Improving furniture design with dry-running slewing rings

Furniture having moving components is far from a recent development. Various types of chairs, tables, desks, and more have long utilized motion for improved comfort and functionality. In particular, swiveling motion is used frequently in furniture.

While metallic ball bearing slewing rings are a common solution to achieving swiveling motion in furniture, they’re not the ideal choice. High-performance plastic slewing rings from igus are more robust, offer better, more reliable performance, and can be used for outdoor and marine furniture without risk of corrosion or excessive wear.

Read on to learn more about igus’ PRT slewing rings and the benefits they offer over ball bearing alternatives.

PRT slewing ring overview

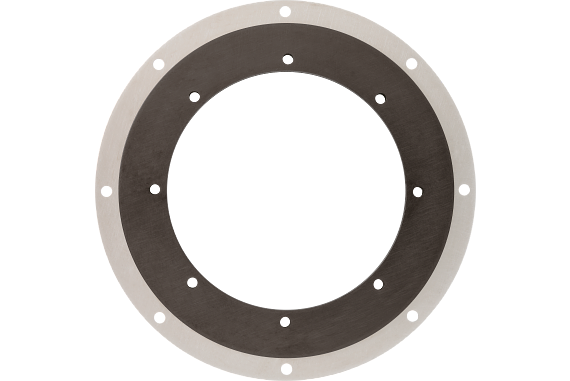

PRT slewing rings from igus make use of self-lubricating iglide materials to achieve long-lasting, maintenance-free performance. The materials are also lightweight and durable, perfect for designing easily movable furniture. The sliding elements also make PRT an excellent choice for office furniture, as noise is kept to a minimum due to the low-friction performance. Liner replacements can also be purchased separately from the slewing ring housings as needed.

Ball bearing slewing rings are a noisier, heavier alternative to sliding systems and require frequent greasing to maintain optimal performance. These factors all have a negative impact in furniture design and operation and lead to a lower quality, less desirable final product.

Infographic: PRT slewing rings at a glance

Slewing ring accessories

The PRT line of slewing rings includes a range of various accessories such as clamps, spacer rings, and angle stop sets. The clamps and angle stop sets allow for stop points to be set, preventing complete 360-degree rotation if it’s not suitable for the application.

Select PRT slewing rings are also available with detent locking mechanisms that can be individually defined. These mechanisms have a holding force of 350N, allowing precise adjustment of the slewing ring even under high loads.

Spacer rings allow PRT slewing rings to be installed onto flat surfaces more easily, without the need for additional undercuts or cutouts. This helps to minimize production costs and ensure PRT slewing rings can be installed into the widest possible range of furniture.

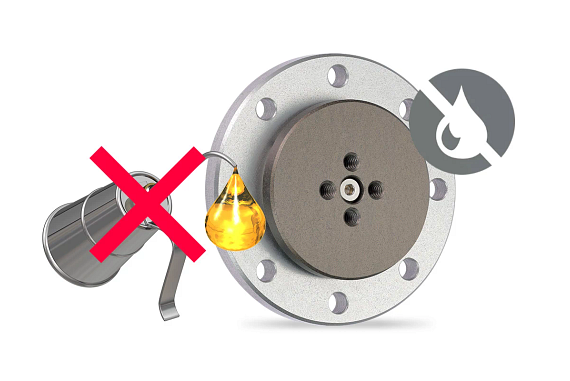

Grease-free performance

The plastic liners used within PRT slewing rings are tribologically enhanced, meaning solid lubricants are embedded throughout the liner. These solid lubricants ensure constant and even lubrication during operation without the need for additional maintenance.

Similar slewing ring systems that utilize ball bearings will require frequent relubrication with grease to maintain optimal function. If they aren’t adequately maintained, the likelihood of premature wear or component seizure increases.

White Paper: The True Cost of Bearing Lubrication

A lack of maintenance is ideal in furniture design, where customers expect to be able to purchase furniture and immediately put it to long-term use. Dozens of hours of simple relubrication can be eliminated from an office building or other large space over the lifespan of furniture using PRT slewing rings in place of ball bearing slewing rings.

Quiet operation

Another benefit of using sliding plastic elements rather than ball bearing systems is a significant reduction in noise produced during operation — a key feature for the furniture industry, where customers expect furniture to move silently.

The rolling motion of metallic rollers or balls naturally generates more noise than sliding plastic elements, which will be heard during routine movements even when well maintained. This noise will get even worse if maintenance is performed inadequately or skipped altogether.

In office environments or other workspaces where noise needs to be minimized, having loud furniture can be both a nuisance and a distraction for employees. While it seems like only a simple issue, it’s one that can make a huge difference in employee mood and outlook. Opting to use silent components in furniture will avoid these issues and keep end users satisfied.

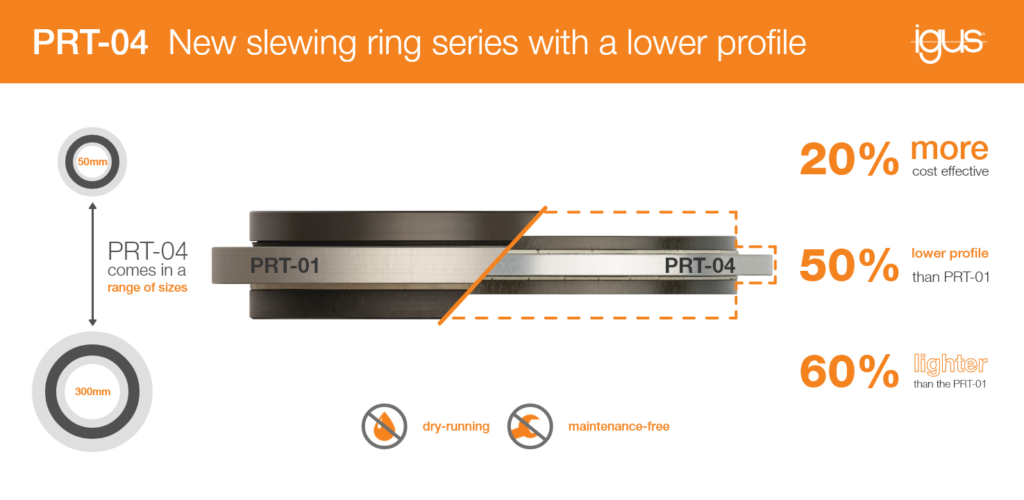

Compact design

PRT slewing rings from igus all utilize a compact, space-saving design. The sliding elements within the slewing ring make this design possible, and enable installation in tight spaces. The PRT-04 is one of the lowest profile slewing rings available from igus, with a 50% reduction in size relative to the standard PRT-01. The PRT-06 is even more compact than the PRT-04, with a height reduction of over 50% and further weight reduction, perfect for furniture applications where weight is a primary concern.

Ball bearing slewing rings are more likely to require greater installation space than sliding slewing rings as the rolling elements are larger and require a more robust housing to fit them. This can make installation in limited spaces more difficult, if not impossible.

Corrosion-resistant

In furniture that faces exposure to the elements, such as patio or marine furniture, resistance to moisture and corrosion is essential. Since the sliding elements in PRT slewing rings are plastic they completely resist corrosion. Additionally, the rings are available in corrosion-resistant materials like aluminum, stainless steel, and solid plastic.

Metallic ball bearing slewing rings are less equipped to handle exposure to moisture due to their all-metal composition and use of lubricating grease. Risk of corrosion due to water or salt exposure is increased with the all-metal composition, and exposure to water poses the risk of washing away lubricants.

Marine furniture is a rapidly growing area of application, and one that poses some of the harshest conditions for moving components. Therefore, demand for components like PRT slewing rings that can not only withstand these conditions but also add functionality to furniture will greatly increase in the coming years.

Conclusion

There’s a lot to consider when designing furniture: ergonomics, comfort, cost, accessibility, and more. These factors will continue to become more relevant as furniture becomes more and more advanced and implements additional moving components. PRT slewing rings from igus are the ideal way to handle swiveling motion in furniture due to their many advantages over other common slewing ring products.