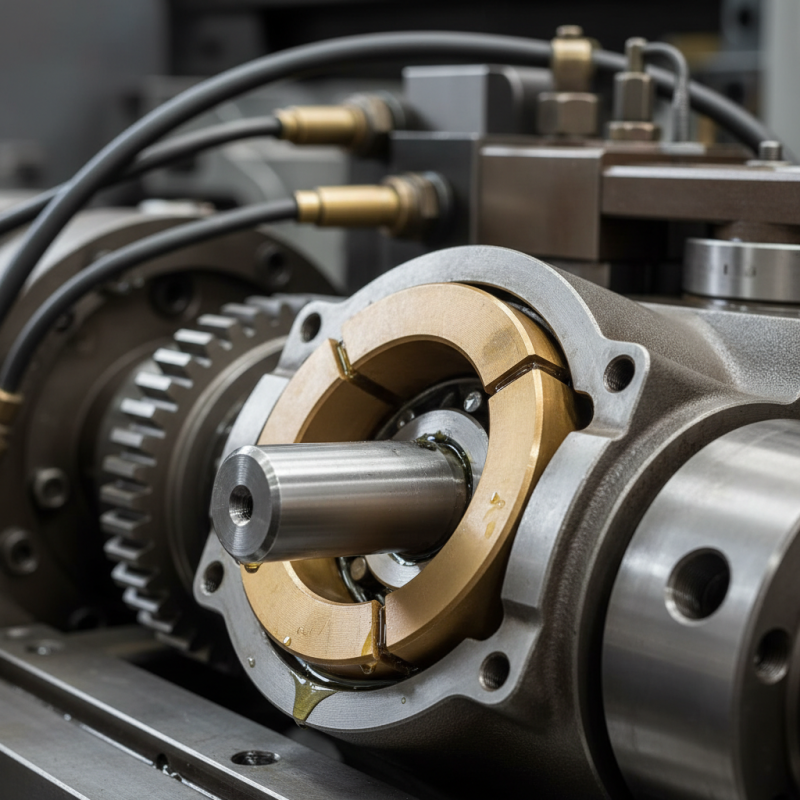

In the world of engineering, bronze bushings stand out as a crucial component. Industry reports indicate that over 60% of machinery failures are linked to inadequate lubrication. Bronze bushings significantly reduce friction, thereby enhancing performance and longevity.

For instance, in demanding applications such as automotive and aerospace, the durability of bronze bushings is essential. They offer remarkable resistance to wear and corrosion. According to a 2022 study by the Machinery Research Institute, bronze bushings can last up to five times longer than plastic alternatives.

However, not all bronze bushings are created equal. The quality of the material plays a critical role. Engineers must carefully select the appropriate grade and sizing to avoid costly downtime. Additionally, failures can result from improper installation, which often goes unnoticed until damage occurs. Recognizing these challenges is vital for maximizing the benefits of bronze bushings in engineering applications.

Bronze bushings play a crucial role in engineering applications. They are widely used due to their excellent anti-friction properties. According to industry reports, bronze bushings reduce wear and prolong the lifespan of machinery. Their ability to withstand heavy loads makes them ideal for various applications. These bushings can handle a wide range of temperatures, further enhancing their utility.

Many engineers prefer bronze for its low coefficient of friction. Studies indicate that using bronze bushings can improve productivity by up to 30%. This improvement can lead to significant cost savings over time. However, one should consider the initial costs associated with bronze bushings. They can be higher than plastic or steel alternatives. Maintenance practices also require careful planning. In some cases, maintenance schedules can get overlooked, leading to premature failures.

The benefits of bronze bushings are clear, yet there are challenges. Not all projects require such materials. For lighter applications, alternatives may suffice. Understanding when to use bronze bushings takes experience. Engineers must balance cost against performance needs in their designs. This reflective approach is key to effective engineering practices.

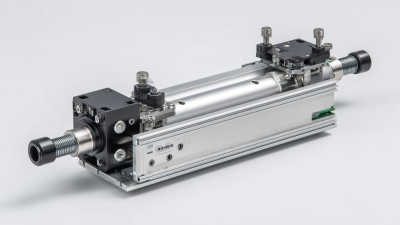

In high-stress applications, bronze bushings stand out for their remarkable durability and longevity. The unique properties of bronze make it a preferred choice in engineering. Its inherent strength allows it to withstand heavy loads without compromising performance. This is especially crucial in machinery where failure can lead to significant downtime and costly repairs.

Bronze bushings resist wear and tear, extending the lifespan of components. They perform well in harsh environments, where moisture and debris are common. Their self-lubricating nature reduces friction and minimizes maintenance needs. Yet, it’s important to recognize that installing bronze bushings requires precision. Improper fitting can lead to premature wear, a daunting challenge for engineers.

Moreover, while bronze exhibits excellent resistance to corrosion, it is not invincible. In some extreme conditions, it can degrade over time. Engineers must evaluate these factors carefully. Balancing the advantages with potential drawbacks is vital for optimal performance in engineering applications. The road to efficiency often requires thoughtful consideration of material choices, strategies, and the environment in which components operate.

Bronze bushings are fundamental components in engineering, providing numerous advantages in demanding applications. The chart above highlights the top benefits of using bronze bushings, showcasing their durability, resistance to wear and corrosion, and overall value in high-stress environments.

Bronze bushings are increasingly popular in various engineering applications. Their unique properties provide outstanding wear resistance. They help reduce friction and extend the lifespan of machinery. A study by the American Society of Mechanical Engineers indicates that systems using bronze bushings have improved durability by up to 40%. This is particularly vital in industries where equipment faces extreme conditions.

The friction generated in conventional metal components can lead to rapid wear. Bronze bushings, however, offer a smoother surface. This reduces heat generation while operating. According to the National Lubricating Grease Institute, bronze bushings minimize the coefficient of friction by approximately 60%, making them efficient choices for high-performance contexts. The result is often a notable decrease in maintenance costs, with estimates showing savings of up to 30% over time.

Incorporating bronze bushings can lead to unexpected challenges. Some engineers may overlook compatibility issues with other materials. Not every application suits bronze. When used incorrectly, the benefits can diminish quickly. This requires engineers to carefully analyze their designs, weighing the benefits against potential drawbacks. A balanced approach ensures optimal performance and longevity.

Bronze bushings are known for their cost-effectiveness in engineering applications. The initial investment may appear substantial, but their long lifespan reduces replacement frequency. This can significantly lower maintenance costs over time. A study by the ASTM revealed that bronze components can last up to five times longer than plastic alternatives. This longevity translates into fewer downtime periods, benefiting production schedules.

When considering economic factors, bronze bushings demonstrate impressive wear resistance. A recent report indicated that they reduce wear by approximately 50% compared to other materials. This durability means fewer resources spent on replacements and repairs. However, it's crucial to balance investment costs with long-term benefits. Some companies might hesitate, perceiving the upfront cost as a hindrance.

Yet, the operational efficiency gained from using bronze bushings often outweighs initial expenses. Their ability to maintain performance under stress is undeniable. Some users report an increase in machinery efficiency by up to 20%. Nevertheless, not all projects may justify this choice. Analyzing specific engineering needs is vital to ensure maximum value. Not every scenario calls for bronze, and understanding project demands is key to making the right decision.

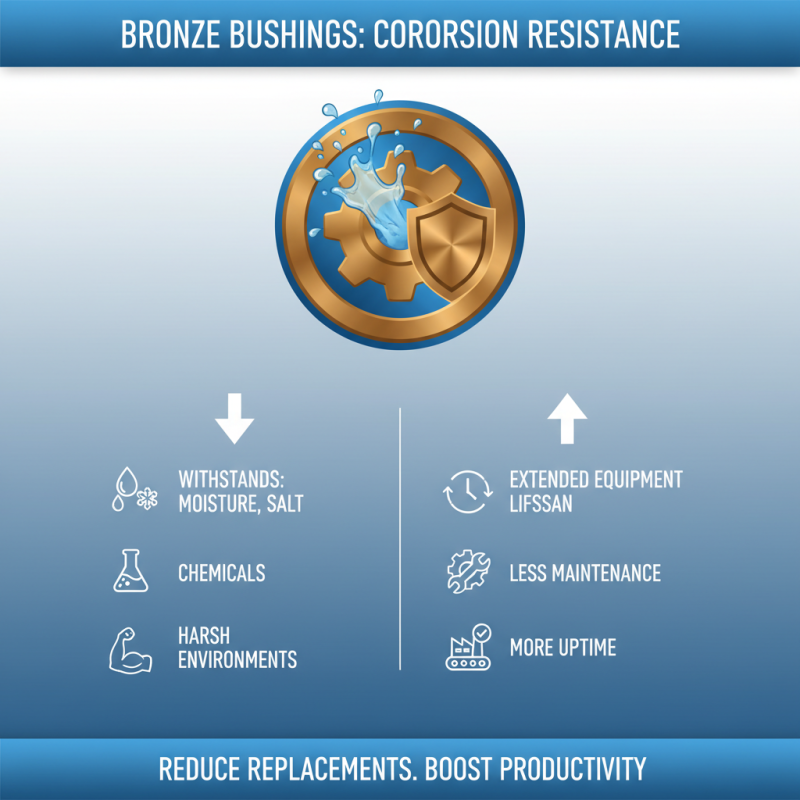

In harsh environments, corrosion poses a significant threat to machinery and components. Bronze bushings offer exceptional corrosion resistance. They withstand moisture, salt, and even chemicals. This ability extends the lifespan of equipment, reducing the need for frequent replacements. Less maintenance means more uptime for production lines.

Bronze is a versatile material. It often features a blend of copper and tin. This combination improves durability against wear and tear. Interestingly, even with its strong resistance, bronze isn't immune to corrosion in extreme cases. Regular inspections remain essential. Depending on the environment, some users may overlook subtle signs of degradation.

When choosing bushings, one must consider the specific application. The advantages are clear, but challenges exist. Factors like temperature fluctuations can influence performance. Maintaining a balance between cost and quality can be tricky, requiring careful thought.