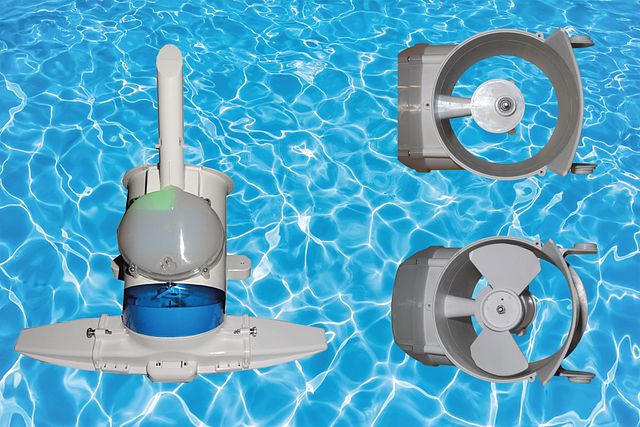

Improving robotic pool cleaners with self-lubricating polymer bearings

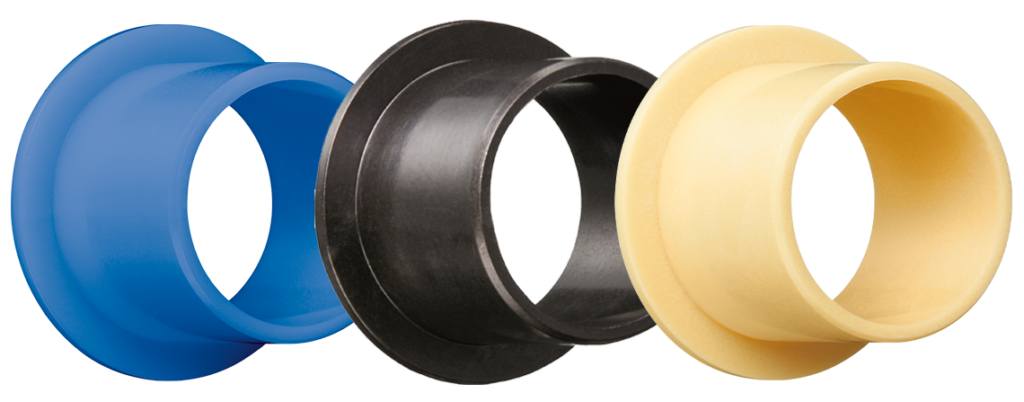

As technology continues to rapidly advance, the design of robotic pool cleaners has undergone significant transformations to meet increased demands for efficiency, reliability, and durability. One critical innovation in this field is the incorporation of self-lubricating polymer bearings in pool cleaning robot design. These bearings offer a range of advantages and benefits that enhance the performance and longevity of pool cleaning robots, making them a smart and popular choice among manufacturers and users alike.

Maintenance-free operation

Traditional metal bearings often require regular lubrication to maintain optimal performance and prevent wear. In contrast, self-lubricating polymer bearings are designed to operate without the need for periodic maintenance or consistent relubrication. These bearings are a homogenous blend of base polymers, reinforcing fibers, and solid lubricants, ensuring smooth and consistent operation throughout their lifespan. This significantly reduces the need for manual upkeep, saving time and money for pool owners while keeping excess grease away from pools and the surrounding environment.

Enhanced durability in wet and outdoor environments

Robotic pool cleaners operate in a unique environment characterized by constant exposure to water, pool chemicals, and UV radiation. igus’ self-lubricating polymer bearings are specifically designed to withstand such conditions. They are resistant to corrosion, chemical damage, and UV damage, all while offering low moisture absorption. This durability ensures that the bearings remain functional even in the harshest aquatic settings.

Improved energy efficiency

Efficient energy usage is a critical factor in the design of pool cleaning robots. Self-lubricating bearings reduce friction between moving parts, minimizing energy loss during operation. This lower friction not only enhances the robot’s performance, but also reduces the strain on its motor, leading to longer battery life and lower energy consumption.

Blog: What are the requirements for an underwater motor?

Quiet operation

Noise can be a significant concern for robotic pool cleaners, especially in residential settings where peace and quiet are valued. Self-lubricating polymer bearings contribute to quieter operation by minimizing friction and vibration within the robot’s mechanisms. This makes the cleaning process less intrusive and more enjoyable for users.

Increased lifespan of components

The reduced friction and wear provided by self-lubricating polymer bearings extend the lifespan of the robot’s internal components. By minimizing the need for replacements and repairs, these bearings contribute to the overall cost-effectiveness of pool cleaning robots. Users can enjoy reliable performance for longer periods without worrying about frequent breakdowns.

Applications in modern robotic pool cleaners

Modern robotic pool cleaners leverage self-lubricating polymer bearings in various critical components, such as drive systems, brushes, and water pumps. Their ability to perform reliably under continuous operation ensures thorough cleaning of pool surfaces, walls, and waterlines.

Application Story: xiros® Plastic Radial Ball Bearings in Pool Cleaner

Conclusion

The integration of self-lubricating bearings in pool cleaning robots represents a significant leap forward in terms of design and functionality. By offering maintenance-free operation, enhanced durability, improved energy efficiency and a quieter cleaning process, these bearings address many challenges faced by traditional systems. As the demand for smarter and more reliable pool cleaning solutions grows, self-lubricating polymer bearings will continue to play a pivotal role in advancing the capabilities of these essential devices.