Rod ends are pivotal components in machinery, offering crucial benefits in various applications. According to a report by the Machinery Components Association, the global rod end market is projected to grow by 5% annually over the next five years. This growth highlights their importance in industries such as automotive, aerospace, and heavy equipment.

Industry expert Dr. Emily Hart states, "Rod ends are often the unsung heroes of mechanical systems, ensuring reliability and flexibility." These components allow for angular movement and accommodate misalignment, making them essential in complex machinery. Their design, often overlooked, significantly impacts performance and efficiency.

Despite their advantages, the rod end market faces challenges. Quality control and material durability are critical issues. Some rod ends fail under stress, leading to unexpected maintenance costs. Continuous improvements in production and material science are needed to enhance their reliability. Addressing these concerns is essential for future growth in this vital sector.

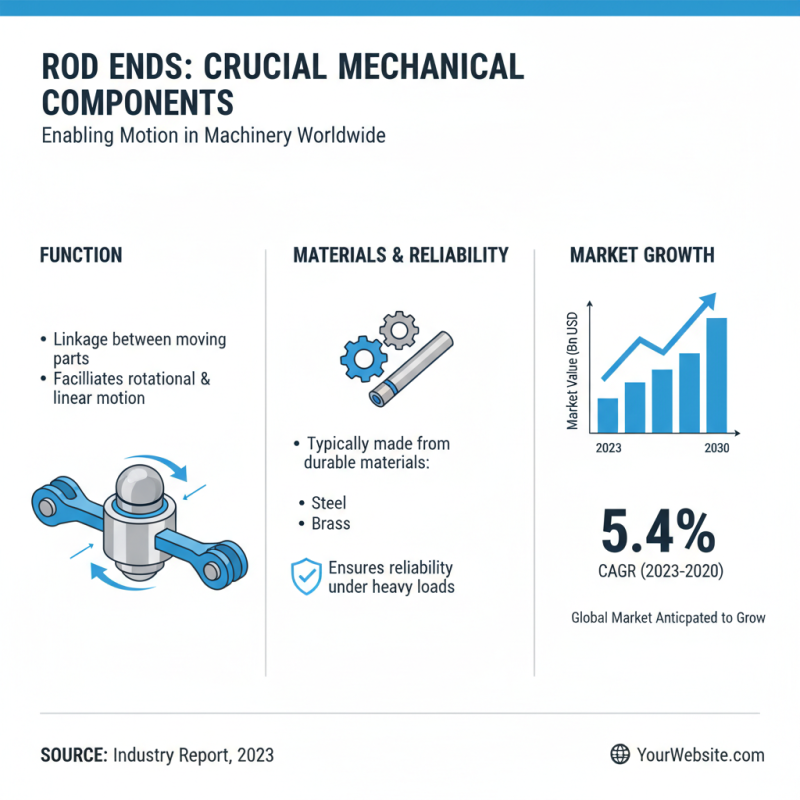

Rod ends are specialized mechanical components often used in various machinery. They serve as pivot or connection points in systems where linear and rotary motions occur. Typically, a rod end consists of a spherical bearing in a housing, allowing for multidirectional movement. This design enables smoother operation of machinery parts, especially in applications requiring flexibility.

In construction and automotive industries, rod ends have critical roles. They can connect control rods to different mechanical components. This connection allows for significant angular movement. The range of motion can be both an advantage and a concern. If not properly designed, excessive movement may lead to premature wear. Choosing the right type and size is crucial for longevity.

Rod ends find uses in many applications, from linkages in aircraft to adjustable links in heavy machinery. Their simplicity is a double-edged sword. While they are straightforward, improper installation can lead to failures. Regular maintenance is essential to ensure they function properly. Inspecting rod ends for signs of wear or damage can prevent costly downtimes. Making informed choices reduces these risks significantly.

Rod ends play a crucial role in machinery, providing flexibility and swivel capabilities. There are several types used across various applications. Each type serves a specific purpose, adapting to different loads and movement requirements. For example, spherical rod ends allow for a full range of motion. They are ideal for linking parts that need to pivot, such as in suspension systems.

Another type is the plain rod end, which offers high strength for static applications. This type is often found in heavy machinery, where reliability is essential. Data indicates that approximately 30% of machinery failures stem from linkage components. Using the right type of rod end can significantly reduce wear and increase safety.

However, challenges exist. Some rod ends may wear out faster under extreme conditions. Environmental factors like dirt and moisture can also lead to premature failure. Regular inspection and maintenance are critical. Observing signs of wear can extend the life of these components. It’s a matter of balancing performance with the right type of rod end for the task.

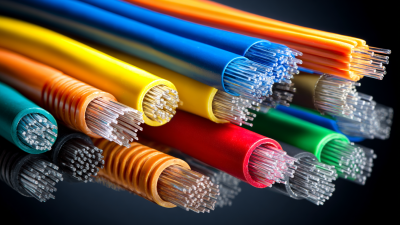

Rod ends are crucial components in various mechanical systems. They serve as linkages between different moving parts, allowing for rotational and linear motion. These components are typically made from durable materials like steel or brass, ensuring reliability under heavy load conditions. According to a recent industry report, the global rod end market is anticipated to grow at a compound annual growth rate (CAGR) of 5.4% from 2023 to 2030, indicating their increasing importance in machinery.

Functionally, rod ends provide a pivot point. This capability allows for precise control of movement. In many applications, they are used in conjunction with bearings, which help reduce friction and wear. A study found that using high-quality rod ends can improve overall mechanical efficiency by up to 15%. However, improper installation or maintenance can lead to premature failure, which often goes unnoticed until it affects machine performance.

Attention to detail is essential when selecting rod ends. Factors such as load capacity, size, and intended motion must be considered. Although many systems are designed to operate smoothly, unexpected issues can arise. Regular checks are vital to ensure that rod ends perform as intended. It's a stark reminder that neglecting small components can result in bigger problems down the line, impacting overall productivity and safety.

Rod ends are important components in many machines. They connect rods and shafts, allowing movement and articulation. Industries like automotive, aerospace, and robotics rely on these parts. Rod ends facilitate smooth operation, reducing wear and tear. In the automotive sector, for instance, they are used in steering systems and suspension links. These applications require high strength and durability.

In aerospace, rod ends help maintain precision in flight control systems. Their lightweight yet strong design supports critical functions. Robotics also utilizes rod ends for joints that need flexibility. The choice of material is crucial; it must withstand harsh environments. Sometimes, the ideal size may not fit all designs, requiring adjustments.

Despite their usefulness, rod ends can face issues. Misalignment can lead to premature failure. Regular maintenance is essential to prevent this. However, not every operating condition gets the attention it needs. Some setups overlook critical wear checks. Balancing performance with longevity remains a challenge. Better practices could improve the reliability of these components in various applications.

Rod ends are critical components in machinery design. They connect rods and shafts in various applications. These parts facilitate smooth movement at joints. Their simple design allows for complex maneuvers in a compact space. This versatility enhances machine efficiency, particularly in limited areas.

One significant benefit of using rod ends is their adaptability. They can pivot and swivel, accommodating different angles. This characteristic helps reduce stress on other components. Their durability is another advantage. Rod ends withstand heavy loads and harsh conditions. However, they can wear out over time. Regular inspection is necessary to maintain performance.

Moreover, rod ends improve overall safety in machinery. By allowing for better alignment, they minimize the risk of failure. Improperly aligned components can lead to disastrous consequences. Adjustments may be needed, which requires thoughtful planning. Occasionally, users overlook this aspect, leading to increased downtime. Being aware of these factors enables better machine design and operation.