In the world of engineering and manufacturing, the lead screw plays a pivotal role. Renowned expert Dr. Emily Carter, a leader in mechanical design, once stated, "Lead screws are essential for precision movement in many applications." Their unique function allows for linear motion, making them indispensable in various sectors.

From 3D printers to CNC machines, lead screws are everywhere. They convert rotary motion into linear motion efficiently. These mechanical components can be found in industrial automation, robotics, and medical devices. However, not all lead screws are created equal. Material choice and design impact performance significantly. Users often overlook these factors, leading to inefficiencies.

Understanding lead screw applications is crucial for optimizing productivity. While they are highly versatile, selecting the wrong type can result in serious setbacks. Engineers must research and reflect on their specific needs. Only then can they fully harness the potential of lead screws in their designs.

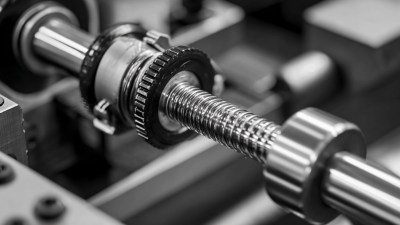

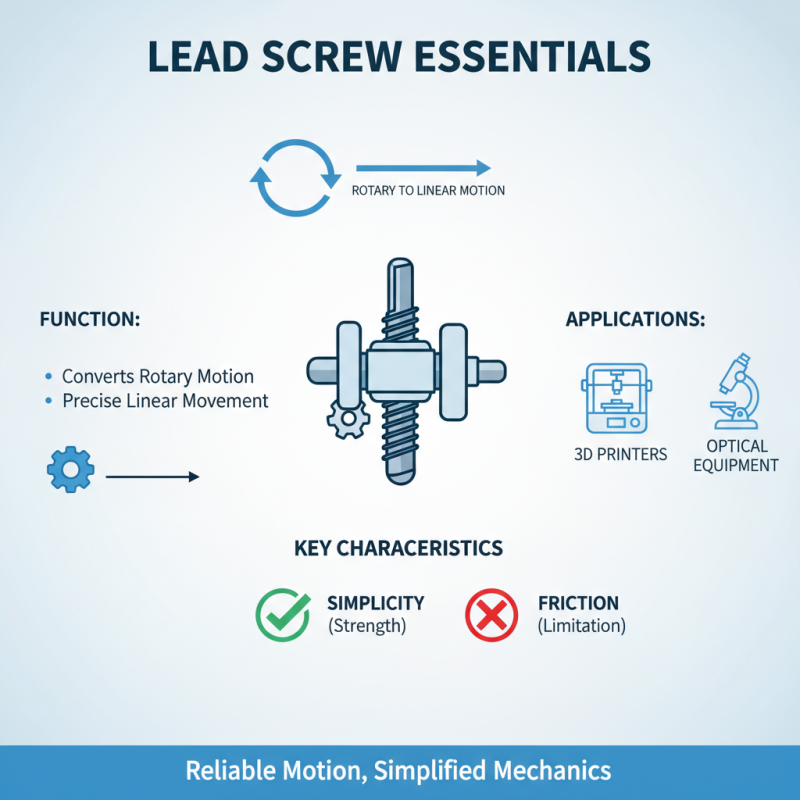

Lead screws play a vital role in various applications, offering precise linear motion. These mechanical components convert rotary motion into linear movement. Their simplicity is both a strength and a limitation. While they are easy to design and use, they come with friction issues that can affect performance in some situations.

In industries like robotics and automation, lead screws are crucial. They provide reliable movement for components like actuation systems and 3D printers. These applications often require accuracy over speed. However, reliance on lead screws can lead to maintenance challenges. Users must regularly check for wear and lubrication. These factors can impact the overall efficiency and lifespan of the system.

Moreover, lead screws find their place in medical devices, where precision is critical. They help in devices like surgical tables and diagnostic tools. Despite their strengths, one must consider alternative methods, such as ball screws, for higher efficiency and lower friction. Balancing performance and ease of maintenance is essential for optimal results.

Lead screws play a significant role in various applications. These components require careful consideration in material selection. Common materials include stainless steel, bronze, and nylon.

Stainless steel offers durability and resistance to corrosion. It is often used in environments exposed to moisture. However, it can be costly compared to other options.

Bronze is another popular choice. It provides excellent wear resistance and low friction. Many industries benefit from its performance. On the downside, bronze lead screws may not be suitable for every environment due to their susceptibility to certain chemicals.

Nylon, while lightweight and less expensive, comes with its own challenges. It is less durable compared to metals. However, it can handle light loads effectively. Its flexibility can lead to performance issues under heavy stress.

Each material has its pros and cons. Understanding these nuances is key for successful lead screw applications. Choosing the right material may not be straightforward, but the effort is crucial.

Lead screws play a crucial role in numerous applications, providing reliable motion control in various industries. The key features of lead screws include their ability to convert rotary motion into linear motion efficiently. This is particularly useful in automation systems and machine tools. According to recent industry reports, lead screws can achieve precise positioning with a typical accuracy of ±0.01 mm, making them indispensable for tasks requiring high precision.

Another significant benefit of lead screws is their load-carrying capacity. They can support substantial weights while maintaining structural integrity. Depending on the design, some lead screws can handle loads exceeding 5000 N. This makes them suitable for heavy-duty applications. Despite their advantages, it's vital to address potential shortcomings. Wear and friction can degrade performance over time, necessitating regular maintenance. Users must consider these factors when selecting lead screws for their projects.

The materials used in lead screw manufacturing also impact performance. Common options include stainless steel and bronze. Each material offers unique benefits in terms of durability and cost. However, the right choice may not always be evident and could lead to complications. It's essential to assess the specific application needs to avoid critical failures. Understanding these features helps optimize the use of lead screws across various applications.

Lead screws are essential components in many industries. They convert rotary motion into linear motion effectively. These screws are used in automation, robotics, and manufacturing processes.

Manufacturing is one of the primary industries utilizing lead screws. They assist with precise movement in CNC machines. In addition, robots use lead screws for accurate positioning in assembly lines. A small error in positioning can lead to significant delays and costs.

In the medical field, lead screws play a crucial role. Equipment like surgical tables and imaging devices rely on them for movement. Accuracy is vital in healthcare. Any malfunction can impair patient care. Regular maintenance is necessary.

**Tips:** Ensure lead screws are properly lubricated. This prevents wear and tear, extending their lifespan. Additionally, monitor the alignment regularly to avoid issues.

In the aerospace industry, lead screws are key to controlling aircraft mechanisms. They help in landing gear and wing adjustments. However, designing for reliability can be challenging. Components must withstand harsh environments.

**Tips:** Consider using higher-grade materials to enhance durability. This investment can increase safety and performance over time. It's essential to evaluate the entire system's compatibility with lead screws.

Lead screws play a critical role in modern technology, powering devices in diverse applications. They convert rotary motion to linear motion. According to a recent industry report, the global lead screw market is projected to grow at a compound annual growth rate of over 5% from 2021 to 2026. This growth indicates a rising interest in their innovative uses.

In robotics, lead screws are vital for precision movements. They enable accurate positioning in robotic arms and automated systems. Their low cost and ease of integration make them attractive. However, not all lead screws perform optimally under heavy loads. Wear and lubrication issues can arise, necessitating careful selection for each application. The manufacturing sector increasingly relies on lead screws for CNC machines. They provide repeatable accuracy, crucial for mass production. A report suggests that automated machinery incorporating lead screws has increased efficiency by 20% in some plants.

In aerospace, lead screws offer solutions for actuation mechanisms. They help control flaps and landing gear. Though reliable, they can introduce complexity in design. Engineers must balance weight and strength to ensure safety. The automotive industry is also adopting lead screws for electric vehicle components. Their reliability is essential, yet they sometimes face challenges in maintaining performance in extreme conditions. As technology advances, new materials and designs may emerge to address these concerns.