What is a pillow block bearing?

Bearings are a staple (and necessity) in industrial applications across all industries. Pillow block bearings stand out as a specialized type of bearing that combines a bearing and housing, providing support and alignment to rotating shafts.

Read on to learn all about pillow block bearings, from their design and various types to the materials that make them indispensable in mechanical designs.

What is a pillow block bearing?

A pillow block bearing (sometimes referred to as plummer block bearings) is a type of mounted bearing contained within a supportive housing. Its primary purpose is to provide smooth rotation of a shaft while maintaining proper alignment and withstanding the load.

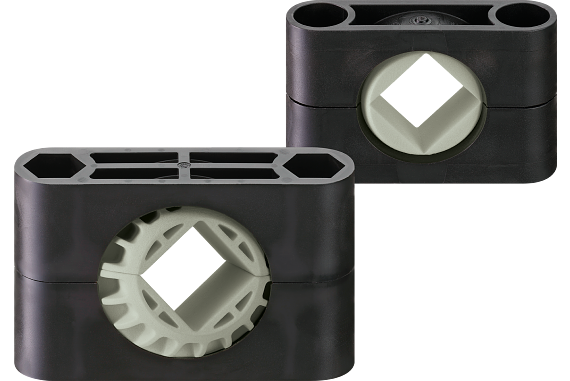

Pillow block bearings are easy to install, maintain, and replace, offering a stable platform for rotating components. They’re made up of three primary components:

- Inner bearing: This core component can be a ball, roller, or other bearing type, depending upon the specific application.

- Housing or block: This “pillow” structure secures the bearing and allows it to be bolted to a surface, such as a machine frame.

- Seals and shields: Some pillow block bearings include protective seals or shields to guard against dirt, dust, and moisture, ensuring durability and reliability.

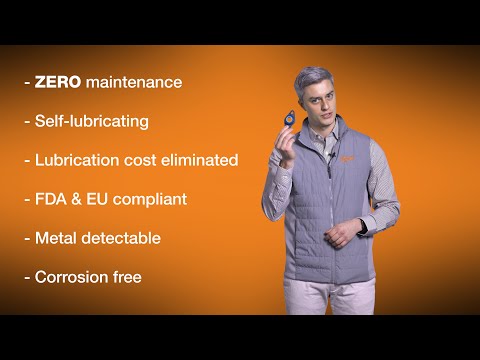

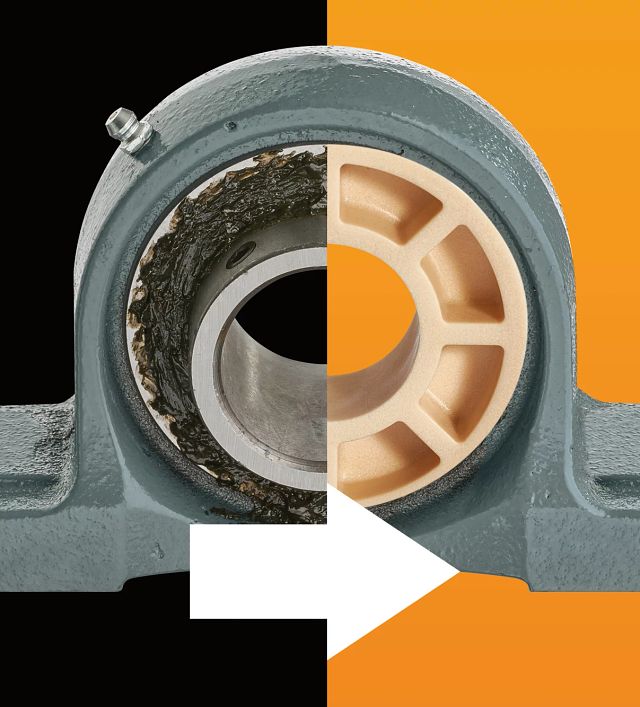

Note: Self-lubricating plastic pillow block bearings — like those available from igus — do not require the use of a seal or shield, as they inherently resist dirt and dust due to grease-free operation.

How do pillow block bearings work?

As the shaft rotates, the balls or rollers inside the bearing — or the bearing itself — reduce friction, enabling smooth movement. The surrounding pillow block holds the bearing securely in place, minimizing vibrations and keeping the shaft aligned, even under dynamic conditions. This combination ensures both stability and longevity even in harsh conditions and heavy use.

Related: An Introduction to Self-Aligning Plain Bearings

Applications of pillow block bearings

Due to their versatility, pillow block bearings are used across numerous industries where rotating components require support. Below are a few examples.

Industrial applications

Pillow block bearings are ideal in conveyors, material handling systems, and similar packaging automation due to their ability to maintain roller and belt alignment. This ensures wear is minimized and continuous operation can be maintained. Other industrial applications such as textile machinery benefit from pillow block bearings, which support rotating components in looms and spinning machines.

Agricultural equipment

Used in machines like harvesters, plows, and seeders, where they support shafts and axles under heavy loads. Their robust design helps resist contaminants such as dirt and moisture, along with the heavy loads found in these applications, making them ideal for these challenging applications.

Automotive applications

Most often found in engine components such as belt drives and alternators, pillow block bearings maintain smooth, consistent rotation. In some cases, they are also used in suspension systems to support dynamic shafts.

Construction and heavy-duty equipment

Pillow block bearings play a vital role in heavy-duty equipment by enhancing performance and reducing energy consumption. In pumps, fans, and motors, they ensure proper shaft alignment, thereby lowering energy use, while in mixers, crushers, and mills, they withstand heavy loads and vibrations, supporting machinery performance in harsh environments.

Advantages of insert pillow block bearings

Many different types of pillow block bearings exist, including ball, spherical roller, tapered roller, and cylindrical roller pillow block bearings. However, in most applications, plastic insert pillow block bearings offer advantages that can’t be matched by the alternatives.

Using insert pillow block bearings allows for compensation of slight misalignment of the shaft, leaving more room for error and helping to ensure optimal performance. While other pillow block bearings such as spherical rollers can also achieve this, plastic inserts don’t require frequent and costly relubrication, and instead run completely dry.

Using dry-running, tribologically optimized plastics offers a number of other advantages over metal bearings, including resistance to dirt, dust, corrosion, and UV exposure, lightweight composition, cost-savings, and vibration damping properties.

Common materials used in pillow block bearings

The performance, durability, and environmental resistance of pillow block bearings depends on the materials used for both the bearing and housing.

Cast iron

- Why it’s used: Strong, durable, and capable of withstanding heavy loads.

- Applications: Common in industrial machinery, conveyors, and farming equipment.

Stainless steel

- Why it’s used: Resistant to corrosion, making it ideal for wet or chemically exposed environments.

- Applications: Food processing equipment, marine machinery, and chemical plants.

Zinc alloy

- Why it’s used: Provides corrosion resistance at a more affordable cost compared to stainless steel, albeit with less strength.

- Applications: Small motors and other light-duty equipment exposed to moisture.

Bronze

- Why it’s used: Can handle high loads at low speeds and offers excellent wear resistance, but requires frequent greasing to maintain optimal performance.

- Applications: Cranes, lifts, and heavy equipment that operate under harsh conditions.

Plastic composites

- Why it’s used: Lightweight, non-corrosive, and resistant to chemical exposure. Some plastics also offer self-lubricating and maintenance-free operation.

- Applications: Medical devices, pharmaceutical equipment, food and beverage processing.

Conclusion

A well-chosen pillow block bearing can enhance the performance and longevity of your equipment, making it a critical investment for engineers and maintenance teams. When machinery performs at its best, downtime and maintenance costs are reduced.

With this blog, you should now have a deeper understanding of pillow block bearings, their types, and how they serve different industries. Whether you’re maintaining existing equipment or designing new machinery, these bearings are an essential part of keeping things moving smoothly.