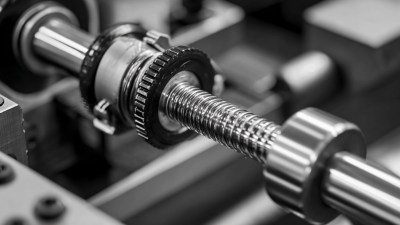

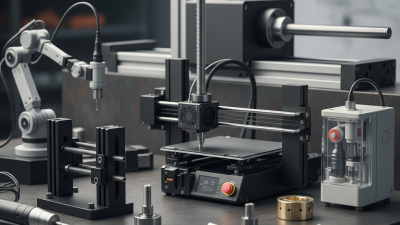

A lead screw is a crucial component in many mechanical systems. It translates rotary motion into linear motion. Lead screws are commonly used in equipment like 3D printers and CNC machines. Their design is simple yet effective, enabling precision control.

The working principle is straightforward. When the screw rotates, a nut moves along its length. This movement is linear and can be easily controlled by adjusting the rotation speed. The lead screw’s pitch determines how far the nut travels with each turn. This relationship affects performance and accuracy.

However, lead screws are not flawless. Over time, wear can affect their efficiency. Issues like backlash can arise, impacting precision. Understanding these limitations is essential for effective use. Lead screws offer a balance between simplicity and functionality, but careful consideration is necessary.

A lead screw is a linear motion component widely used in mechanical systems. It converts rotary motion into linear motion. Typically made of metal, the lead screw features a helical thread running along its shaft. This thread engages with a nut that moves along the screw as it rotates. The accuracy of this movement can be essential for applications, including CNC machines and 3D printers.

Lead screws come with several key characteristics. The lead, or distance the nut moves per revolution, varies. This affects speed and precision. A lead screw’s pitch directly influences the load capacity and efficiency. Reports indicate that lead screws can achieve accuracy levels of up to 0.001 inches under optimal conditions. However, performance can degrade over time due to wear.

**Tip:** Regularly check lead screws for signs of wear or misalignment. This will help maintain performance.

Lead screws also have limitations. They rely on friction between the screw and nut. This can lead to wear, reducing life expectancy. A poor choice of materials can exacerbate this issue. Selecting the right lead screw materials is critical for long-term use.

**Tip:** Always choose high-quality materials to ensure longevity and reliability in your systems.

This bar chart illustrates the efficiency percentages of different lead screw materials commonly used in mechanical systems. The data indicates how each material performs in terms of efficiency, showcasing steel as the most efficient option.

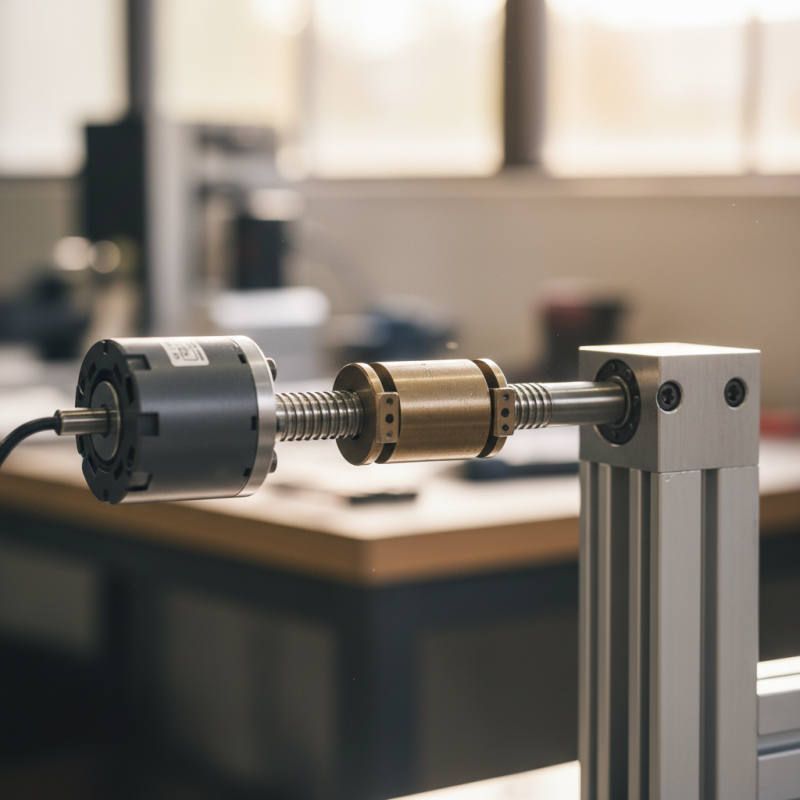

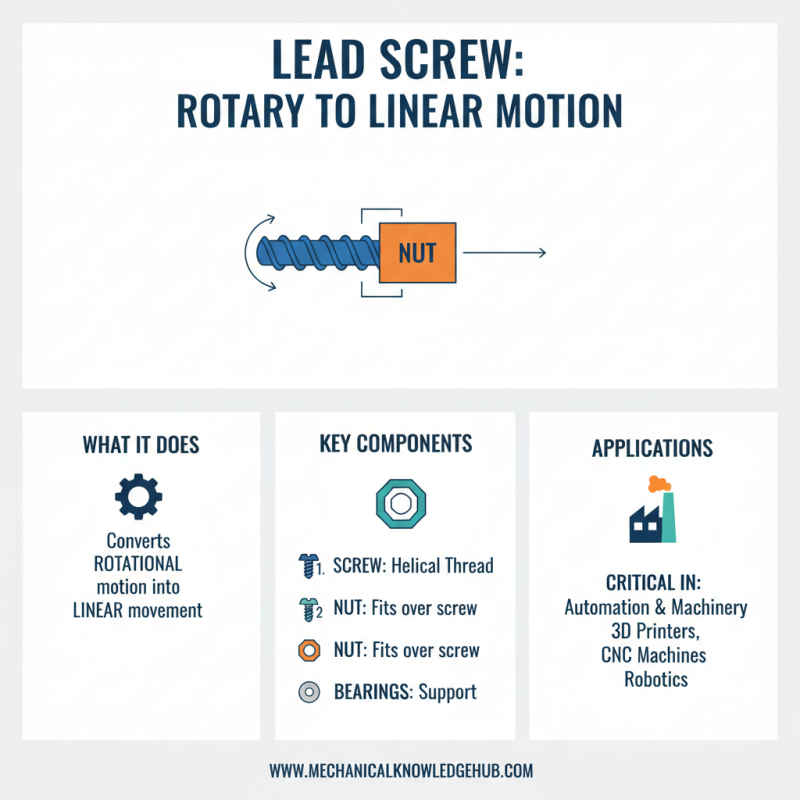

A lead screw is a simple yet effective mechanical component. It converts rotational motion into linear movement. Its assembly includes several key components: the screw, nut, and often bearings. The screw has a helical thread, while the nut fits over it. This basic design plays a critical role in various applications, such as automation and machinery.

The precision of a lead screw assembly relies on its components. The screw's thread type influences the load capacity and efficiency. A trapezoidal thread provides more strength than a square thread but can have more friction. Bearings can minimize friction, enhancing performance. Choosing the correct materials is also vital. Stainless steel offers better durability but can be heavier.

Tips: Always check for wear on both the screw and nut. This will prevent unexpected failures. Regular maintenance helps maintain performance. Alignment is crucial; misalignment can lead to excessive wear. It’s essential to consider the application demands while designing the assembly. Balancing efficiency and strength is not always straightforward. Small adjustments can make a significant impact on the overall functionality.

Lead screws play an essential role in converting rotary motion into linear motion in various mechanical systems. A typical lead screw consists of a threaded shaft and a nut. When the screw rotates, the threads engage with the nut. This interaction causes the nut to travel along the length of the screw. The movement can be precise, but it may not always be smooth. This is due to factors like friction or misalignment.

The efficiency of lead screws heavily relies on their design and materials. For instance, a lead screw with a steep thread angle offers faster linear motion but can generate more wear and tear. A coarser pitch can lead to less precision. In turn, this can create complications in applications requiring high accuracy. It's crucial to choose the right type of lead screw based on specific needs. Despite their benefits, users might overlook maintenance, leading to unexpected failures over time.

Lead screws are widely used in applications like CNC machines and 3D printers. They enable controlled movement in these devices. However, users should regularly inspect the lead screws for wear. Regular checks can help maintain performance and prevent significant downtimes. While lead screws are effective, they are not perfect. Understanding their limitations is essential for optimal use in mechanical systems.

Lead screws are crucial components in many mechanical systems. They convert rotary motion into linear motion, allowing precise control. They are commonly found in applications like 3D printers, CNC machines, and even medical devices. Their simplicity and reliability make them a choice for various industries.

In modern machinery, lead screws facilitate smooth movement and positioning. In robotics, they offer exact control over motion. This precision is vital for tasks requiring careful manipulation. However, lead screws are not without their flaws. They can experience backlash, which affects accuracy. Additionally, they may not be suited for high-speed applications. The trade-offs in lead screw designs challenge engineers to find the right balance.

Another area where lead screws shine is in automation. Conveyor systems utilize them for controlled material handling. Industrial equipment relies on these screws for linear actuation. Yet, maintenance can be an issue. Proper lubrication is essential to avoid wear. Ignoring this can lead to reduced performance. It’s important to regularly check and adjust lead screws to maintain efficiency.

Lead screws are crucial components in many mechanical systems. They convert rotary motion into linear movement. Understanding their performance metrics is essential for effective application. Two key metrics for evaluating lead screws are efficiency and load capacity.

Efficiency defines how much input energy is converted into useful work. Lead screws often show efficiency rates between 30% and 90%. This variation depends on the application and design. For instance, the pitch and material can significantly affect performance. A well-designed lead screw can minimize friction and wear, yet not all designs achieve this.

Load capacity indicates the maximum load a lead screw can handle without failing. It is generally determined by the screw's dimensions and material. Overloading can lead to premature failure. However, many engineers overlook this aspect during design phases. Real-world conditions can alter the expected load significantly. Thus, regular checks and calculations are necessary for ensuring safety and functionality in applications.

| Lead Screw Type | Efficiency (%) | Load Capacity (N) | Pitch (mm) | Diameter (mm) |

|---|---|---|---|---|

| Acme Lead Screw | 80 | 500 | 5 | 20 |

| Ball Screw | 90 | 1000 | 4 | 25 |

| Trapezoidal Screw | 75 | 300 | 6 | 18 |

| Lead Screw with Low Friction | 85 | 800 | 3 | 22 |