In today's fast-paced industrial landscape, maximizing workspace efficiency has become a pivotal focus for businesses aiming to enhance productivity and reduce operational costs. The integration of innovative gantry systems is revolutionizing how companies approach material handling and automation. According to a recent report by the International Federation of Robotics, the implementation of advanced automation solutions, including gantry systems, can lead to an increase in productivity by up to 30%. This shift not only offers a streamlined approach to managing workflows but also facilitates a reduction in labor costs and minimizes human error.

Gantry systems, characterized by their modular design and versatility, are becoming increasingly popular in various sectors, from manufacturing to logistics. A study by MarketsandMarkets indicates that the global gantry crane market is expected to reach $7.8 billion by 2025, driven by the soaring demand for improved operational efficiencies. As businesses look to adopt cutting-edge technologies that enable them to stay competitive, gantry systems are proving to be an essential tool for transforming workspace dynamics. By leveraging these systems, companies can optimize their operational capabilities, ensuring they meet the demands of a rapidly evolving marketplace while maintaining a high level of safety and precision.

In today’s fast-paced industrial environment, enhancing productivity is critical, and advanced gantry systems play a pivotal role in revolutionizing workspace efficiency. These systems are designed to meet the demands of modern workspaces by streamlining operations and reducing downtime. With customizable configurations and automated features, gantry systems empower workers to move materials quickly and precisely, thus optimizing workflow.

**Tip:** Consider integrating your gantry system with automated software to manage tasks more effectively. This can ensure that materials are handled and relocated seamlessly, reducing unnecessary manual labor and allowing employees to focus on more strategic tasks.

Moreover, ergonomic designs and adjustable heights in gantry systems contribute to a safer and more comfortable work environment. By allowing workers to operate at their preferred height, these systems help minimize strain injuries and enhance concentration.

**Tip:** Regularly assess your gantry system's layout and functionality to ensure it meets your operational needs. Engaging employees in this evaluation can also encourage them to share insights that may further boost productivity.

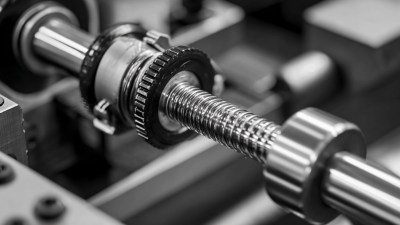

Innovative gantry systems are transforming workspace efficiency by providing optimized solutions for various machinery applications. One of the key features of these systems is their ability to enhance dynamic stability and structural integrity through advanced finite element analysis and optimization techniques. This ensures that the high-precision machine tools operate with superior rigidity, leading to improved machining efficiency and surface quality. By maintaining a steady operational environment, gantry systems can effectively reduce vibrations and distortions, which are critical for achieving high accuracy in production processes.

Furthermore, these systems allow for exceptional versatility in workspace utilization. The modular design of gantry systems enables easy adaptation to diverse tasks and machinery configurations. This flexibility not only saves space but also facilitates quicker setups and transitions between different workflows. With their innovative structure, gantry systems promote more organized work environments, minimizing clutter and maximizing accessibility. As industries strive for greater productivity, the integration of innovative gantry systems stands as a pivotal advancement in enhancing overall operational effectiveness.

| Feature | Description | Benefits |

|---|---|---|

| Modular Design | Flexible layouts that can be customized based on workspace needs. | Maximizes space efficiency and adaptability. |

| Lightweight Materials | Constructed with high-strength, lightweight composites. | Easier handling and reduced installation time. |

| High Load Capacity | Designed to handle heavy-duty loads safely. | Enhances operational efficiency for heavy lifting tasks. |

| Mobile Solutions | Equipped with casters for easy relocation. | Increases flexibility and responsiveness to workspace changes. |

| Ergonomic Features | Designed to reduce strain on workers. | Promotes safety and well-being, reducing workplace injuries. |

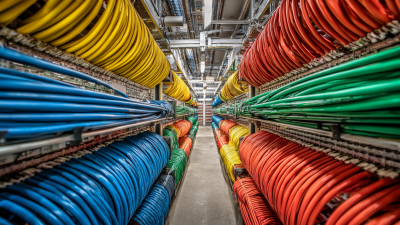

| Smart Technology Integration | Compatible with automation and IoT applications. | Optimizes workflow and data collection for analytics. |

| Customizable Accessories | Various attachments and add-ons available. | Tailored to specific task requirements, enhancing productivity. |

Integrating gantry systems into existing workflows represents a transformative approach to enhancing workspace efficiency. By leveraging these automated systems, organizations can streamline operations, reduce manual labor, and minimize the risk of errors. The adaptability of gantry systems allows them to fit seamlessly into various industries, from manufacturing to logistics, making it easier for businesses to upgrade their existing processes without overhauling entire systems.

Moreover, the integration of gantry systems enhances productivity by optimizing the movement of materials and tools. With precise positioning and the ability to manage heavy loads, employees can focus on higher-value tasks rather than being tied down by repetitive, physical labor. This synergy not only improves workplace ergonomics but also fosters a culture of innovation, where team members can explore creative solutions in a more efficient environment. As companies invest in these technologies, they are not just upgrading equipment; they are redefining their operational capabilities for sustained growth and competitiveness.

Gantry systems are becoming a game-changer for businesses looking to enhance their workspace efficiency. With innovative designs that maximize vertical space and streamline operations, they enable companies to optimize workflows in various industries. For example, a Minnetonka-based company focused on neurosurgery recently enhanced its surgical suites by implementing advanced gantry systems, which not only improved patient outcomes but also the efficiency of medical procedures.

In another realm, aerospace machining leaders are leveraging cutting-edge technologies alongside gantry solutions to boost precision and productivity in their operations. By integrating digital-native systems, operators can now achieve more efficient machining processes, demonstrating the immense potential that gantry systems hold for businesses aiming to remain competitive.

Tips: When considering the implementation of gantry systems, ensure to assess your workspace layout thoroughly. This can help in optimizing the design for maximum efficiency. Additionally, training your staff on the new systems can significantly reduce downtime and enhance productivity, making the transition smoother and more beneficial. Lastly, stay updated with industry advancements to continually refine your operations.

As industries continue to embrace automation and advanced technologies, gantry systems are poised to play a crucial role in the evolution of workspace design. Recent data from the Global Gantry Systems Market Report indicates a projected growth rate of over 6.4% annually through 2025, highlighting the increasing demand for these innovative solutions. This trend is driven by the need for improved efficiency and flexibility in various sectors, including manufacturing, logistics, and construction. The integration of smart gantry systems equipped with sensors and AI capabilities allows for real-time data collection and analytics, enhancing operational workflows and workspace management.

Furthermore, future trends in gantry technology are expected to incorporate modular designs and lightweight materials, which can significantly impact workspace layout and ergonomics. According to a study published by the International Association of Structural Engineers, the use of advanced materials can reduce the weight of gantry systems by up to 30%, enabling more versatile applications in confined spaces. As businesses increasingly prioritize adaptive environments to maximize productivity, the design of workspaces will evolve to accommodate these cutting-edge gantry solutions, fostering a more efficient and collaborative atmosphere. This shift not only optimizes operational efficiency but also prepares organizations for the future of work, where adaptability and innovation are key drivers of success.