iglide® FDM filament: an industrial alternative to standard materials

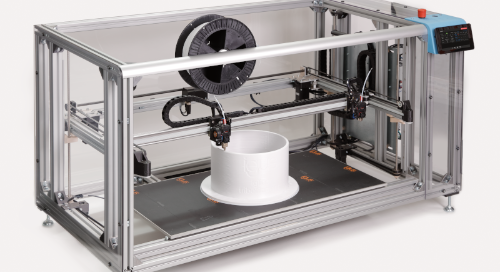

3D printing is a widely popular and rapidly growing manufacturing method, with fused deposition modeling (FDM) being the most popular type of 3D printing.

The popularity of FDM printing has led to countless varieties of printing filaments to be developed by various manufacturers, all with their own properties, advantages, and disadvantages. igus® is one such manufacturer of FDM filament.

Read on to learn what sets iglide® tribofilaments from igus apart from the alternatives, and discover some of the many applications and use cases only possibly with wear-resistant iglide filaments.

Misconceptions about 3D-printed components

Even with the rising popularity of 3D printing, there are many misconceptions surrounding 3D printing and how effective 3D-printed parts can be in industrial applications. It’s often assumed the materials used in 3D printing — especially FDM printing — simply aren’t strong enough to withstand high loads, speeds, and wear.

FDM filaments from igus challenge these misconceptions. Their wear-resistant, self-lubricating properties make them ideal in industrial applications with frequent movement. Compared to standard filaments, iglide filaments last up to 50 times longer in moving applications. They even offer a similar service life as injection molded iglide components.

Read the white paper below to learn more about how iglide 3D printing materials compare to standard printing materials and injection-molded components.

A closer look at iglide filaments

As mentioned previously, iglide filaments offer excellent wear-resistance and can be used effectively in moving applications. Several different material variants are available, each with additional unique properties suited for specific areas of application. Among these, there are three particularly popular and wide-ranging choices:

These three materials are considered “all-rounders” due to their wide range of possible applications and ability to be processed as easily as standard PLA and PETG filaments. Print profiles for processing these materials on select Bambu Lab, Prusa, and Ultimaker printers are even available for download to ensure proper processing. These materials are also available with either 1.75mm or 3mm diameters.

Other features of select materials from the iglide filament range include FDA and EU compliance for food safety, flexural strengths of up to 237 MPa and flexural modulus of elasticity of up to 11.5 GPa, and resistance to application temperatures as high as 170°C (338°F).

These properties ensure iglide filaments can be used in applications across countless industries and meet demanding requirements with ease. Multi-material printing can also be utilized for unique situations where different areas of a part need to meet different requirements.

Non-industrial FDM filaments

Most FDM filaments are designed to be used by hobbyists, and therefore don’t have the required wear resistance and strength to be used in industrial applications where movement and friction can be constant.

This is simply due to a different set of priorities for hobbyist applications — primarily ease of processing, printing speed, and material appearance. To meet these needs, factors like material strength and service life are ignored.

Since these non-industrial materials are some of the most widely known and most popular, there’s naturally less awareness of industrial alternatives and the benefits they offer that can’t be replicated with “normal” filaments.

Industrial FDM applications

Even though the majority of 3D printing projects are hobbyist rather than for industrial use, this doesn’t mean industrial applications aren’t also frequent. Whether it’s providing spare parts to replace failed components, rapid production of newly designed parts, or improving existing designs, 3D printing can be an invaluable resource in industrial applications.

igus can not only produce complex custom parts and geometries through 3D printing, standard parts with custom dimensions can also be produced. Anything from bearings, lead screw nuts, gears, and more can all be custom manufactured from iglide filaments with igus’ 3D printing service.

Related: igus 3D printing application stories

Conclusion

Understanding the difference between industrial and non-industrial FDM filaments is absolutely essential when selecting a filament for your own application. Design considerations and priorities are completely different between these two categories, and trying to use a non-industrial filament within an industrial application will only lead to rapid part failure.