Flange bearings are critical components in various machinery, providing crucial support and facilitating smooth movement. As we delve into the intricacies of selecting the right flange bearing for optimal performance, it's essential to consider various factors that influence their functionality. According to John Smith, a renowned expert in the field of bearing technology, "Choosing the right flange bearing can significantly impact not only the efficiency of your equipment but also its longevity." With decades of experience, Smith emphasizes the importance of understanding the specific requirements of your application to achieve the best results.

In this ultimate guide, we will explore essential tips for flange bearing selection, concentrating on key aspects such as load capacity, environmental factors, and installation practices. Each of these elements plays a vital role in ensuring that flange bearings function at their best. Whether you're a seasoned engineer or a newcomer to the industry, having a comprehensive understanding of these selection criteria will empower you to make informed decisions that enhance the performance and durability of your machinery. Let’s embark on this journey to optimize the capabilities of flange bearings in your applications.

Flange bearings are essential components in various mechanical systems, providing support and facilitating rotational motion. Defined as bearings that incorporate a flange, these devices are designed to be mounted on a surface for improved stability and easier alignment. They come in various types, including pillow block, flange mount, and those made from materials ranging from plastic to metal. According to a report by the National Bearings Association, flange bearings account for approximately 22% of all bearing sales globally, reflecting their widespread applicability in industries such as automotive, aerospace, and manufacturing.

Different types of flange bearings are available to cater to specific needs based on load, speed, and environmental conditions. For instance, pillow block bearings are designed for heavy loads and offer excellent durability, while composite flange bearings are favored in applications where corrosion resistance is crucial. The selection process often weighs factors such as the bearing's load rating, as determined by the ABMA (American Bearing Manufacturers Association), which emphasizes the importance of matching the bearing type with operational requirements.

Understanding the intricacies of these bearings and their applications is key to optimizing performance and enhancing the lifespan of machinery, as improper selection can lead to increased wear and maintenance costs.

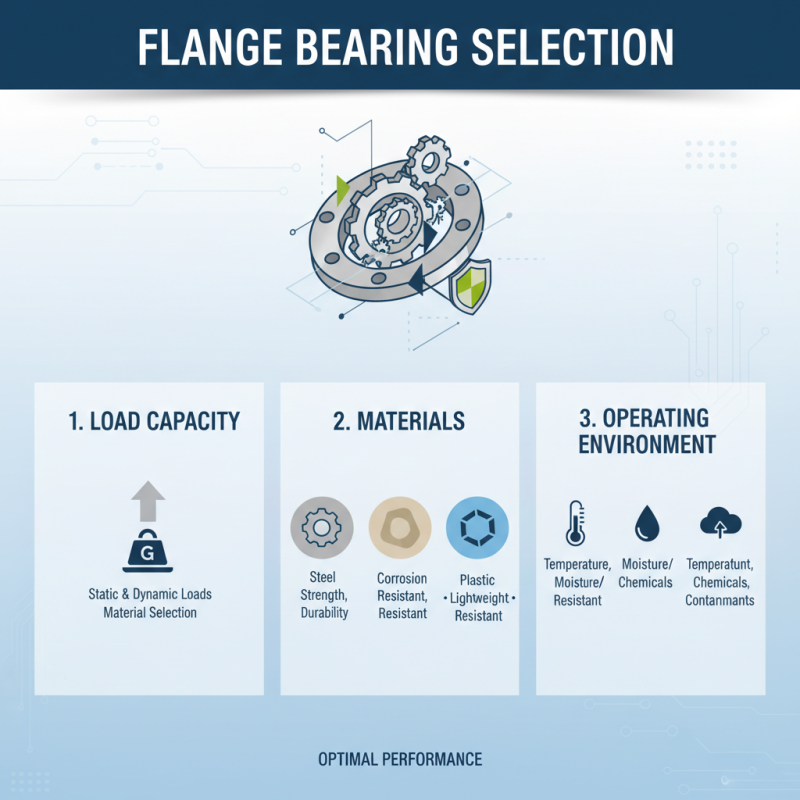

When selecting flange bearings, several key factors should be carefully considered to ensure optimal performance in a given application. One of the most critical aspects is the load capacity of the bearing. Determining the static and dynamic loads that the flange bearing will encounter is essential; this will dictate the selection of materials and dimensional specifications. Common materials include steel, plastic, and bronze, each offering unique advantages in different environments and load scenarios. Understanding the load profile helps engineers choose a bearing that will not only support the required weight but also withstand dynamic forces during operation.

Another significant factor to consider is the operating environment. Conditions such as temperature, humidity, and exposure to chemicals can greatly influence the longevity and functionality of flange bearings. For instance, in high-temperature applications, materials that maintain their integrity under heat must be prioritized. Additionally, contamination from dust or moisture can lead to premature wear, so selecting sealed or shielded bearings might be beneficial in such scenarios. Therefore, assessing the environmental conditions alongside the mechanical demands will lead to a more informed and effective flange bearing selection process.

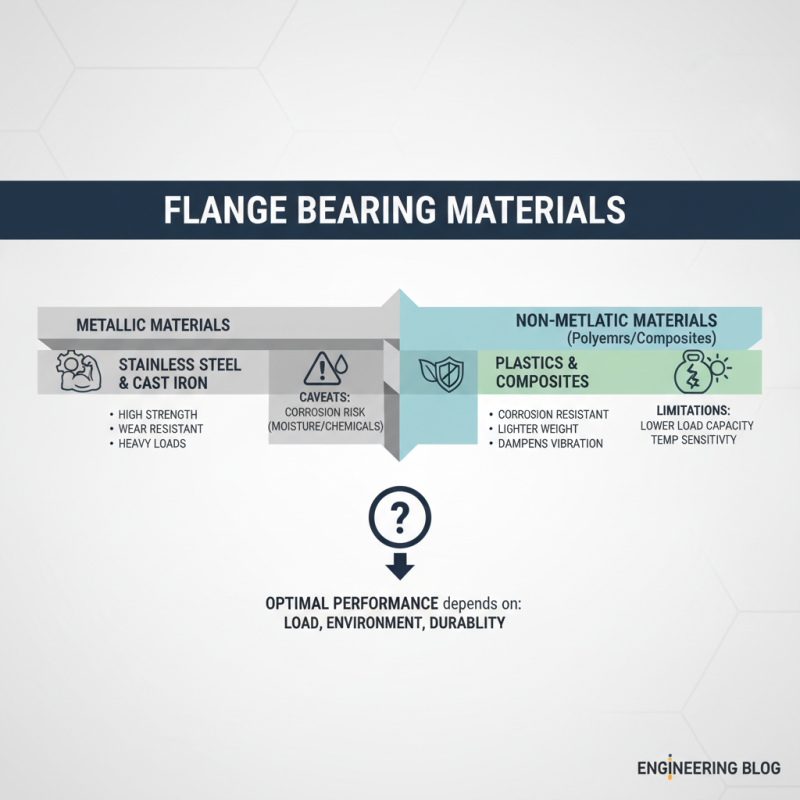

When selecting flange bearings, the choice of material is critical to achieving optimal performance. The material directly influences not only the bearing's load capacity and durability but also its resistance to environmental conditions. For instance, metallic materials such as stainless steel and cast iron offer high strength and excellent wear resistance, making them suitable for heavy-load applications. However, these metals may be susceptible to corrosion if exposed to moisture or harsh chemicals, potentially compromising longevity and reliability.

On the other hand, non-metallic options like polymers or composite materials provide unique advantages, especially in environments where weight reduction and corrosion resistance are paramount. These materials generally exhibit lower friction, which can enhance efficiency and reduce energy consumption. Moreover, many polymers possess inherent damping properties, which can help in noise reduction and vibration absorption. When selecting the appropriate flange bearing material, it is crucial to consider both the operational environment and the specific performance requirements to ensure the best fit for the application.

Flange bearings are integral components in various industries due to their versatility and effectiveness in supporting rotating shafts while reducing friction. A report by the International Journal of Mechanical Engineering highlighted that flange bearings are increasingly employed in automotive applications, where they facilitate the smooth operation of axles and wheels. Additionally, in the manufacturing sector, flange bearings are used in conveyor systems, enabling continuous movement of materials and minimizing downtime. The durability and reliability of these bearings significantly enhance the efficiency and longevity of machinery, leading to reduced operational costs.

In the realm of renewable energy, flange bearings are critical in the functioning of wind turbines. According to a study from the American Society of Mechanical Engineers, the use of high-quality flange bearings can increase the lifespan of turbine components by up to 30%. This improvement not only ensures greater energy output but also contributes to lower maintenance costs, solidifying the role of flange bearings in the push for sustainable energy solutions. Their application in these industries underscores the importance of selecting the right type for specific operational conditions, thereby optimizing performance and reliability in demanding environments.

| Application | Common Materials | Load Capacity (lbs) | Speed Ratings (RPM) | Typical Temperature Range (°F) |

|---|---|---|---|---|

| Automotive | Steel, Plastic, Bronze | 3000 | 2000 | -30 to 200 |

| Manufacturing Equipment | Aluminum, Stainless Steel | 4500 | 3000 | -20 to 180 |

| Aerospace | Titanium, Composite Materials | 2000 | 15000 | -50 to 350 |

| Food Processing | 316 Stainless Steel, PTFE | 2500 | 1800 | 0 to 250 |

| Construction Equipment | Cast Iron, Steel | 5000 | 1200 | -20 to 150 |

Maintaining flange bearings is crucial for ensuring their longevity and optimal performance. Regular maintenance practices can significantly extend the life of these components, reducing the risk of premature failure. One of the fundamental best practices is to keep the bearings clean and free from contaminants. Dirt and debris can accelerate wear and tear, leading to malfunction. Regularly inspect the surrounding area and ensure that seals and shields are in place to protect the bearings from exposure to harmful particles.

Another essential tip is to monitor lubricant levels and quality. Proper lubrication reduces friction and heat buildup, which are critical factors in flange bearing performance. Use the recommended lubricant type and replace it according to the manufacturer's guidelines to maintain smooth operation. Additionally, consider the operating environment; extreme temperatures or heavy loads may necessitate more frequent lubrication to maintain effectiveness.

Finally, implement a regular inspection schedule to check for signs of wear, such as unusual vibrations or noises. Early detection of potential issues can help mitigate more significant problems down the line. Following these maintenance best practices will ensure your flange bearings perform optimally and last longer, contributing to the overall efficiency of your machinery.