As the demand for automation continues to grow across various industries, electric actuators have emerged as essential components for modern systems. These devices play a crucial role in converting electrical energy into mechanical motion, allowing for precise control over a wide range of applications, from industrial machinery to home automation. Understanding the key features and functionalities of electric actuators is vital for consumers looking to invest in these innovative solutions, especially as we approach 2025.

In this comprehensive guide, we will explore the top electric actuators available on the market, highlighting their key features, advantages, and considerations to keep in mind when making a purchase. Whether you are an engineer, a DIY enthusiast, or simply interested in enhancing your home with automation technology, having a thorough understanding of electric actuators will empower you to make informed decisions. By focusing on the latest advancements and trends in electric actuator technology, this guide aims to equip consumers with the knowledge necessary to navigate their options and select the best solutions for their specific needs.

Electric actuators have evolved significantly by 2025, offering advanced features that enhance their efficiency and effectiveness in various applications.

One of the key features to consider is precision control. Modern electric actuators provide exceptional accuracy, allowing for precise positioning and movement that is crucial in automation processes. This is especially beneficial in sectors like manufacturing and robotics, where even the slightest deviation can result in operational failures.

Another important feature is energy efficiency. As industries are increasingly focused on sustainable practices, electric actuators designed for 2025 are optimized to consume less power while delivering robust performance. This not only reduces operational costs but also minimizes the environmental impact.

Tips: When choosing an electric actuator, consider the torque requirements for your specific application to ensure optimal performance. Additionally, look for models with programmable features that can adapt to various tasks or conditions, enhancing versatility and user convenience. Lastly, always check for compatibility with your existing systems to avoid integration issues.

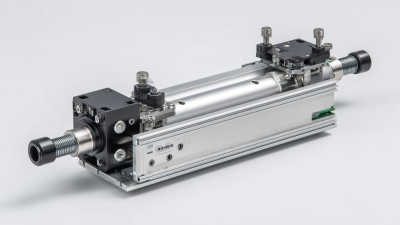

Electric actuators are essential components in various industrial and consumer applications, providing precise control over mechanical movements. There are several types of electric actuators, each designed to suit specific tasks and environments. The most common types include linear actuators, which convert electrical energy into linear motion, and rotary actuators, which produce rotational motion. Linear actuators are often used in applications such as conveyor systems, automated doors, and valve control, while rotary actuators are ideal for applications that require turning or positioning, such as robotics and automated machinery.

In addition to linear and rotary actuators, there are also specialized types like piezoelectric actuators that utilize the piezoelectric effect to achieve incredibly precise movements. These are often found in medical devices, optics, and scientific instruments where accuracy is paramount. Another variation is the actuator with integrated feedback systems, which enhance performance by providing real-time position data. This adaptability makes electric actuators crucial in industries ranging from manufacturing and aerospace to automotive and home automation, where efficiency and control are prioritized. Understanding these types and their applications can guide consumers in selecting the right electric actuator for their specific needs.

When choosing the right electric actuator, consumers should first consider the specific application requirements. Understanding the load characteristics, such as weight and resistance, is crucial since it determines the type and size of the actuator needed. Additionally, the stroke length must be compatible with the mechanical system it will operate within. These factors help in ensuring that the actuator not only fits but also performs optimally in its designated role.

Another key consideration is the operating environment. Electric actuators can be affected by temperature, humidity, and potential exposure to corrosive substances. Selecting an actuator designed to withstand these environmental conditions will enhance durability and reliability. Moreover, consumers should evaluate the control options available, as modern electric actuators may offer advanced features such as programmable settings, feedback mechanisms, and connectivity for integration into automated systems. By carefully assessing these aspects, consumers can make informed purchasing decisions that align with their needs.

This chart illustrates the performance metrics of top electric actuators available in 2025. Metrics include torque, speed, voltage, load capacity, and control accuracy.

Electric actuators have become indispensable in various industrial applications, and their performance can be influenced by several critical factors. One of the primary aspects is the actuator's design and construction, which entails the type of materials used, the precision of the motor, and the overall architecture. High-quality materials can enhance durability and performance, while precision-engineered components lead to improved response times and accuracy. According to a report by ResearchAndMarkets, the global market for electric actuators was valued at approximately $10.1 billion in 2021 and is expected to grow at a CAGR of 6.3% through 2026, indicating a rising demand largely driven by advancements in actuator technology.

Another significant factor affecting electric actuator performance is the operating environment. Conditions such as temperature, humidity, and exposure to corrosive substances can greatly impact the efficiency and lifespan of these devices. For instance, actuators employed in harsh environments may require specialized coatings or enclosures to protect against wear and tear, as evidenced by findings from a 2022 industry analysis that noted a 20% decrease in actuator life expectancy when subjected to extreme temperatures without adequate protection. Thus, understanding these influencing factors is essential for consumers looking to make informed choices when selecting electric actuators for their specific applications.

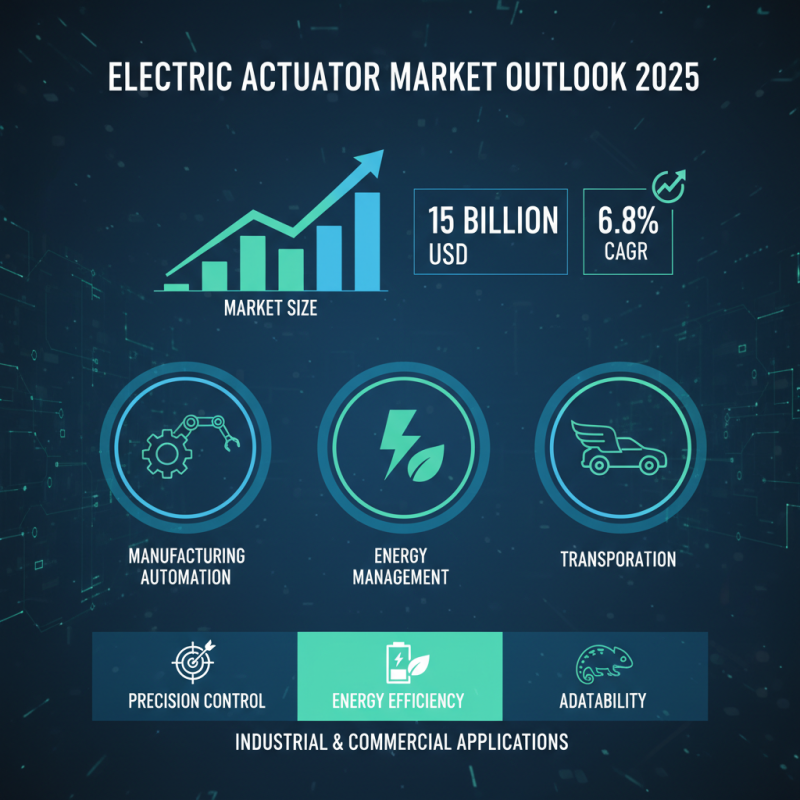

In 2025, the electric actuator market is anticipated to witness significant growth, driven by increasing demand across various sectors, including automation in manufacturing, energy management, and transportation. According to a recent industry report, the global electric actuator market size is projected to reach approximately $15 billion by 2025, reflecting a compound annual growth rate (CAGR) of around 6.8%. Key features that consumers should consider include precision control, energy efficiency, and adaptability to different environments, making them ideal for both industrial and commercial applications.

Among the leading models, several brands are noted for their innovation and reliability. Electric actuators are designed with advanced technologies such as feedback control systems, which enhance their responsiveness and accuracy in applications ranging from robotics to HVAC systems. Additionally, many of the top models now offer connectivity options, enabling integration into smart automation ecosystems. Features like built-in diagnostic capabilities are increasingly common, allowing users to monitor performance and reduce maintenance costs effectively. The emphasis on sustainability is also raising the profile of models incorporating eco-friendly designs and energy-saving features, catering to a wide array of consumer preferences and regulatory requirements.