Lead screws play a crucial role in precision engineering applications, serving as the backbone for a variety of mechanical systems ranging from CNC machines to robotic actuators. According to a report from Grand View Research, the global linear motion system market, which prominently features lead screws, was valued at approximately $26 billion in 2020 and is projected to grow at a CAGR of 6.2% through 2028. This growth highlights the increasing demand for high-precision components in industries such as aerospace, automotive, and medical devices.

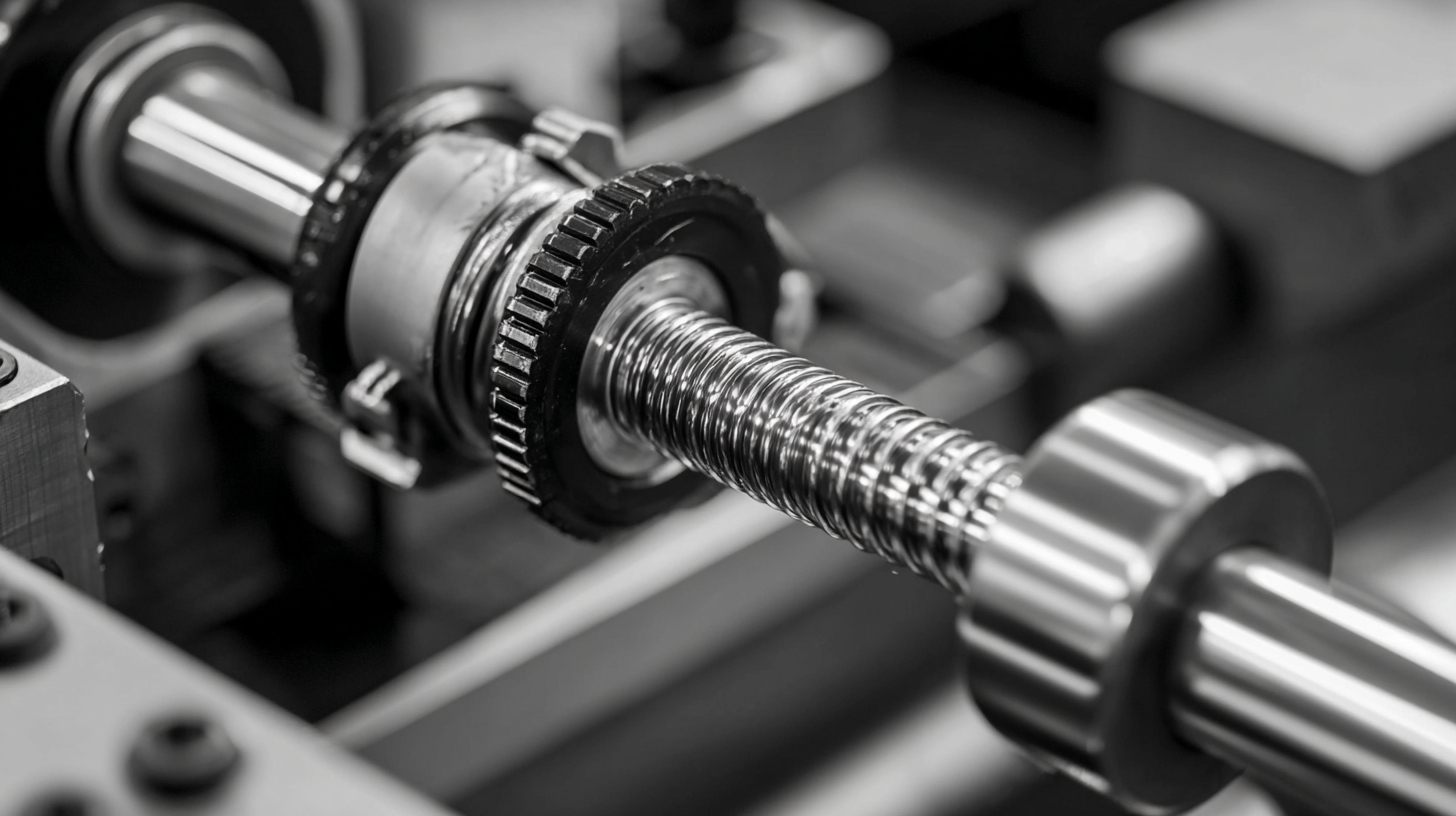

Lead screws, known for their ability to convert rotational motion into linear motion with minimal backlash and high positional accuracy, are essential in environments where precision is non-negotiable. As engineering continues to move towards automation and enhanced efficiency, understanding the intricacies of lead screws and their operational parameters becomes imperative for optimizing design and performance in precision engineering applications.

Lead screws are critical components in precision engineering, serving various applications that require accurate linear motion control. They come in different types, each tailored for specific functionalities. For instance, standard lead screws with a single-thread design offer reliable motion for basic applications, while double-start lead screws provide quicker linear travel and improved efficiency. Additionally, innovations such as combination wipers for precision ball screws enhance the performance and longevity of these mechanisms by removing debris and reducing wear during operation.

In the context of the latest advancements, miniature metric ball screw assemblies demonstrate how companies are responding to the growing demand for compact and efficient solutions. These assemblies are available in varying diameters and come with customizable lead lengths and nut types, catering to diverse precision engineering requirements. Furthermore, actuators featuring unique right/left thread designs signify advancements in linear motion technology, enabling symmetrical movements and increased operational efficiency. These developments underscore the integral role of different lead screw types in enhancing precision and performance across various engineering applications.

| Type of Lead Screw | Functionality | Common Applications | Advantages | Limitations |

|---|---|---|---|---|

| Acme Lead Screw | Converts rotary motion into linear motion | Lathes, CNC machines | Good load capacity, durable | Higher friction, lower efficiency |

| Ball Screw | Uses ball bearings to reduce friction | Robotics, automated machinery | High efficiency, low friction | Higher cost, requires precise alignment |

| Trapezoidal Lead Screw | Designed for efficiency in lifting applications | Cranes, elevators | Moderate friction, good balance | Limited speed capabilities |

| Lead Screw with Square Thread | Used in applications requiring heavy loads | Presses, jacks | Excellent load handling | Inefficient for high-speed applications |

The role of thread design in enhancing lead screw performance is critical in precision engineering applications. Lead screws are commonly used in machinery and equipment where accurate linear motion is required. The geometry of the threads, including factors such as thread pitch, profile, and depth, significantly influences the lead screw's efficiency, load capacity, and wear resistance. A well-designed thread can minimize friction and play, ensuring smoother movement and greater precision.

Moreover, the material used in thread construction can also impact performance. For instance, selecting a harder material for the threads can improve durability and wear resistance, while a softer material might allow for easier machining and customization. Additionally, variations such as square or trapezoidal thread profiles can be employed to meet specific application requirements, affecting the lead screw’s mechanical advantage and backlash characteristics. Such considerations are essential for engineers who aim to optimize the functionality and reliability of lead screws in demanding environments.

When selecting lead screws for precision engineering applications, the choice of material plays a crucial role in determining their strength and durability. Common materials include stainless steel, brass, and plastic composites, each offering unique attributes. Stainless steel, for instance, boasts excellent tensile strength and corrosion resistance, making it ideal for demanding environments. However, its weight can be a disadvantage in applications where minimizing mass is critical.

On the other hand, brass lead screws provide good wear resistance and are lighter than steel, which can enhance efficiency in motion systems. They are particularly suitable for applications where low friction and reduced noise operation are desired. Plastic composites, while not as strong as metal options, excel in applications requiring lightweight components with resistance to corrosion and chemicals. The right material choice ultimately hinges on the specific requirements of the application, such as load capacity, environmental conditions, and the desired lifespan of the lead screw, significantly influencing overall performance and reliability in precision engineering.

Lead screws are essential components in robotics and automation systems, offering a reliable means of converting rotational motion into linear motion with high precision. Their design allows for minimal backlash, which is critical in applications requiring exact positioning, such as robotic arms and CNC machines. By utilizing materials and coatings that reduce friction and wear, lead screws enhance the longevity and efficiency of automated systems.

**Tips:** When selecting a lead screw for your robotic application, consider the load requirements and environment. For instance, in high-speed operations, a lead screw with a lower pitch may provide better control. Likewise, integrating proper lubrication can significantly improve the performance and durability of lead screws in automation systems.

In addition to robotics, lead screws are increasingly used in automation systems for tasks such as packaging, assembly, and material handling. Their adaptability makes them ideal for various industries, from manufacturing to healthcare, where precision and reliability are paramount. By ensuring that the lead screws are suited to the specific application’s parameters, engineers can achieve optimal performance and minimize downtime.

**Tips:** Regularly inspect the lead screw for signs of wear and misalignment to prevent potential failures. Additionally, consider utilizing sensors to monitor their performance and make real-time adjustments as needed.

In precision engineering, lead screws play a crucial role in converting rotational motion into linear movement. Their efficiency and accuracy are pivotal metrics that determine the performance of various applications, ranging from CNC machines to medical devices. According to a report by the Precision Engineering Society, lead screw systems can achieve positional accuracy of up to 10 micrometers, depending on factors such as pitch, material, and manufacturing tolerance. This level of precision is essential in industries where even micro-level discrepancies can lead to significant operational failures.

Furthermore, the efficiency of lead screws is often quantified by their lead angle and the coefficient of friction between the screw and nut. Industry studies reveal that a lead screw with a lead angle of 5 degrees can exhibit up to 90% efficiency under optimal conditions, while higher lead angles can enhance speed but may compromise accuracy. As highlighted in the latest Mechanical Engineering Report, advancements in materials such as composites and coatings have improved the frictional properties of lead screws, resulting in better performance and longer service life. These developments are critical for engineers aiming to enhance the reliability of precision systems.

This chart presents the efficiency and accuracy of various lead screw types commonly used in precision engineering applications. The data showcases linear motion systems' performance metrics, highlighting the difference in efficiency ratings and positioning accuracy between different lead screw configurations.