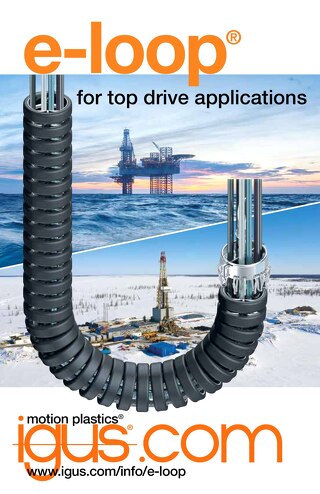

Seadrill enhances operational reliability with igus’ e-loop system

Operating in one of the most demanding environments on the planet, Seadrill, a global leader in offshore drilling, relies on robust technology to ensure operational efficiency and safety. Recognizing the challenges posed by traditional service loops in top drive systems, the company turned to igus® for a cutting-edge solution: the e-loop® e-chain® system. The e-loop, designed to meet the extreme demands of offshore applications, has revolutionized Seadrill's approach to cable management, significantly enhancing reliability and reducing maintenance requirements.

Overcoming offshore challenges

Offshore drilling environments expose equipment to constant vibration, impacts, and extreme weather conditions. Traditional service loops, commonly used in top drive systems, often encounter challenges such as swinging cables, high strain, and limited durability. These issues can result in frequent downtime and increased maintenance efforts, leading to costly operations for companies like Seadrill.

To address these challenges, igus developed the e-loop, an innovative modular energy chain system. This system combines the flexibility of a polymer energy chain with the strength of a high-performance composite rope. The e-loop's design ensures that all forces are absorbed by the rope, effectively relieving cables from strain. As a result, this capability extends the service life of cables and ensures uninterrupted operations in harsh offshore environments.

A Customized Solution for Seadrill's Top Drives

igus worked closely with Seadrill to integrate the e-loop system into their top drive applications. The system's key features include:

Strain Relief and Stability: The composite rope at the core of the e-loop is 15 times stronger than steel, ensuring high load-bearing capacity and stable performance. This prevents cable damage caused by excessive strain.

Weather Resistance: Built from UV- and chemical-resistant materials, the e-loop performs reliably in extreme conditions, including arctic cold and desert heat.

One-Loop Approach: Combines multiple power, signal, and hydraulic loops into a single e-loop, reducing the overall footprint—while at the same time, its compact structure and small bend radius make it ideal for limited spaces and easier for the driller to monitor.

Ease of Maintenance: The modular design allows cables to be accessed, replaced, or maintained individually without dismantling the entire system. This results in significant time and cost savings during rig moves and maintenance operations.

Proven Performance Through Rigorous Testing

To ensure reliability, igus subjected the e-loop system to a series of extensive outdoor endurance tests. In simulated top drive conditions, the system achieved 170,000 cycles in all weather conditions, resulting in no effect on the function of the e-loop. This level of performance gave Seadrill the confidence to implement the e-loop on a second drill ship, replacing traditional service loops and reducing unexpected downtime.

Comprehensive Support and Seamless Integration

igus provided Seadrill with tailored support throughout the implementation process, from system design to on-site installation. The e-loop was delivered as a ready-to-install solution, significantly reducing installation time. Additionally, the use of chainflex® cables ensured optimal performance and cost savings through reduced maintenance and extended durability.

Building a Reliable Future in Offshore Drilling

By adopting the e-loop e-chain system, Seadrill has optimized its top drive operations and set a benchmark for innovation in offshore drilling. The collaboration between Seadrill and igus exemplifies how tailored engineering solutions can address specific industry challenges, driving efficiency and reliability in the most demanding environments.