 20th, 2023

EU: The use of PFOS has been largely banned since 2006 and that of PFOA since July 2020 - you can find our confirmation here. Five European countries (Germany, Netherlands, Denmark, Sweden, Norway) have submitted a proposal for the general restriction of PFAS, which was published by the ECHA (European Chemicals Agency) on 7 February 2023. This proposal is a first step in a long regulatory process and will be reviewed by all stakeholders. The first phase of consultation by all stakeholders ran from 22 March 2023 to 22 September 2023. The proposed PFAS regulation would probably come into force in EU member states in 2026 at the earliest. Possible transition periods of up to 13 years are possible from the date of entry into force.

USA: The EPA has issued a final rule adding five PFAS substances to the list of over 170 PFAS substances. These are reportable under the Toxics Release Inventory (TRI), a centralised database for public reporting of chemicals. Fluoropolymers are not included in the TRI list.

Contact Us

Questions or product information? Please contact:

Customer Service

Customer Service:

Phone: Monday to Friday from 8 am - 8 pm

LiveChat: 24 hours

Book a Call

Book an Appointment with a Product Expert