In the realm of engineering and manufacturing, the selection of materials significantly impacts the performance and longevity of mechanical components. Among these critical materials, bronze bushings stand out for their exceptional wear resistance, load-bearing capacity, and corrosion resistance. According to the latest market research report by Smithers Pira, the demand for bronze bushings is expected to rise by 5.3% annually through 2025, driven by their application in high-performance machinery across various industries, including automotive, aerospace, and heavy machinery.

Bronze bushings, with their excellent tribological properties, provide a reliable solution to reduce friction and minimize wear in rotating shafts and reciprocating engines. The International Journal of Advanced Manufacturing Technology highlights that proper selection and maintenance of bronze bushings can enhance machinery efficiency by up to 30%, contributing to improved operational productivity and reduced downtime. Understanding the intricacies of bronze bushing selection is thus crucial for engineers aiming to optimize performance and durability in their designs.

As industries continue to prioritize sustainability and cost-effectiveness, the focus on high-quality bronze bushings as a key component in machinery design has never been clearer. This guide aims to provide a comprehensive overview of the best practices for choosing bronze bushings, ensuring that engineers are equipped with the necessary knowledge to achieve optimal performance while maintaining the durability of their applications in the coming years.

In 2025, high-quality bronze bushings are characterized by their superior resilience and enhanced performance, making them essential for various mechanical applications. One of the top characteristics to look for is the bushing's material composition; premium alloys often integrate lead and tin, providing excellent wear resistance and reducing friction during operation. Additionally, hydrostatic lubrication properties are crucial. Bushings that allow for better lubricant retention extend the lifespan of both the bushing and the equipment it supports.

Another significant feature is the precision manufacturing process. High-quality bronze bushings should undergo rigorous quality control to ensure accurate dimensions and tolerances. This precision helps maintain the alignment and effectiveness of the machinery, leading to improved efficiency and reduced maintenance costs. Furthermore, consideration for operating conditions—including temperature fluctuations and load-bearing capacity—is crucial. Bushings that can withstand extreme conditions often offer better durability, maintaining performance even in demanding environments. Overall, these characteristics not only enhance the functionality of machinery but also contribute to a longer service life for critical components.

When it comes to manufacturing bronze bushings, understanding key processes is essential for achieving optimal performance and durability. One of the most significant innovations in this area is the adoption of advanced casting techniques, which enhance the bushing’s mechanical properties and surface finish. Such techniques not only minimize waste but also allow for more precise control over the alloy composition, resulting in components that are more resilient to wear and can withstand extreme conditions.

Another crucial aspect of manufacturing bronze bushings is the implementation of modern machining methods. CNC (Computer Numerical Control) machining has revolutionized the production process, enabling manufacturers to produce high-precision bushings with consistent quality. This technology reduces lead times and allows for greater customization in design, catering to specific applications. Moreover, surface treatments, such as coating and polishing, are increasingly utilized to improve corrosion resistance and reduce friction, further extending the lifespan of the bushings. As these innovations continue to evolve, they are set to redefine industry standards, ensuring that bronze bushings meet the demanding requirements of various applications.

| Dimension | Material Composition | Manufacturing Process | Load Capacity (kg) | Temperature Resistance (°C) | Lifespan (hours) |

|---|---|---|---|---|---|

| 10 mm ID x 20 mm OD x 5 mm | CuSn6 | Casting | 500 | 150 | 2000 |

| 15 mm ID x 30 mm OD x 8 mm | CuSn8 | Extrusion | 1000 | 180 | 2500 |

| 20 mm ID x 40 mm OD x 10 mm | CuSn10 | Forging | 1500 | 200 | 3000 |

| 25 mm ID x 50 mm OD x 12 mm | CuSn12 | Machining | 2000 | 220 | 3500 |

When selecting bronze bushings for optimal performance, understanding the metrics of durability and wear resistance among different bronze alloys is crucial. According to a report by the American Bronze Association, alloys such as C93200 bearing bronze exhibit exemplary wear resistance, with a wear rate reduction of up to 30% compared to lower-grade alternatives. This remarkable attribute allows for extended life spans in high-load applications, which is particularly advantageous in industrial machinery and automotive components.

Further analysis reveals that the tensile strength of bronze alloys significantly influences their overall durability. Alloys like C95400 and C38500 have shown tensile strengths exceeding 70,000 psi, making them exceptional choices for applications requiring robust resistance to deformation and fatigue. Furthermore, a recent study published in the Journal of Materials Engineering indicated that the addition of tin in bronze compositions can enhance wear resistance by up to 25%, making it an optimal choice for environments subject to abrasive wear. By carefully selecting the right bronze alloy, engineers can significantly improve component longevity and reduce maintenance costs.

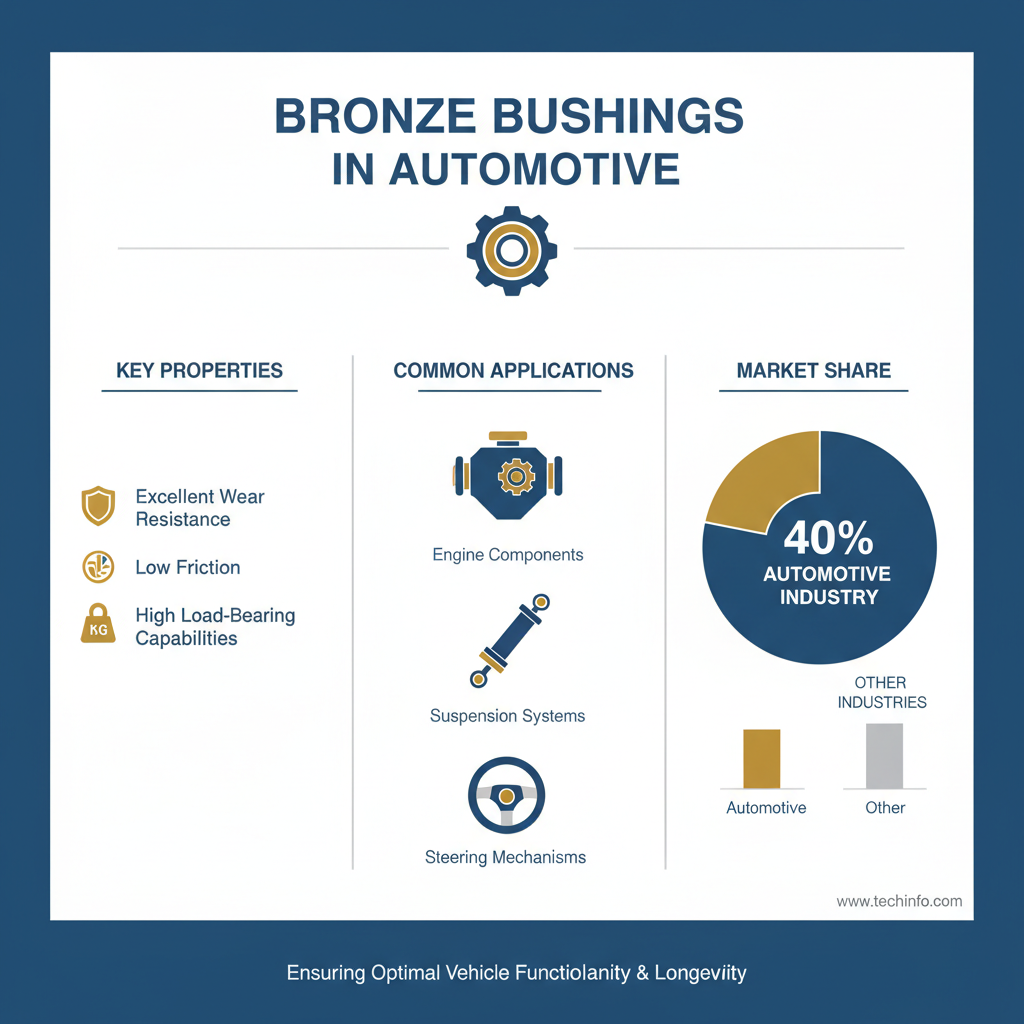

Bronze bushings are widely utilized across various industries due to their unique properties, such as excellent wear resistance, low friction, and high load-bearing capabilities. In the automotive sector, they are commonly found in engine components, suspension systems, and steering mechanisms, where the durability and performance of parts under stress are crucial. Statistical data indicates that the automotive industry accounts for approximately 40% of the global bronze bushing market, highlighting the material's significance in ensuring optimal vehicle functionality and longevity.

In addition to automotive applications, bronze bushings play a critical role in manufacturing and machinery. Industries such as aerospace, construction, and heavy equipment rely heavily on these components to enhance operational efficiency and reduce maintenance costs. Recent studies show that the industrial machinery sector represents around 30% of the bronze bushing usage, primarily due to the material's ability to withstand harsh environments.

Furthermore, the growing demand for renewable energy solutions, including wind turbines, has further bolstered the market, as bronze bushings provide reliable performance in demanding conditions. This statistical overview underscores the versatility and importance of bronze bushings in ensuring optimal performance across various sectors.

Maintaining bronze bushings is crucial for ensuring optimal performance and longevity in various applications. According to a report by the American Society of Mechanical Engineers (ASME), proper maintenance practices can extend the life of bronze bushings by up to 30%. This is particularly important in industries such as manufacturing and transportation, where the cost of equipment downtime can be substantial. Regular inspection and timely lubrication significantly reduce wear and tear, ultimately enhancing operational efficiency.

One best practice for maintaining bronze bushings involves utilizing the correct lubricant. A study published in the Journal of Manufacturing Processes highlights that using high-quality, low-viscosity lubricants can decrease friction and heat generation, which are common causes of premature failure. Additionally, maintaining optimal working conditions, such as avoiding exposure to contaminants and ensuring proper alignment, can further prolong the life of bushings. It is essential that industries adopt these best practices to maximize the performance of bronze bushings and achieve greater durability in their applications.

This chart illustrates the key performance metrics for bronze bushings in 2025, focusing on lifespan, load capacity, friction factor, and temperature resistance. Understanding these metrics can help in selecting the right bronze bushing for optimal performance and durability.