7 Guidelines for Continuous Flex Cables

For dynamic applications, the use of continuous-flex cables, such as the chainflex® cable range from igus®, can increase service life and productivity dramatically when compared to traditional cables, which are prone to failures such as corkscrewing, shield/conductor breakage, or jacket abrasion and/or splitting.

In this guide, learn the seven key design features that can ensure a continuous-flex cable will work for your application for millions of cycles — even in the most demanding environments.

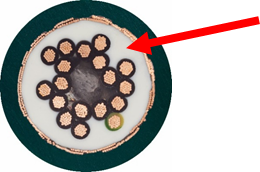

1. Strain-relieving center element

The center core should be filled with a high-quality, high tensile strength center element to protect twisted conductors from falling into the center of the cable.

2. Conductor structure

The copper stranding in chainflex continuous-flex cables is chosen in accordance with tested and proven designs. The test results from the igus lab indicate that a medium to fine conductor strand diameter is preferable. Many competitive cable manufacturers will employ an extra-fine conductor strand, which has the tendency to kink when subjected to a high number of cycles.

Related: Why are cable conductors made of copper?

Using findings from long-term cable testing, igus uses a combination of conductor strand diameter, pitch length, and pitch direction to achieve the best service life and performance, eleven in the most demanding applications.

3. Conductor insulation

Insulation materials within the cable must be resistant to adhering to one another. The insulation must also support the stranded individual sides of the conductor. Only the highest quality high-pressure extruded PVC or TPE materials should be used.

4. Cable core

Individual conductors are bundled into groups, which are cabled together in a single layer surrounding the cable core. This design enables pulling and compressive forces if the bending motion to balance and cancel out torsional forces. Special attention is given to pitch length and direction. The cable’s inner jacket will also help to maintain the integrity of the cable core and provide a continuous surface for the shield.

5. Inner jacket

A pressure-extruded inner jacket should be used for cables subjected to continuous flexing, as opposed to inexpensive fleece wrap or filler. This extruded inner jacket ensures that the insulated conductors are efficiently guided, while maintaining the integrity of the cable core and providing a continuous surface for the overall shield.

6. Shield design

A high-quality braided shield provides electromagnetic interference (EMI) protection for the cable. An optimized braid angle prevents the shield strands from breaking over the linear axis and increases torsional stability. The shield has an optical coverage of approximately 90%, providing maximum shield effectiveness.

Related: Why is cable shielding necessary?

7. Outer jacket

The outer jacket material must be resistant to UV radiation, abrasion, oils, and chemicals, as well as being cost-effective. However, the outer jacket of a cable for dynamic applications must be resistant to abrasion, and remain flexible while providing support. For the best wear rates and service life, the outer jacket should be extruded under pressure.

When you implement a continuous-flex cable designed with each of these guidelines in mind, you can dramatically increase the service life of your machine, and reduce the risk of unexpected downtime due to cable failures.