A complete guide to plastic injection molding in 2025

Injection molding is a manufacturing process that has been around for more than 150 years. Today, it is more popular than ever thanks to continuous innovation and material improvements. This blog will explain what injection molding is and some of its benefits and unique applications.

What is injection molding?

Injection molding is one of the most common modern day manufacturing processes. It’s primarily used to create plastic parts in bulk for countless applications and industries.

The injection molding process consists of an injection molding machine melting down plastic granules and injecting the melted plastic into a mold where it can cool, forming the final part. However, before any of this can happen, the product must be designed and the mold must be created.

Injection molding is the most efficient production method — both in terms of cost and time — for large-scale production of roughly 10,000 or more parts.

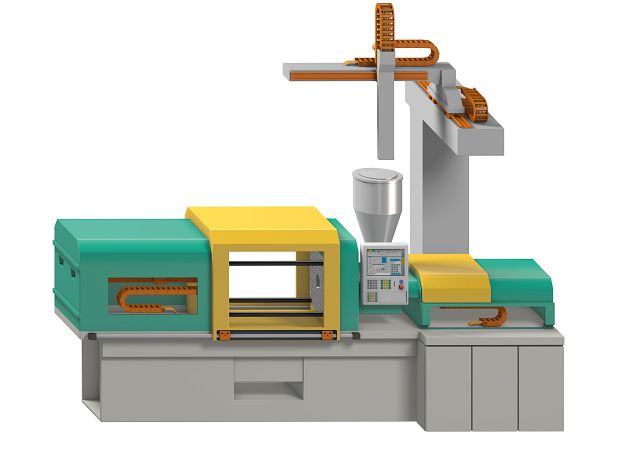

Machinery and tools used in injection molding

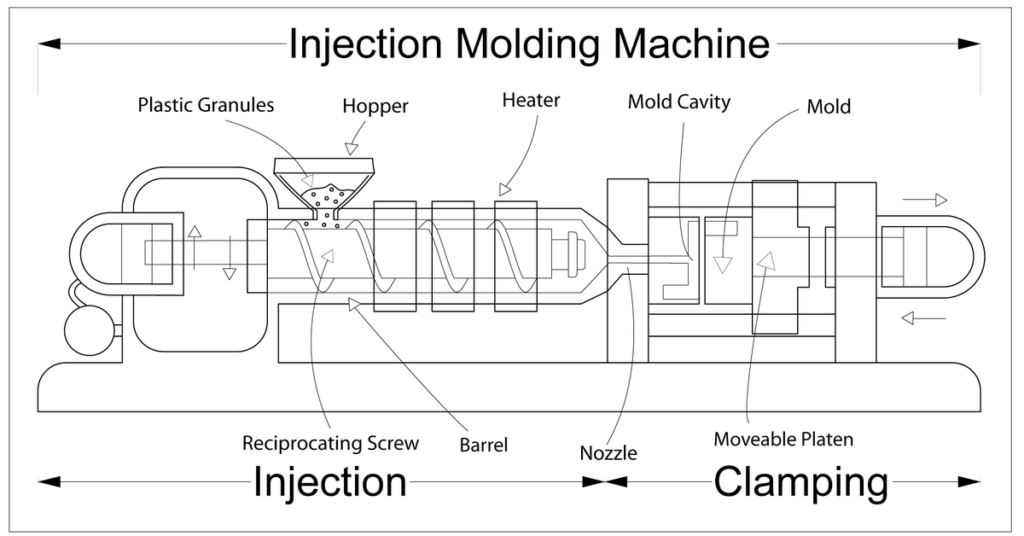

Injection molding machines are complex devices made up of several different parts, each serving an essential function in the creation of plastic components. Learn more about them below.

- Hopper: The hopper is where plastic granules are fed into the injection molding machine. A valve on the hopper is used to control the flow of material into the barrel of the machine.

- Barrel: The barrel of an injection molding machine is the chamber where plastic material is heated up to a molten consistency.

- Heating element: Heating elements around the barrel of the machine produce the heat to melt down the plastic granules. The temperature of the heating element can be controlled and changed depending on the specific material being used.

- Screw: Housed within the barrel, the screw is the component of the machine that funnels the plastic material towards the nozzle. A screw is used to help evenly distribute heat and mix the granules as they melt.

- Nozzle: The nozzle of an injection molding machine is where the molten plastic is injected into the mold. Modern injection molding nozzles can filter out foreign materials and assist in mixing — particularly helpful in ensuring additives are adequately dispersed.

- Mold: The molds used for injection molding are made up of two individual pieces that are clamped together during production. A hollow area in the center of the mold — the cavity — is where the molten plastic is injected and then cooled to form the final product. Molds are also often designed with cooling channels used to strategically manage the heat levels of specific areas of the mold.

- Clamping unit: The primary purpose of the clamping unit is to keep the two halves of the mold clamped together securely while injection is happening. Hydraulic clamps are extremely common, but more recently electric clamping systems have grown more popular due to their power efficiency, higher accuracy, and oil-free design.

- Ejector system: Ejector pins or plates are used to eject the finished plastic part from the mold. Some parts may need finishing, which is handled separately from the injection molding machine.

Types of injection molding materials

The world of plastics is deep and varied, with dozens of different types available, each with unique characteristics and ideal operating conditions. Two primary “classes” of plastics are used in injection molding: thermoplastics and thermosetting plastics.

Thermoplastics

Thermoplastics are plastics that can be repeatedly melted, cooled, and remelted, making them ideal for injection molding processes as any waste can easily be reprocessed into granulate and used again.

Below are some of the most commonly used thermoplastics:

- Polycarbonate

- Polypropylene

- Polyethylene

- Polyoxymethylene (POM/acetal)

Thermosetting plastics

Thermosetting plastics, unlike thermoplastics, cannot be melted down again once they’ve hardened through curing. However, thermosetting plastics are generally stronger than thermoplastics and perform better in high-temperature applications.

Below are some of the most common types of thermosetting plastics:

- Polyester

- Polyurethane

- Polyimide

- Epoxy

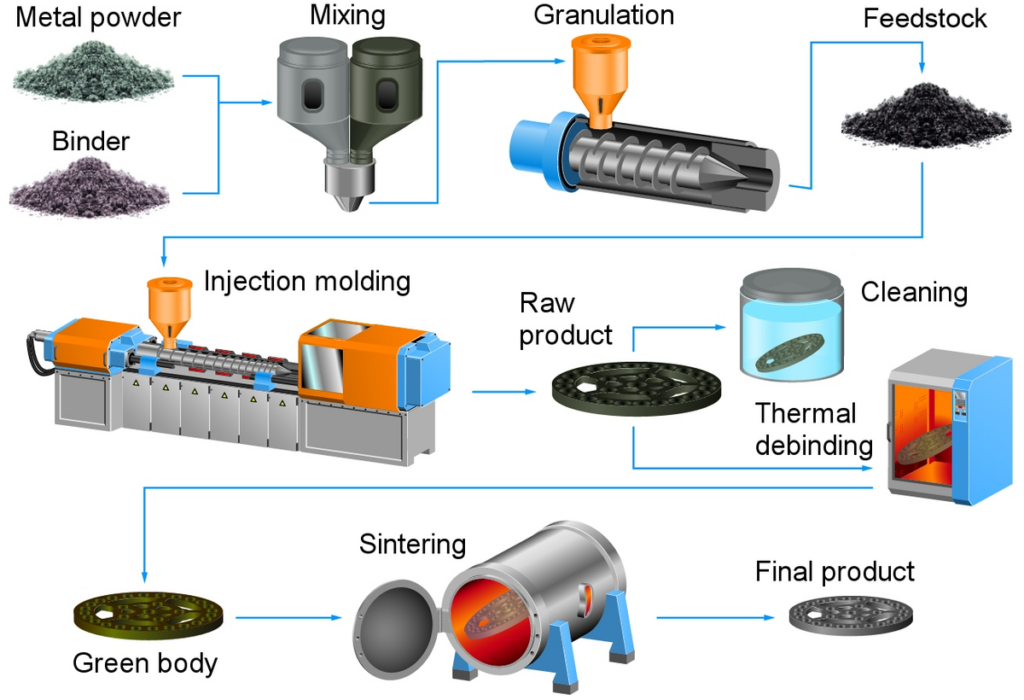

Metals for injection molding

While still a relatively niche process compared to plastic injection molding, metal injection molding (MIM) allows for metal parts below 100 grams to be injection molded. In MIM metal powders are mixed with polymer binding material, which is removed from the piece as part of finishing.

Prior to this process — called debinding — the part is referred to as a “green part”, and after debinding it’s referred to as a “brown part”. Once the part has gone through debinding, it is still porous and must be sintered to remove pores and achieve the final, fully dense product. Some shrinkage may occur during sintering, and should be planned for when creating the initial mold. This typically means designing the mold to be 15–20% larger than the final product.

How does injection molding work?

- Design & mold creation: The first step in injection molding is the creation of the mold. Molds are most often machined, particularly for complex parts, but they can also be 3D printed from high-performance plastics.

- Clamping: Once a final mold has been created, it’s placed into the injection molding machine and clamped into place. Clamps ensure the mold will remain firmly in place during the injection process.

- Injection: After the mold is in place, plastic granules are melted down and injected into the mold. Vents in the mold allow any air to be completely forced out of the mold (dwelling), leaving just the plastic material behind.

- Cooling: The injected plastic needs to cool within the mold to retain its shape once it’s ejected. This can range from seconds to minutes, depending on the design of the part being made.

- Clamp opening & ejection: Finally, once the part has cooled and the clamp is opened, it can be ejected from the mold. This is done either with ejection pins or plates. From here, the ejected part will undergo any necessary finishing before being shipped to customers.

Advantages of injection molding

The popularity of injection molding is in no small part due to the numerous advantages it offers over other production methods like machining and 3D printing. Below are a few of the most impactful.

Low cost-per-part

Injection molding costs primarily consist of the mold, the raw material used, and any finishing processes that need to be performed. The price of a mold can range between $100 and $100,000, depending upon the complexity of the mold and how it’s produced.

While this initial cost can be extremely high, the costs of raw materials and finishing processes are significantly lower. The more a single mold is used to create parts, the more profitable the process becomes. This is why injection molding is most often used when producing runs of thousands of parts, as the cost per part becomes extremely low.

Rapid production cycle

Once a mold has been created, the rest of the process is quick. For each part produced, the entire process typically takes between two seconds and two minutes, depending on the complexity of the part and the material used.

Minimal waste

Compared to machining and 3D printing, injection molding produces minimal waste. Any waste that is generated during the injection molding process can be reground and used again in the future, reducing total material waste even further.

Wide range of applications

Injection molding is used to create countless different items, from consumer products like trash bins and chairs to components used in manufacturing like bearings and cable carriers. This versatility is unmatched by other production methods.

Injection molding at igus

igus, as a producer of plastic components, utilizes injection molding extensively. Earlier in 2024, a new injection molding facility was opened in Rumford, RI, with the goal of bringing parts production in-house for the U.S., reducing reliance on international subsidiaries for product imports.

While injection molding is not typically thought of as a viable production method for non-standard parts, igus has developed a service for this exact situation: the FastLine injection molding service.

The FastLine service makes it possible for customers to order large quantities of bearings, washers, and rollers in non-standard dimensions. Parts ordered through the FastLine service can be shipped in as little as two weeks.

As mentioned above, igus develops and produces all of the plastic materials used in its products. This gives igus the freedom to design unique plastics for niche applications while retaining the performance properties that set our products apart from similar offerings.

Infographic: Choosing your custom parts manufacturing method

Conclusion

Injection molding has proven itself as an indispensable manufacturing process, offering unparalleled efficiency, precision, and versatility across countless industries. From large-scale production runs to custom, low-volume projects, its adaptability ensures it remains a cornerstone of modern manufacturing. As technology evolves, injection molding will undoubtedly continue to play a pivotal role in shaping the future of manufacturing, offering solutions that are both practical and forward-thinking.