Change Language :

Ready-to-install energy supply systems streamline your production

Increase your factory's productivity and improve product quality with readychain®

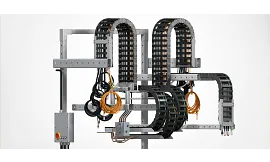

Maximize efficiency and minimize downtime with igus® readychain® — a fully assembled, ready-to-install energy supply system that integrates chainflex® cables and e-chain® cable carriers. Designed to streamline production processes, readychain® systems help reduce installation times, simplify procurement, and improve machine reliability across a wide range of industries.

Preassembled Energy Chain Systems Tailored to Your Needs

igus® handles the entire procurement, assembly, and delivery process, ensuring your cable management system arrives on time and ready for integration. Whether you're automating packaging machines, gantries, machine tools, or production lines, our systems are designed for seamless plug-and-play installation.

Simplify Ordering and Save Costs

Each readychain® system is delivered with a single part number and purchase order, reducing processing time and administrative overhead. There’s no need to track dozens of individual cables, connectors, or components. Reordering becomes fast and hassle-free.

Proven Performance, Global Reliability

igus® e-chain systems are trusted inhundreds of thousands of applications, from compact devices to demanding environments like steel mills and robotic systems. With over 1,300 chainflex® cables available from stock, our cable assemblies are built for durability, flexibility, and optimized movement in dynamic applications.

Fully Customizable and Manufacturer-Compliant

Choose from pre-configured cable assemblies or fully customized harnesses built to your specific needs. Our systems can be designed to comply with over 20 global manufacturer standards, including Siemens, Beckhoff, and Allen Bradley. All chainflex® cables come with an up to 4-year UL-verified service life guarantee.

Expert Support and On-Site Services

From design to delivery and installation, our readychain® experts provide full support, including on-site installation and inspection services. Let us help you configure a system that increases uptime and delivers long-term performance.

Readychain Benefits

Application Stories

Frequently Asked Questions

Pre-assembled cable carriers are complete plug-and-play systems including an energy chain, chainflex® cables, and connectors—preconfigured and tested. With igus® readychain® systems, you can reduce installation time by up to 95% while eliminating integration risks.

igus® validates every component in its 3,800 m² test lab. Results from these tests are published and fed into the igus® service life calculator, allowing accurate lifespan predictions under real-world conditions.

Yes. igus® allows full customization—choose from 1,400+ chainflex® cable types, hundreds of energy chain styles, and connectors from all major manufacturers. Use the readycable and e-chain configurator to design your system. Contact your local sales representative to review your application.

All manufacturing industries such as automation, robotics, machine tools, packaging and other motion applications gain the most. These systems are ideal where uptime, predictable service life, and compact installation are priorities.

igus® uses tested CFX clamps, strain relief plates, and integrated interior separators to reduce cable fatigue and prevent stress at the connectors—ensuring electrical and mechanical stability over millions of cycles.

Yes. Nearly all chainflex® cables carry UL approval, CE conformity, and EAC certification. Many also comply with NFPA 79 and ISO Class 1 cleanroom standards, ideal for regulated or sensitive environments.

igus® supports connector brands like Harting, LAPP, TE, Phoenix Contact among others. Assemblies can include over molded, field-attachable, or hybrid connectors with customer-specific pinouts and labeling.

Standard drive cables found in our online configurator ship within 5-10 working days. Custom solution lead times vary based on the complexity of the design but can ship within 10 to 20 working days. Contact your local igus representative or product manager for current lead times.

igus® tests systems at speeds up to 10 m/s and accelerations to 50 m/s² across a range of bend radii, up to 70 million cycles. These parameters ensure readiness for high-performance, continuous-flex environments.

Yes. igus® chainflex® cables are rated for 10–100 million cycles depending on application. Browse tested cables on the chainflex® cable page by bend radius, speed, or voltage class.

igus® designs carriers with tight bend radii and optimized fill percentages, reducing system footprint. Custom bracket designs also help adapt to limited mounting space while protecting cables.

igus® customers typically reduce total system costs due to reduced design time, minimized rework, increased throughput, decreased logistics costs and faster installations. There’s also lower risk of miswiring or early failure.

Yes. igus® offers triflex® R robotic cable management with integrated chainflex® torsion-rated cables, retraction systems, and pre-pinned connectors for 6-axis robots.

igus® offers i.Sense condition monitoring and i.Cee predictive maintenance tools to track wear and prevent unplanned downtime through real-time analytics.

Every readychain® undergoes 100% electrical and mechanical QA. Tests include cable continuity, pinout validation, strain relief integrity, and visual inspection. Documentation is available on request. All cable and wire harness assemblies are made to IPC/WHMA-A-620E standards.

Browse readychain® products

Four different readychain products are available for customers: Basic, which includes an e-chain filled with chainflex cables but without connectors; Standard, which includes an e-chain filled with chainflex cable assemblies; Standard+, which includes everything found in Standard along with mounting plates; and finally Premium, which comes with a transport and assembly rack as well as the complete system available with Standard. Regardless of the chosen product, the entire system remains single source and only requires a single PO for easy reordering.

Browse the Engineer's Toolbox

Contact Us

Questions or product information? Please contact:

Customer Service

Customer Service:

Phone: Monday to Friday from 8 am - 8 pm

LiveChat: 24 hours

Book a Call

Book an Appointment with a Product Expert