Change Language :

Condition monitoring for automotive parts suppliers

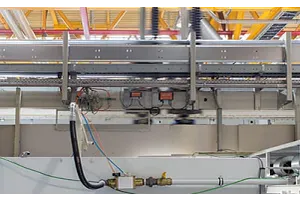

Engine factory for a large German car manufacturer in Austria

In the automotive industry, reliability is of the utmost importance. Whole vehicles as well as individual components, such as engines, go through production lines with a very high degree of automation. If production stops here, it quickly leads to expensive losses. Therefore, it is important for vehicle manufacturers and suppliers to be able to rely on fail-safe components. For this reason, an Austrian engine manufacturer relies on smart plastics from igus®. These smart plastic sensors measure wear during operation and notify the user early enough to plan a repair or an exchange.

Twice as safe: abrasion and breakage monitoring

The i.Sense EC.W ("W" for "wear") abrasion monitoring system is also used in the energy chain. This is a sensor chip installed in the crossbar which continuously measures the condition of the sliding e-chain® as it travels. If the abrasion is so advanced that the end of the chain's service life is approaching, the sensor reports this and triggers a signal.

The use of the i.Sense EC.B modules ("B" for "break") is much more decisive here. They monitor the condition of the chain using a polymer wire inside the energy chain and a sensor unit. In the past, visual inspections of e-chain® systems have shown no issues, but two weeks later the chain has failed. These situations can be prevented by the breakage monitoring system. However, a lot of fine-tuning still had to be done at the start of the beta phase. This is because the temperature in a factory has a major influence on the length of the chain as well as the pretension of the polymer wire. It was necessary to determine limit values in order to distinguish between "normal" expansion and actual incidents.

At the Austrian engine plant, the i.Sense modules from igus® have already been named the innovation of the month. There are currently considerations and plans to equip around 50 to 60 energy chain systems from igus® with breakage monitoring. The three test systems are already at the point where the system stops in real operation and the responsible machine setters have to take action. After a visual inspection, they can decide whether it was a false alarm or whether there is an actual need for action. This means that even during the current beta phase, expensive, consequential damage can be avoided and the gantries can be moved safely.

Contact Us

Questions or product information? Please contact:

Customer Service

Customer Service:

Phone: Monday to Friday from 8 am - 8 pm

LiveChat: 24 hours

Book a Call

Book an Appointment with a Product Expert